4 serial communication module function list, Melsec-q – MITSUBISHI ELECTRIC QJ71C24N User Manual

Page 61

3 - 11 3 - 11

MELSEC-Q

3 SPECIFICATIONS

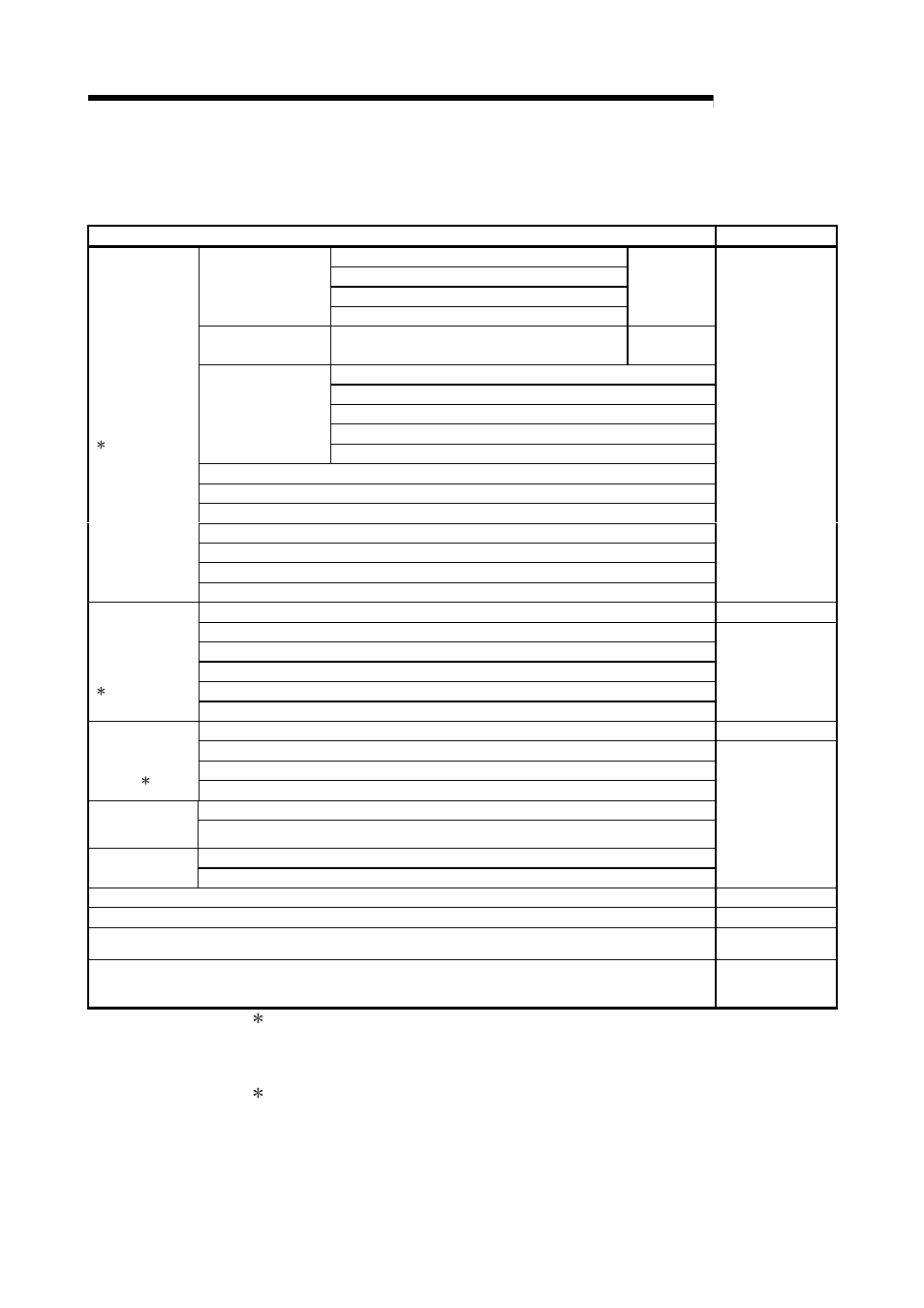

3.4 Serial Communication Module Function List

The following table lists the functions of the Q series C24.

Function

Reference section

Communication with QnA compatible 3C frame

Communication with QnA compatible 4C frame

Communication with QnA compatible 2C frame

Communication with

ASCII code

Communication with A compatible 1C frame

Formats 1 to 4

exist for each.

Communication with

binary code

Communication with QnA compatible 4C frame

Format 5

Batch read/write in bit/word units

Monitoring of device memory

Batch read/write of multiple blocks

Read/write by extension designation

Read/write of device

memory

Accessing other stations via network system

Reading/writing from/to the buffer memory of the Q series C24

Reading/writing from/to the buffer memory of intelligent function modules

Reading/writing from/to sequence program files

Monitoring the PLC CPUs (PLC CPU monitoring function)

Status control of the PLC CPUs (remote RUN/STOP, etc.)

Turning on/off input signals of the Q series C24 from an external device (global function)

Communication

using MC protocol

(

1)

Data transmission from a PLC CPU to an external device (on-demand function)

Chapter 5

Reference Manual

Data transmission/reception in any format

Chapter 6

Data transmission/reception using user frames

Data reception by interrupt programs

Monitoring the PLC CPUs (PLC CPU monitoring function)

ASCII data transmission/reception by ASCII-BIN conversion

Communication

using non

procedure protocol

(

2)

Data transmission/reception by specifying transparent code

User's Manual

(Application)

Data transmission/reception in any format

Chapter 7

Data reception by interrupt programs

ASCII data transmission/reception by ASCII-BIN conversion

Communication

using bidirectional

protocol (

1)

Data transmission/reception by specifying transparent code

Communication with MC Protocol/non procedure protocol/bidirectional protocol

Communication via

public network, etc.

(modem function)

PLC access from GX Developer

DC code control (including Xon/Xoff control)

Transmission

control

DTR/DSR (ER/DR) control

User's Manual

(Application)

Independent/linked operation of each interface

Section 4.5.2

Monitoring/testing of initial settings and setting values with utility software

Chapter 8

Supporting multiple CPU system

Section 2.10 of

Reference Manual

Remote password check

Section 3.3.3 of

User's Manual

(Application)

1 If the external device is capable of incorporating a program and communicating

data using a protocol of the MELSEC PLC, it is possible to access the PLC CPU

using the above mentioned MC protocol. Furthermore, it is possible to transfer any

data using the bidirectional protocol.

2 When it is necessary to communicate using the protocol of an external device,

such as a measuring instrument or a bar code reader, the above-mentioned non

procedure protocol is used for data communication. In that case, the processing of

the communication data becomes easier by using the user frame communication

function.