Trouble shooting – M&C TechGroup CSS-V2 Operator's manual User Manual

Page 26

26

Gas sampling and gas conditioning technology

4-1.2-ME

17

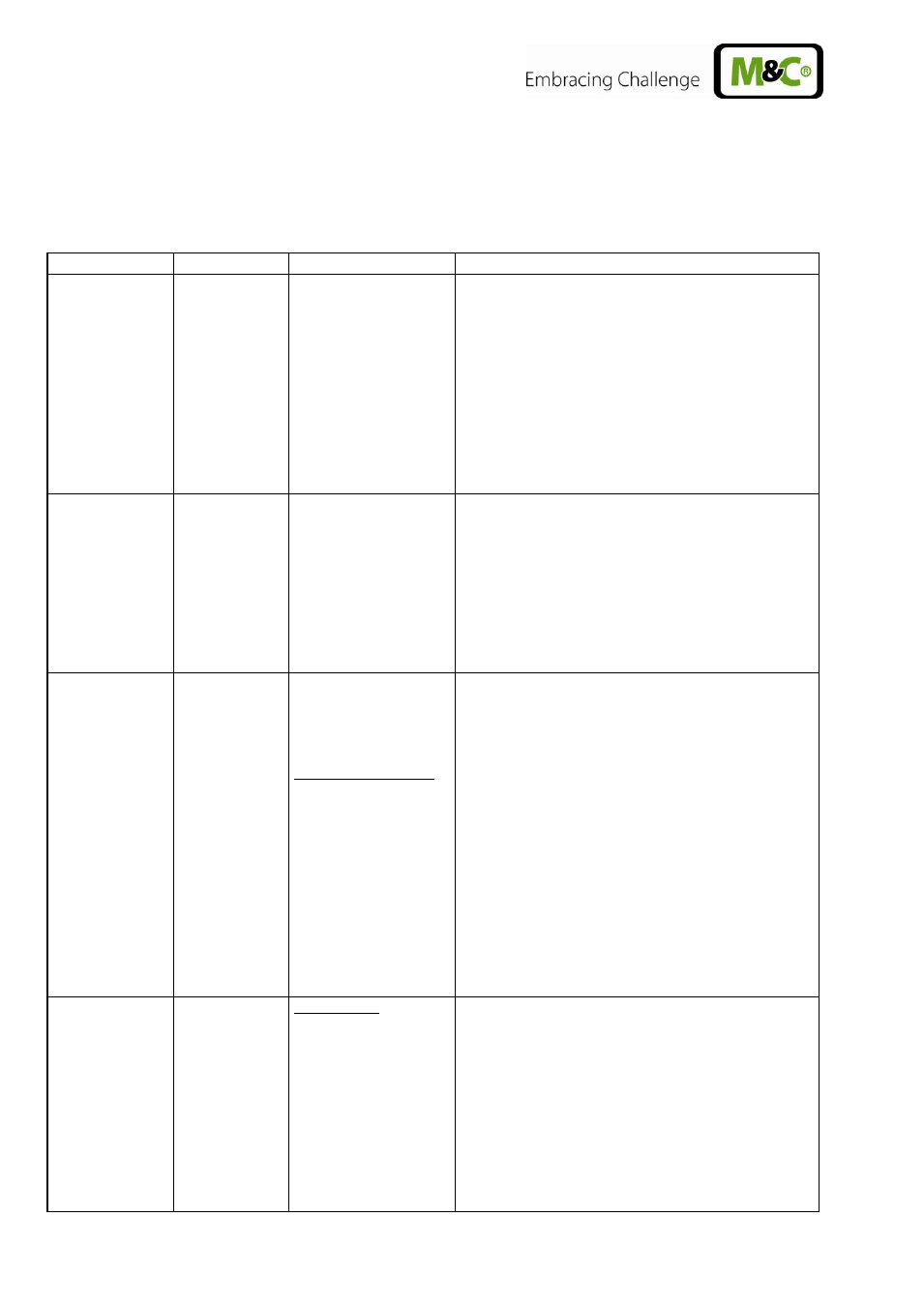

TROUBLE SHOOTING

The following table shows possible sources of errors and how to remove them (not applicable for the

starting-up phase).

Display

Fault

Possible cause

Examination/Correction

None

No supply voltage;

Check the supply voltage according to the type

plate;

ok?

Control whether the mains plug is put in correctly;

ok?

Examine the fine fuses F1, F2 in the cold appliance

socket;

ok?

LED K1 is

beaming

permanently

and temp. > 8°C

Cooler alarm „Excess

temperature“; cooler

switches off the

sample gas pump

automatically if

existing;

Ventilator does not

function

Ambient temperature too high;

ok?

Free convection inside the gas conditioning unit

upset internal temperature too high;

ok?

Sample flow or dew point too high? Reduce flow.

ok?

Return the instrument for repair to M&C.

Temp.

>2°C and

< 7,5°C

Cooler runs,

sample flow is

interrupted;

Pump

defective

Diaphragm pump

does not work;

Liquid alarm sensor:

Sensor turns sample

gas pump

automatically off;

LED Liquid alarm is beaming red.

Liquid in the filter (Dry filter and liquid alarm sensor

and check peristaltic pump, see below.)

ok?

Check the hoses for condensate draining;

ok?

Check pump hose (see 15.3.1);

ok?

Check pump SR25.2 (see 15.3);

ok?

Return instrument for repair to M&C.

Pump works,

but sample

gas flow is

interrupted;

Flow meter :

Needle valve is shut.

Sample probe or

sample hose clogged

or line squeezed;

Set the desired flow rate on the needle valve.

Loosen the sample hose from the sample gas inlet

of the gas conditioning unit (see 12.1);

Gas flow?

Clean the clogged line or replace it;