Bell & Gossett S14334B Technologic 5500 Series Variable Primary Pump and Valve Controller User Manual

Page 11

11

3.1

Power-up

Put LOCAL-REMOTE-OFF (LRO) switch in the

LOCAL position. Put the optional AUTO-OFF-HAND

switch in the AUTO position.

Turn main disconnect on.

3.2

Technologic Pump Controller Screen

Upon powering up the controller, the display will light

and show the Technologic Variable Primary Pump

and Valve Controller default screen shown below:

Technologic Pump

Controller

MM/DD/YY HH:MM:SS A/P

Normal Manual

The current date and time will be displayed on the

third line.

3.3

Key Functionality

The names of the keys on the Operator Interface

Panel (OIP) are shown as CAPITAL LETTERS in this

manual. Table 1 shows the functionality of the keys

on the OIP.

3.4

LEDs

The START-STOP LED will be flashing. If the START-

STOP LED is not illuminated as described above,

press the START-STOP button once to light the LED.

The Auto-Manual LED should be green for auto oper-

ation. The display should also indicate MANUAL in

the lower right hand corner. If not, press the AUTO-

HAND key to enter the operation mode menu, press

the SET POINT/2 key, then the ENTER key to select

manual operation.

The PREV. SCREEN and NEXT SCREEN LEDs flash

when the keys can be used to navigate to neighbor-

ing screens.

The HELP LED flashes when HELP can be pressed to

obtain information.

Section 3 - Operator Interface

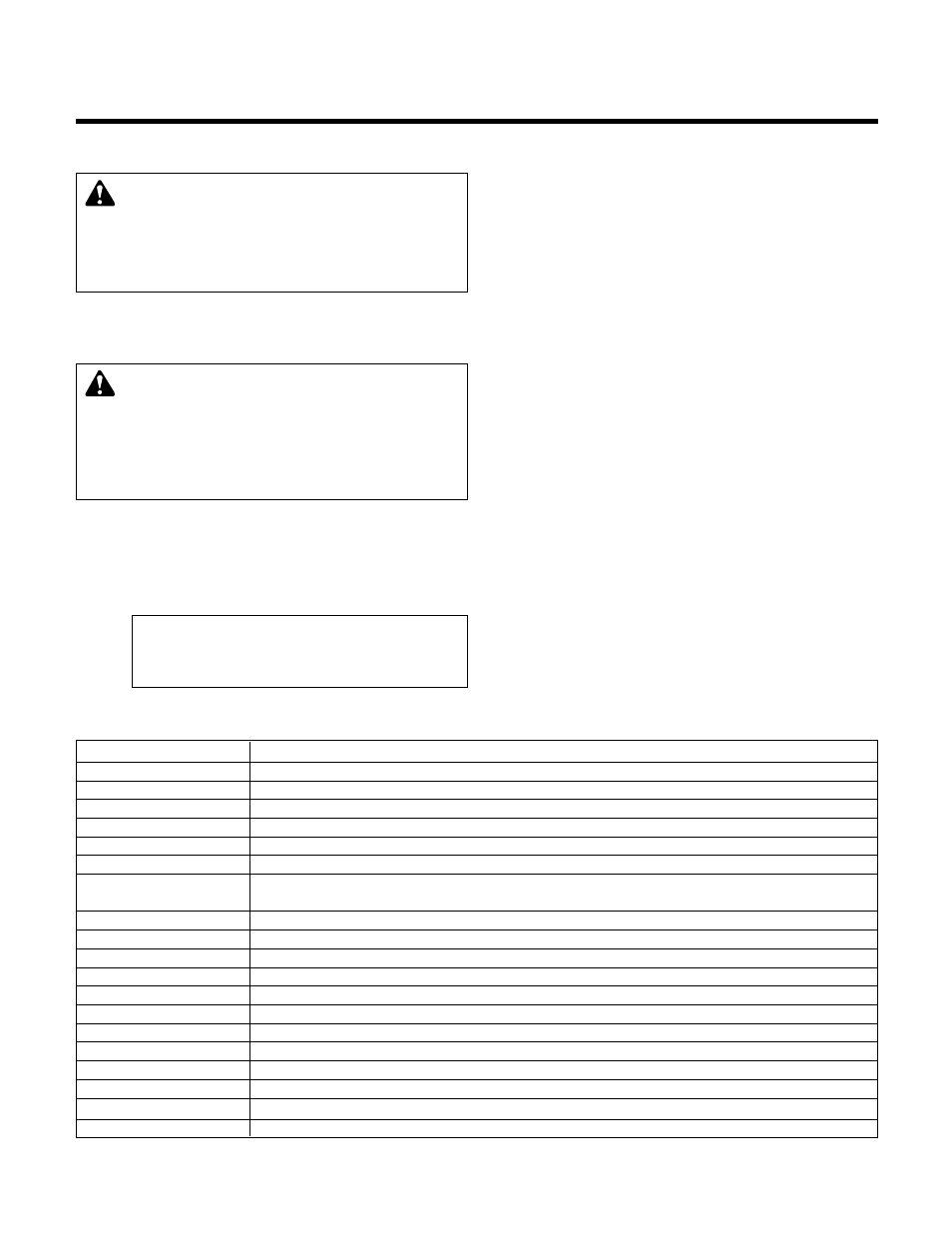

Key Name

Functionality

Start/Stop

Starts and Stops System

Reset

Resets System

Auto/Manual

Brings up the Operation Mode screen shown in section 5.5

Pump 1-6 On/Off

Turns the corresponding Pump on or off

PREV. SCREEN

navigates to neighboring screens if its green led is flashing

NEXT SCREEN

navigates to neighboring screens if its green led is flashing

HELP

gives details on alarm conditions (see section 5.11) / if used in conjunction with a function key it

will give a detailed explanation of the function key application

PROCESS VARIABLE/1

Brings up the Process Variable screen, shown in section 5.9, or used as a numeric key

SET POINT/2

Brings up the Set Point screen, shown in section 5.8, or used as a numeric key

SETUP/3

Brings up the Setup screen, shown in section 4, or used as a numeric key

ALTERNATION/4

Brings up the Alternation screen, shown in section 5.10, or used as a numeric key

F1/LOG/5

Brings up the Log Menu, shown in section 6.13, or used as a numeric key

F2/6

Used as a numeric key or an up arrow for manual control of pumps or bypass valve

YES/7

Used as a numeric key or YES

F3/INFO/8

Shows controller information screen, shown in section 6.12, or used as a numeric key

F4/9

Used as a numeric key or a down arrow for manual control of pumps or bypass valve

NO/0

Used as a numeric key or NO

ENTER

Used to confirm entries and to advance to the next item if there are multiple entries

CLEAR

Used to clear entries and to exit some screens

Table 1: Key Functionality

WARNING:

Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices.

FAILURE TO FOLLOW THESE INSTRUC

-

TIONS COULD RESULT IN SERIOUS PERSONAL

INJURY, DEATH, AND/OR PROPERTY DAMAGE.

WARNING:

Electrical shock hazard. Multiple power

sources. The off position of the LOCAL-REMOTE-

OFF switch does not disconnect all of the power sources in

the technologic panel. All power sources must be discon-

nected prior to entering the control panel.

FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY, DEATH, AND/OR PROP-

ERTY DAMAGE.