4 lubrication system – Alpha Technologies AlphaGen 3.5_5.0kW Kohler COM5 User Manual

Page 24

TP-6482 8/06

24

Section 3 Scheduled Maintenance

Return to Operation

Slide the generator set back into the enclosure and

reconnect the exhaust pipe, fuel system, and wiring

harnesses as described below.

1. Verify that the generator set master switch is in the

STOP position.

2. Slide the generator set back into the enclosure.

3. Install the exhaust gasket and reconnect the

exhaust pipe.

4. Reinstall the enclosure back panel.

5. Reconnect the fuel line and turn on the fuel supply.

6. Check for fuel leaks.

7. Reconnect the engine wiring harness, load leads,

and battery harness.

8. Reconnect the generator set engine battery

harness.

9. Move the generator set master switch to the center

(AUTO) position to return the generator set to

standby service.

10. Reinstall the generator set compartment front

panel.

11. Reinstall the enclosure door.

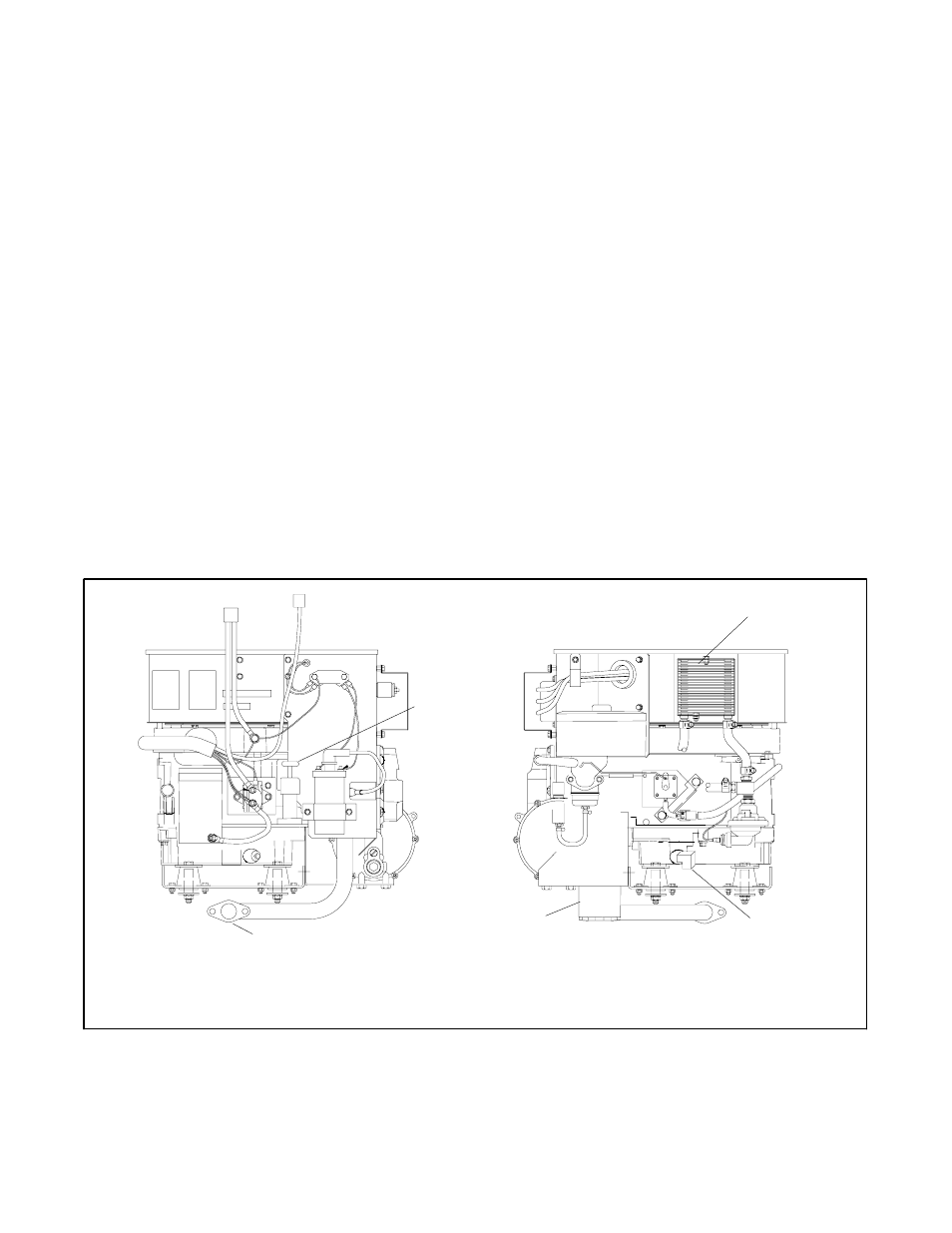

3.4 Lubrication System

See the service schedule in Section 3.2 for oil change

and oil filter replacement intervals. See Figure 3-4 and

Figure 3-5 for the oil drain, oil check, oil fill, and oil filter

locations.

The list of routine service parts in the

Introduction of this manual shows the oil filter part

number.

3.4.1

Oil Check

The generator set is shipped with oil. Before operating a

new generator set check the engine oil in the crankcase.

See Figure 3-4 and Figure 3-5. Verify that the oil level is

at the F mark on the dipstick. See Section 3.4.2 for

engine oil recommendations.

Do not check the oil level when operating the generator

set. To obtain the most accurate oil level reading, shut

down the generator set and wait several minutes before

checking the oil.

M-337000B-B

1

5

4

2

1. Oil check, fill

2. Exhaust pipe connection

3. Oil cooler

4. Oil drain

5. Oil filter

3

Figure 3-4

Lubrication System, Specification Numbers PA-195023 and PA-195027