Technical data – M&C TechGroup CSS-V2 Operator's manual User Manual

Page 10

10

Gas sampling and gas conditioning technology

4-1.2-ME

8

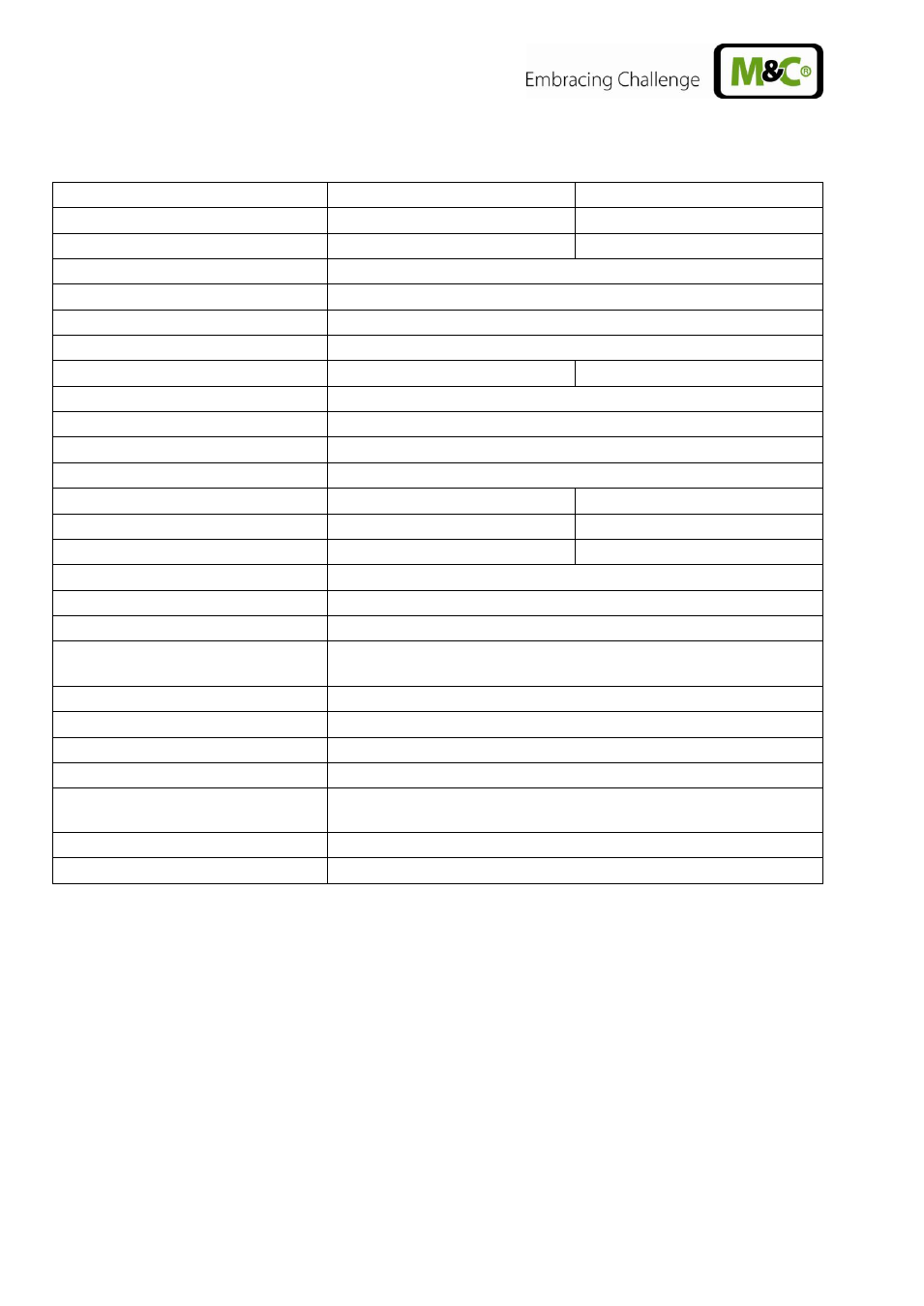

TECHNICAL DATA

Gas Conditioning Unit Type

CSS-V1

CSS-V2

Part No. 230V/50Hz

01G6010

01G6020

Part No. 115V/50-60Hz

01G6010a

01G6020a

Sample outlet dew point

Range of adjustment 2 … 7°C, factory setting +5°C

Dew point stability

at constant conditions < ±0,1 °C

Sample inlet temperature

**max. 180°C**

Gas inlet water vapour saturation

**max. +80°C

Gas flow rate

**max. 250l/h

**max. 2 x 150l/h

Ambient temperature

**+10°C to +40°C

Storage temperature

-25°C to +65°C

Pressure

0,7bar to 1,4bar abs.*

Total cooling capacity

max. 144kJ/h

Number of gas inlets

1

2

Number of gas outlets

1

2

Number of condensate outlets

1

2

Sample gas connections

Hose connection 4/6 mm

Material medium-touched parts

PVDF, PVC, Novoprene

®

, FPM, PPH, PTFE

Ready for operation

Approx. 10 min.

Mains power supply

230V 50-60Hz ± 10% or 115V 50-60Hz ± 10%

(115V/50Hz not with option sample pump)

Power consumption

max. 220VA + max: 300VA for the sample gas pumps

Fuse protection

4A, time-lag, 5x20mm

Electrical mains supply

Cold appliance plug with 2m cable

Case protection

IP20

(EN 60529)

Housing version

Sheet steel case foe 19”- or wall mounting, lacquered

RAL 7035

Case dimensions (H x W x D)

267,5mm x 483mm x 301,5mm

Weight

Approx. 22kg

PVDF = Polyvinylidenefluoride

PVC = Polyvinyl chloride

FPM = Fluor caoutchouc

PPH

= Polypropylene hard

PTFE = Polytetraflourethylene

* Standard

** Maximum values in technical data must be rated in consideration of total cooling capacity at 25°C

ambient temperature and 5°C outlet dewpoint.