6 voltage programming shunt, 7 control board replacement, 4 ignition circuits – Alpha Technologies AlphaGen 3.5_5.0kW Kohler COM5 User Manual

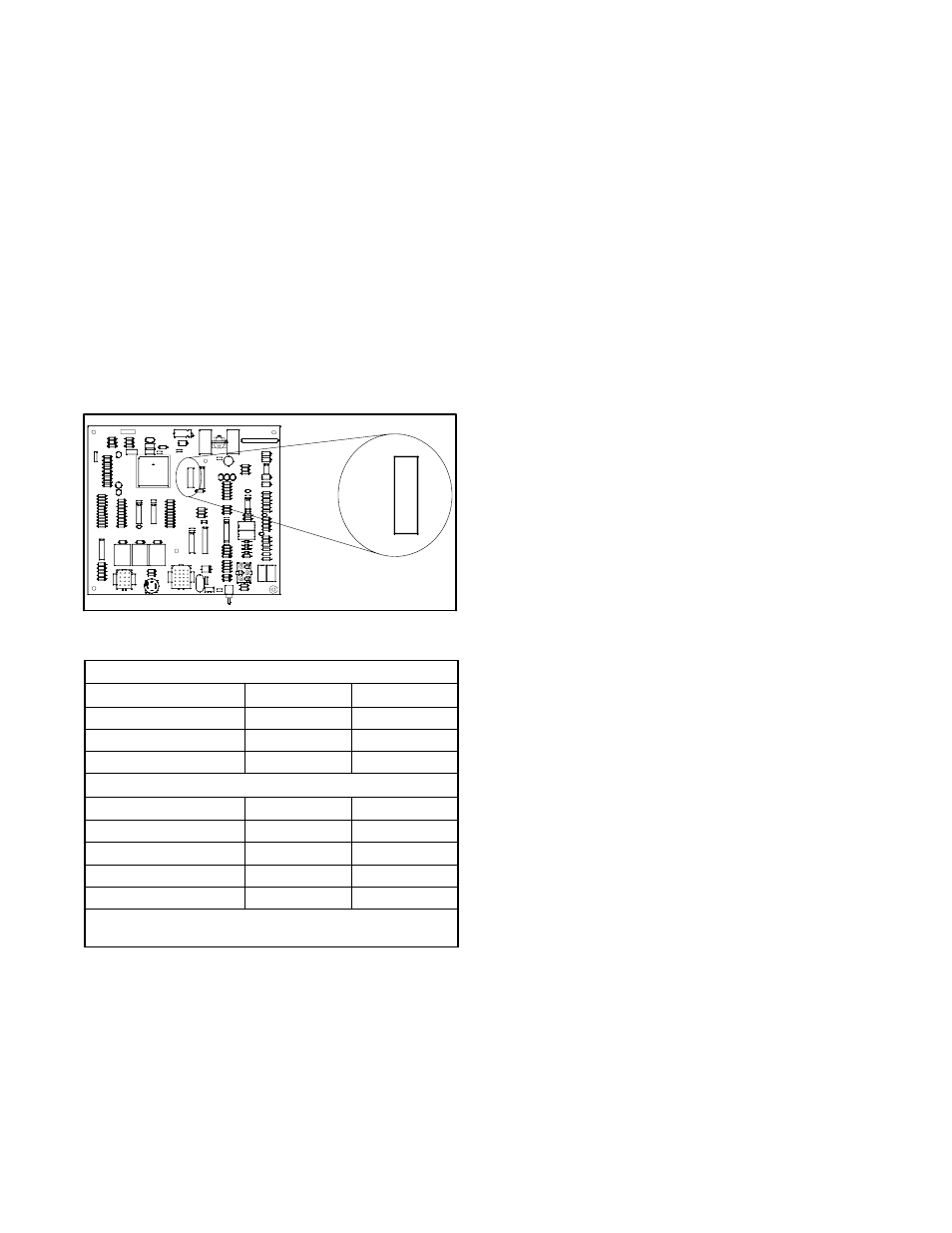

Page 60: Figure 6-6 programming shunt location, Figure 6-7 jumper configurations, Notice, Check that all plug connections are secure, Power selection jumpers kw rating jp1a jp1b

TP-6482 8/06

60

Section 6 Controller Operation and Test

6.5.4

Ignition Circuits

Move the generator set master switch to the START

position. If the engine cranks but does not start, check

for voltage from lead 70 to ground at terminal B on the

ignition module and at the positive terminal of the

ignition coil. If no voltage is present during cranking,

replace the controller circuit board. If the ignition system

is receiving 12 VDC, check the spark plug and test the

other ignition system components.

