5 control board tests – Alpha Technologies AlphaGen 3.5_5.0kW Kohler COM5 User Manual

Page 59

TP-6482 8/06

59

Section 6 Controller Operation and Test

6.5 Control Board Tests

Use the troubleshooting procedures in Section 4 to

diagnose generator set and engine problems. If the

troubleshooting procedures indicate a problem with the

controller circuit board, use the tests in this section to

check the board.

Refer to the wiring diagrams in Section 8 when

troubleshooting the generator set control circuit board.

Circuit board components cannot be repaired or

replaced; if the troubleshooting process reveals a faulty

component on the circuit board, replace the board.

Note: Use an ohmmeter or continuity tester to check for

shorts or open leads in the wiring harnesses

before replacing the controller circuit board or

other system components.

Disconnect the generator system from the remote

control system at plug P6 and use the generator set

master switch to operate the generator set.

If the

generator

set

operates

normally

when

P6

is

disconnected, then the problem is with the remote

control system. Refer to the manufacturer’s instructions

for the remote control system to troubleshoot the

problem.

If the problem persists after P6 is

disconnected, use the troubleshooting procedures in

this manual to diagnose the problem.

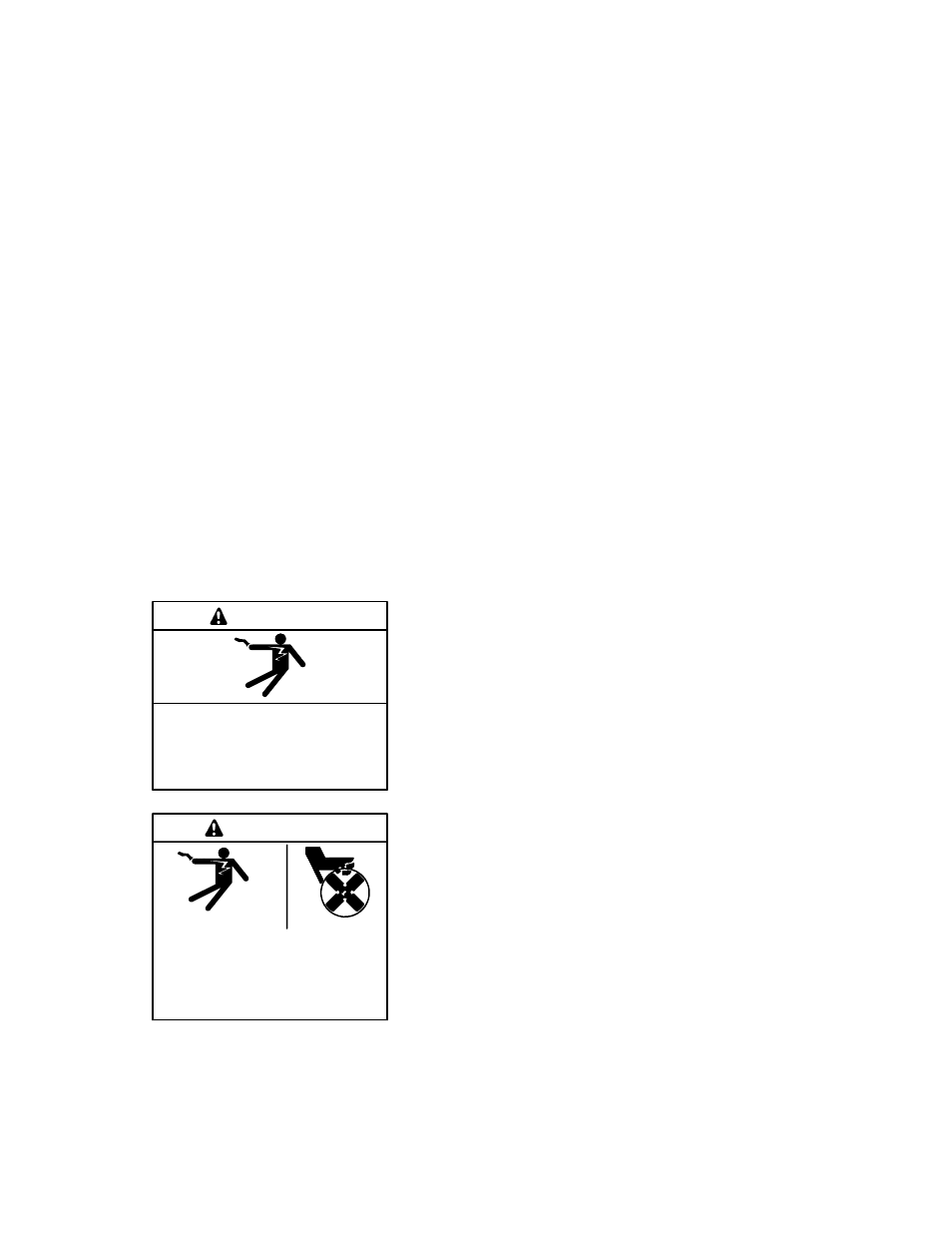

Hazardous voltage.

Will cause severe injury or death.

Only authorized personnel should

open the enclosure.

DANGER

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

are in place.

Moving rotor.

WARNING

Servicing the generator set when it is operating. Exposed

moving parts can cause severe injury or death. Keep

hands, feet, hair, clothing, and test leads away from the belts

and pulleys when the generator set is running.

Replace

guards, screens, and covers before operating the generator

set.

Short circuits.

Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage.

Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

6.5.1

Fuel Control Circuit

Move the generator set master switch to the START

position and check for 12 VDC on pin P5-1 (lead 70) of

the fuel valve connector. If the valve receives voltage

but does not open, replace the valve.

If there is no voltage to the valve, check the battery

voltage, battery connections, and ignition system (see

Section 5.5). If the battery and ignition system function

correctly but the fuel valve does not receive voltage,

replace the controller circuit board.

6.5.2

Speed Sensing and Governor

(Throttle Control) Circuits

The controller monitors the AC voltage produced by the

stator to sense and control the engine speed. If the

engine speed varies erratically, test the governor

operation as described in Section 5.4. If the tests show

that the erratic operation is not caused by a faulty

governor, replace the controller circuit board.

6.5.3

Start Circuits

Move the generator set master switch to the START or

RUN position. If the engine does not crank, check the

following components.

1. Check the battery voltage. Recharge or replace a

weak or dead battery.

2. Check for 12 VDC to the starter motor. Also verify

that the starter motor is grounded. See Section 8,

Wiring Diagrams. If the starter motor is receiving

voltage but not functioning, replace it. If there is no

voltage to the starter motor, check the harness and

connections and then proceed to step 3 to check

the starter (crank) relay.

3. Check for 12 VDC to the crank relay.

See

Section 8, Wiring Diagrams. If the crank relay is

receiving voltage but not functioning, replace it. If

there is no voltage to the crank relay, check the

harness and connections.

4. Check for 12 VDC from the control board at P2-1. If

there is no voltage, replace the controller circuit

board.