2 special information on profibus dp, 2special information on profibus dp – VEGA VEGACOM 557 Profibus DP User Manual

Page 77

VEGACOM 557 Profibus DP

77

Supplement C

2

Special information on

Profibus DP

Profibus DP is designed for quick data ex-

change on the sensor/actuator level. Here,

central control instruments (such as e.g.

PLC) communicate via a quick, serial con-

nection with decentralised input and output

instruments. The data exchange with these

decentralised instruments is mainly done on

a cyclical basis. The central control (Master)

reads the input information of the Slaves and

writes the output information to the Slaves.

Thereby the bus cycle time must be shorter

than the programming cycle time of the cen-

tral control, which in many applications is

approx. 10 ms.

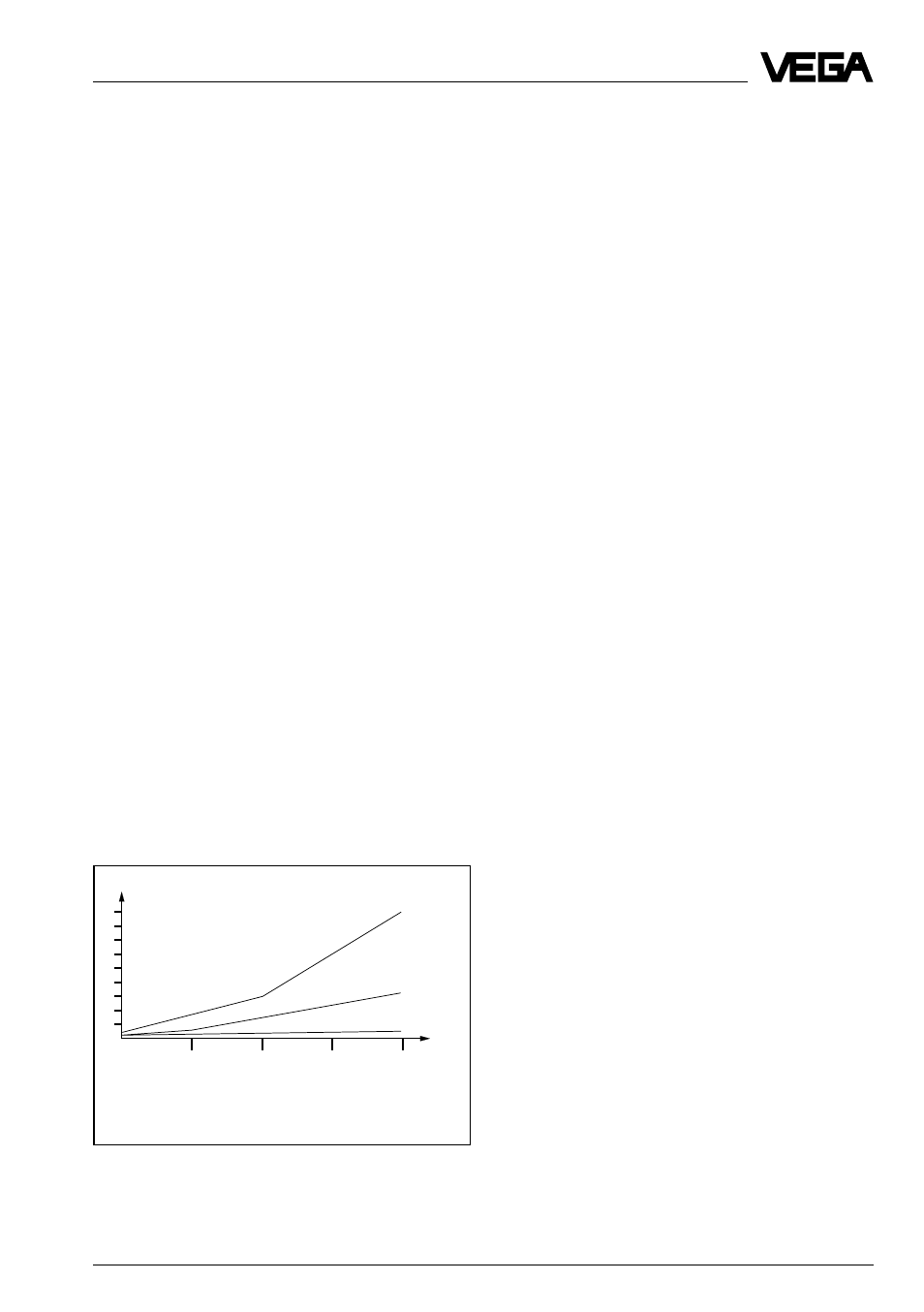

The following diagram shows the transmis-

sion time of Profibus DP in relation to the

number of participants and the transmission

speed.

The considerable speed increase, compared

to the Profibus FMS, is particularly due to the

fact that the transmission of the input and

output data is carried out in a message cycle

by using the SRD service (Send and Receive

Data Service) of layer 2. Furthermore, the

transmission speed has been increased up

to 12 Mbit/s and minimum requirements on

the efficiency of the protocol implementation

have been set.

Diagnostic functions

The comprehensive diagnostic functions of

Profibus DP enable quick error localisation.

The diagnostic messages are transmitted via

the bus and evaluated in the Master . They

are divided into three levels:

Station-related diagnostic

Message about general operating condition

of a participant, e.g. excess temperature or

low voltage.

Module-related diagnostic

These messages indicate that within a certain

E/A subrange (e.g. 8 Bit output module) of a

participant, a diagnostic is due.

Channel-related diagnostic

Here, the reason for the error relating to an

individual input/output Bit (channel) is stated,

such as e.g. short circuit of output 7.

System configuration and instrument

types

With Pr ofibus DP,

mono or multimaster

systems are possible. A high degree of flex-

ibility for system configuration is thereby

ensured. Max. 126 instruments (Master or

Slaves) can be connected to one bus. The

bus structure enables non-reactive coupling

and decoupling of stations or step-by-step

setup of the system. Later extensions do not

influence the stations which are already in

operation.

On

monomaster systems,

only one Master

is active on the bus during the operating

phase of the bus system. In figure 5, the

system configuration of a monomaster sys-

tem is shown. The PLC control is the central

control component.

In

multimaster operation,

there are several

Masters on one bus. They either form inde-

pendent subsystems, each consisting of a

DPM1 and the respective DP slaves, or addi-

tional planning and diagnostic instruments.

Bus cycle time of a Profibus DP Mono-Master system

Frame conditions: Each Slave consists of 2 Byte input and 2

Byte output data. The min. Slave interval time is 200 micro

seconds. Tsdi = 37 bit times, T sdr = 11 bit times

2

6

10

14

18

5

10

20

30

Bus cycle

time [ms]

500 kbit/s

1.5 Mbit/s

12 Mbit/s

DP-Slaves