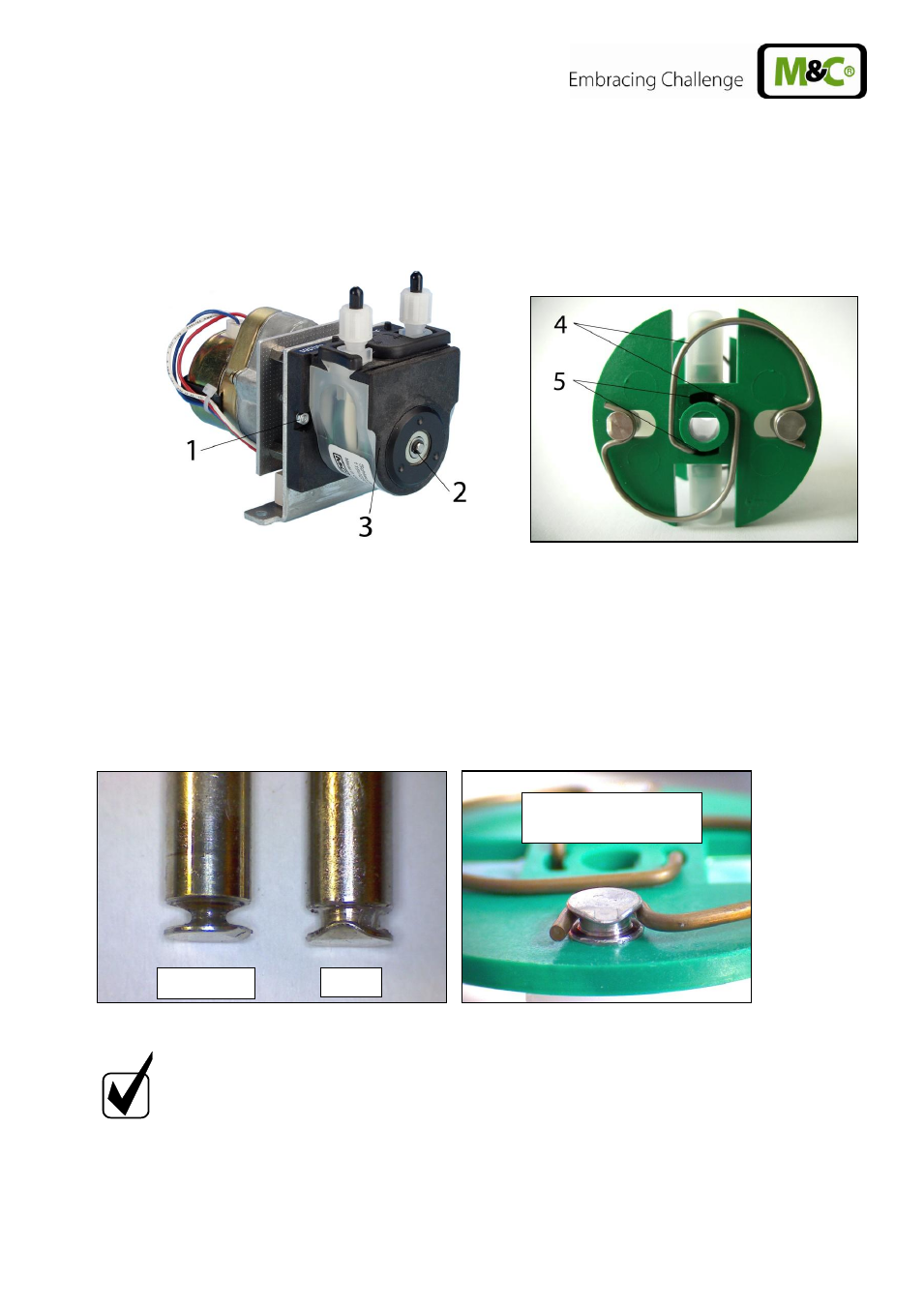

Figure 10, Disassembly of pump head and driver, Figure 11 – M&C TechGroup CSS-V2 Operator's manual User Manual

Page 23: Check of axes and rolls

4-1.2-ME

Gas sampling and gas conditioning technology

23

15.3.2 CHANGE OF CONTACT PULLEYS AND SPRINGS

Switch off the mains;

Unscrew nuts of the pump head (wrench size 5,5) and remove snap ring from motor

shaft;

Figure 10

Disassembly of pump head and driver

Draw the pump head out of the motor shaft

Take driver out of the pump head

The removal of the springs (4 pcs.) away from the driver is easily possible without the aid of

any tools. For this take spring out of the groove near to the shaft bore.

Dismount roller axes and change contact pulleys. Take care that axes are not worn out by the

springs and have damaged the dent at the axes front end. In case of abrasion the axes have to

be changed (see Figure 11).

Figure 11

Check of axes and rolls

N O T E !

The springs may occur in different coulerings. This does not constitute a

quality defect. But make sure that the right spring strength is used. This

can be identified by the spring wire diameter.

The „standard version for

Novoprene pump hoses

“ (part no. 90P1010) has a diameter of 1,1mm and

the strengthened version for FPM-, Acidflex- or Masterflex-hoses

“ (part

no. 90P1015) has a diameter of 1,2mm.

The dent prevents

rotation of the axis

new

worn out