6.6 Voltage Programming Shunt

Control board GM22402 uses a programming shunt for

voltage selection. See Figure 6-6 for the programming

shunt location. Set programming shunts JP1A through

JP1D to select the generator set kW and voltage as

shown in Figure 6-6 and Figure 6-7.

GM22402

3.5 5.0 7.5

R51

R52

D26

D27

D28

R53

SW1

D29

R43

MC1413BP

D7

D9

D8

D5

D6

17

P1

1 3

K110 12

D20

F1

D21

TYPE

12.5A

250V

FST1

K2

K3

P2

4

V1

20

R48

C24

R32

C19D23

D24 4

D22R45

R46

R47

Z1

R44

6

R3

R13

U1

R14

R15

R17

R16

D4

D3

C1

R11

R12

R10

R9

R8

R100

R7

R6

R5

R4

P4R2

+

D17

C4

C5

D16

D15

+

C3

D14

D13

+

+ U4

D18

C9

D19

74HC14 U574HC14

U3

LED1

D12

D11

Q1

FAIL

GEN

R

C12

C8

87C196KB16

C18

U7

L293D

U8

R25

R28

R26

R27

R23

R24

R22

C16

C17

R30

R31

C23

L297/1

R42

LM2902N

C29

+

U9

R39

R40

R41

C28

JP1G

8

R21

R20

JP1H

R29

9

JP1B

JP1D

JP1E

JP1F

JP1C

1

JP1A

JP1

16

U6

R33

R37

R38

R36

R35

R34

C21

Q2 R50

Q3Q4

D25

R49

D1

U2

R1

D2

C2

R18

C7

C6

R19

D10

C11

1

+

C10

Y1

C14

+

C15

C13

VR1

C20 +

R63

C37

R54

R55

1

R64

R65

P3

3 C36

+

LM2903N

C35

R62

D33

Z3

Z2

R61

D32

D31

D30

R60

C27 C34

C33

R56

R59

R58

R57

C26

U10

C25

+

C32 +

U11MAX680

C31

C30

BARCODE

+

JP1G

8

JP1H

9

JP1B

JP1D

JP1E

JP1F

JP1C

1

JP1A

JP1

16

Figure 6-6

Programming Shunt Location

Power Selection Jumpers

kW rating

JP1A

JP1B

3.5

OUT

OUT

5.0

OUT

IN

7.5

IN

OUT

Voltage Selection Jumpers

Voltage Rating, VDC

JP1C

JP1D

24

OUT

OUT

36

OUT

IN

48

IN

OUT

96

IN

IN

Note: Jumpers JP1E and JP1F have no function.

Jumpers JP1G and JP1H are for factory use only.

Figure 6-7

Jumper Configurations

6.7 Control Board Replacement

NOTICE

Electrostatic discharge damage. Electrostatic discharge

(ESD)

damages

electronic

circuit

boards.

Prevent

electrostatic discharge damage by wearing an approved

grounding wrist strap when handling electronic circuit boards

or integrated circuits. An approved grounding wrist strap

provides a high resistance (about 1 megohm), not a direct

short, to ground.

If the controller tests in Section 6 or the troubleshooting

procedures in Section 4 indicate that the control board

needs to be replaced, follow these guidelines:

D

Keep the new board in its protective wrapping until

installation.

D

Wear a grounding strap while handling the circuit

board to prevent damage to the circuit board

components.

D

Set the programming shunts for kW and voltage. See

Section 6.6.

D

Check that all plug connections are secure.

D

Calibrate the voltage after installing the board.

The new circuit board must be calibrated after

installation. Use the following procedure to calibrate the

board.

Installation Procedure

1. Place the generator set master switch in the OFF

position.

2. Disconnect the power to the battery charger, if

equipped.

3. Disconnect the generator set engine starting

battery(ies), negative (--) lead first.

4. Open the enclosure to access the control board.

5. Disconnect all connectors to the control board, and

remove the board from the enclosure.

6. Before

installing

replacement

control

board

GM22402, install the jumper(s) (294634) as shown

in Figure 6-7 to obtain the rated power (kW) and

voltage for the generator set. Zero (0) to three

jumpers are required, depending on the selected

voltage and power ratings. See Figure 6-6 for the

jumper locations.

Note: Verify that connector P2 is not connected to

the board during jumper installation or

removal.