Proportional, integral, and derivative, Pulse, width, modulation), Control – YSI 5500D-1 User Manual

Page 72

YSI 5X00

143

YSI 5X00

142

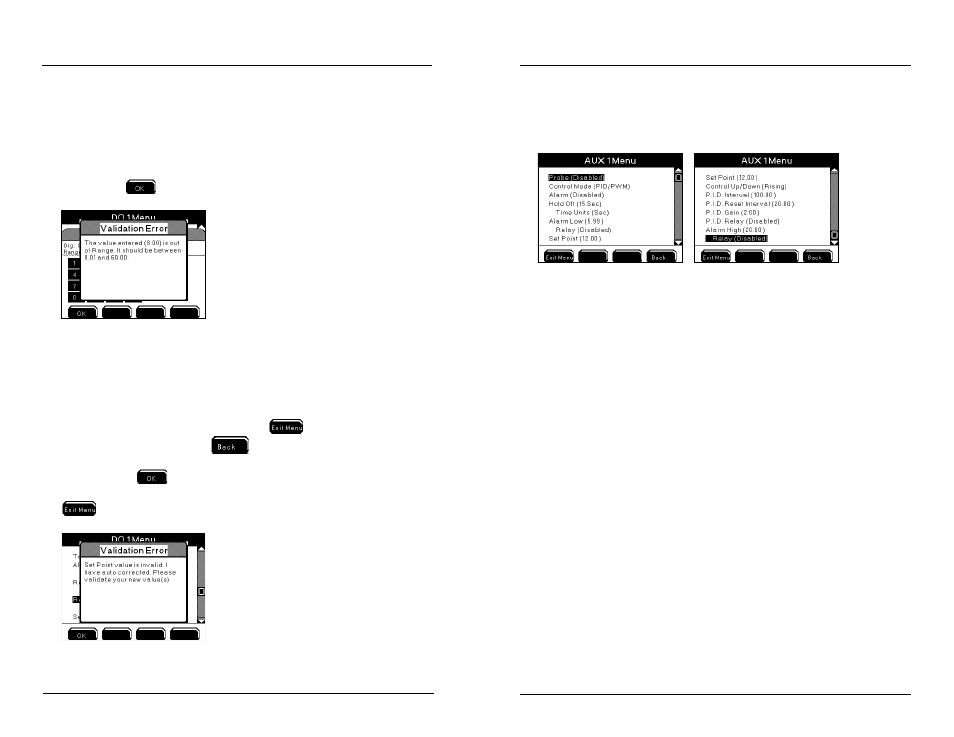

Example - entering “63” for DO set point results in validation error because the

valid range for the DO sensor system is 0.00 to 60.0 mg/l. User must configure

value within valid range. In addition, the value cannot breach respective control

and alarm system values.

Example - configuring set point value of 8.00 mg/L with range low value of 8.00

mg/l results in validation error. Valid set point range is displayed at validation error

display. Press

to return to numeric keypad to enter valid value.

Autofix occurs when a high or low control value is entered that breaches the set point

value. Autofix changes the high or low control value by one least significant digit

away from the set point value. The set point value is never adjusted.

Example - Entering 8.00 mg/L as the range low value when the set point value is

8.00 mg/L results in an auto fix of the control value. The invalid control value is

displayed at the sensor setup menu. Pressing

is not an option after saving

a value at numeric keypad. Press

from the sensor setup menu to continue

with the autofix. A validation error window is displayed to show that the autofix has

occurred. Press

to return to sensor setup menu. Verify that the autofixed

values are configured for user’s specific application and reconfigure as needed. Press

to save configuration and return to Run Screen.

PID

(Proportional, Integral, and Derivative

)

/

PWM

(Pulse, Width, Modulation)

Control

PID/PWM control menu options are shown below for an aux analog system.

PID/PWM Control uses a complex algothrium in determining the best way to sustain

water system value(s) around a set point. PID/PWM control is a feed back control

system. Three factors determine how PID/PWM control seeks to maintain water

system value(s) around a set point. The three factors are:

-the error (distance) from present measurement of input to set point (present time);:

-the duration of the error (accumulation of past errors)

-the speed at which the value is approaching the set point (predicts future errors) ;

The PID/PWM control system is considered active whenever error exists away from

the configured set point. (See PID/PWM up/down control configuration -page 144)

The PID/PWM control system is flexible and can be tuned to keep water systems

around their set points even though the environment is exposed to disturbances

that drive the input value away from set point. An example of a PID/PWM control

system that most readers will be familiar with is a cruise control system in a car. Ac-

celeration and deacceleration adjustments are continually being made to maintain

the car at a constant speed or set point.

Configure PID/PDW control systems at Sensor Setup menus.

PID/PWM control also allows configuration of high and low alarm systems to

activate peripheral devices and/or to provide alarm notification messages when

alarm condition(s) exist.

Notes:

- Changing control method between PID/PWM and Set Point may result in

invalid setp point, control and alarm value configurations. Always reconfirm

sensor setup system menu configuration when control mode is changed.

- PID/PWM control is not available for aux digital systems.

- DO system(s) PID/PWM set point can be configured using either mg/L or

%Sat set point.

Configuring the 5X00

Configuring the 5X00