Alpha Technologies AlphaGen 3.5_5.0kW Kohler COM5 User Manual

Page 51

TP-6482 8/06

51

Section 5 Component Testing and Adjustment

8. Clean the hose fitting with a dry cloth or brush,

apply fresh pipe sealant, and install it into the LP (or

natural gas) inlet.

9. Slide the hose onto the hose fitting and secure it

with the clamp.

10. Turn on the fuel supply and check for leaks using a

gas leak detector.

11. Reconnect the battery harness.

12. Install the generator compartment front panel. Set

the generator set master switch to the AUTO or

center position to return the generator set to

standby service.

13. Replace the enclosure door.

5.7.4

Fuel System Recalibration

The fuel metering valves are factory-set to meet

emissions requirements and sealed to discourage field

adjustments. If the fuel system requires recalibration,

only trained, authorized service technicians may adjust

the fuel metering valves. Always use an oxygen sensor

and an exhaust tube with an oxygen sensor port,

available from the generator set manufacturer, when

adjusting the fuel metering valves.

Note: Changing the fuel system adjustments may void

the emissions certification.

Fuel

system

recalibration requires

the following

equipment, which is available from Kohler Co.:

D

Oxygen sensor

D

Test exhaust pipe with oxygen sensor port

See Maintenance and Service Parts in the Introduction

section of this manual for the equipment part numbers.

Follow the instructions in Section 5.1 to remove the

generator set and operate outside the enclosure.

Fuel System Recalibration Procedure

1. Run the generator set at full load and check the

oxygen sensor reading. At full load, the oxygen

sensor

output

voltage

should

be

between

0.75 VDC and 0.85 VDC.

2. If adjustment is required, remove seal on the fuel

metering valve and adjust the valve to obtain an

oxygen sensor reading between 0.75 VDC and

0.85 VDC. See Figure 5-20 for the fuel metering

valve location.

3. Reseal the valve after adjustment.

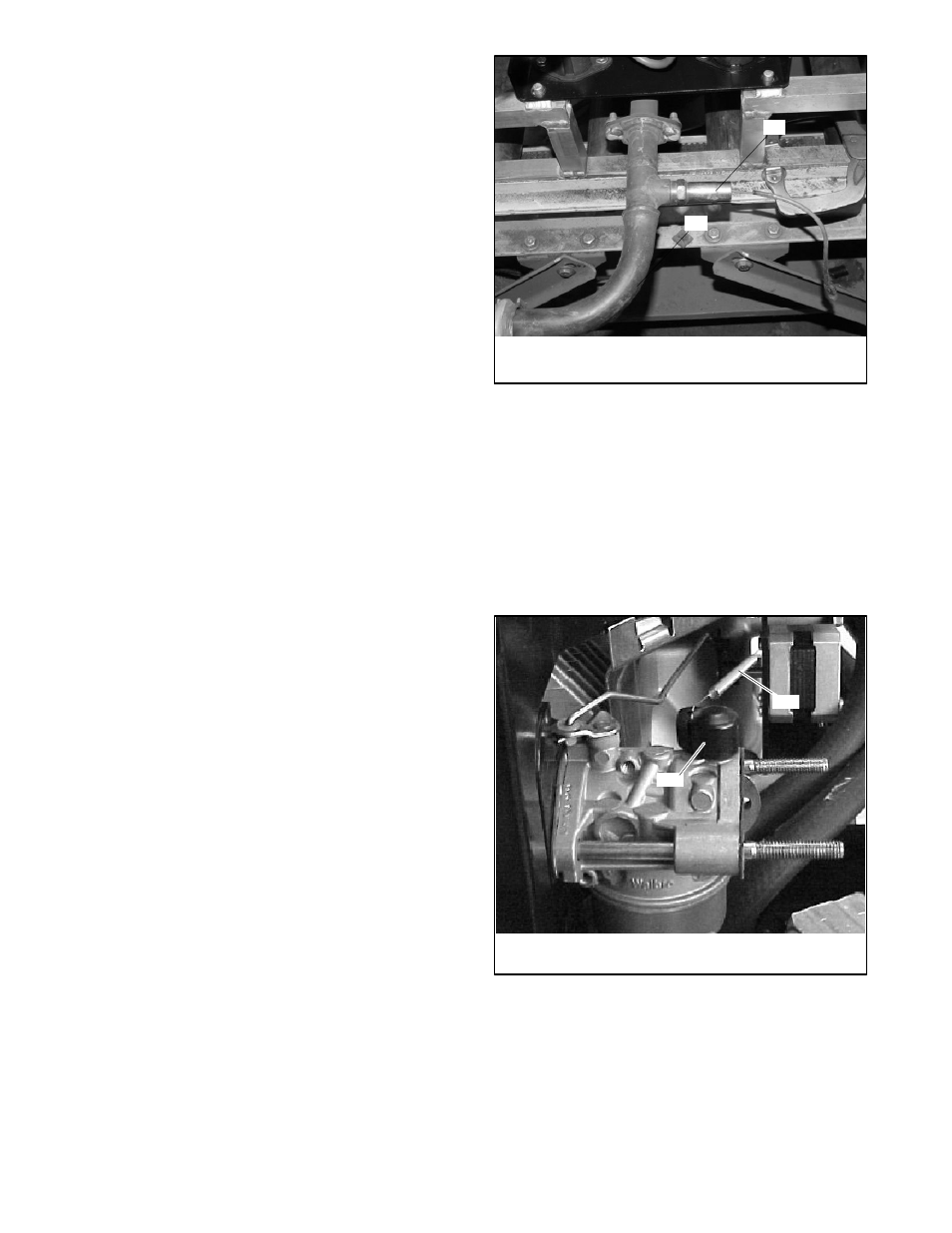

1

tp6092

1. Oxygen sensor

2. Exhaust tube GM23580

2

Figure 5-23 Exhaust Tube and Oxygen Sensor

5.7.5

Choke

Some engines are equipped with a choke, which is held

open at all times by the choke spring shown in

Figure 5-24.

If the engine is equipped with a choke, identified by the

knob shown in Figure 5-24, check that the spring is

attached and holding the choke open.

1

2

TP5632721

1. Choke spring

2. Choke knob

Figure 5-24 Choke Assembly (not included on all

engines)

Generator sets built after June, 2001, do not have a

choke assembly and, therefore, do not require the

spring. Choke solenoid service kit GM42302 can be

installed to improve engine starting in cold weather. See

TT-1422 for more information.