LINK Systems OmniLink II Press Automation Control User Manual

Page 54

August 30, 2002 Manual Version 1.0

4.5

4. Configuring the Operator Terminal serial ports for any software options, such as serial feed interface

and PLC Interface used.

5. Choosing whether certain bypass or reset actions for both standard and optional features are

unrestricted, or whether these actions can only be done by persons you have chosen to do so in the

security settings of the system.

6. Setting up the key/code access security system of the OmniLink to restrict certain reset or bypass

actions and settings in programming menus to specific personnel or by Program/Run key.

7. Entering any diagnostic Messages that may be sent to the Operator Terminal parallel port by outputs

from an auxiliary equipment PLC controller.

You must be able to stroke the machine to do certain parts of configuring the OmniLink II Press

Automation control in the Main Configuration Menu. The system has outputs that are connected to the

stop circuits of your press control that will be activated if a fault occurs. At this time you need to make

sure that any monitoring or control functions associated with optional Die Protection, PLS, and other

modules that you are using with the system will not generate a fault that you will have to repeatedly

reset each time you stroke. As shipped from the factory, any optional modules shipped with the system

are generally not programmed to perform monitoring or control actions and will not generate faults.

However, if anyone at your facility has experimented with programming various monitoring functions

before the system is configured, you may have to reprogram them to prevent faults when you stroke as

follows: make sure all counters are turned off; if Die Protection or Analog Process Monitor options are

provided, set all channels to Unused; if Tonnage and Signature Monitor option is provided, press the

BYPASS softkey to bypass both high and low limits.

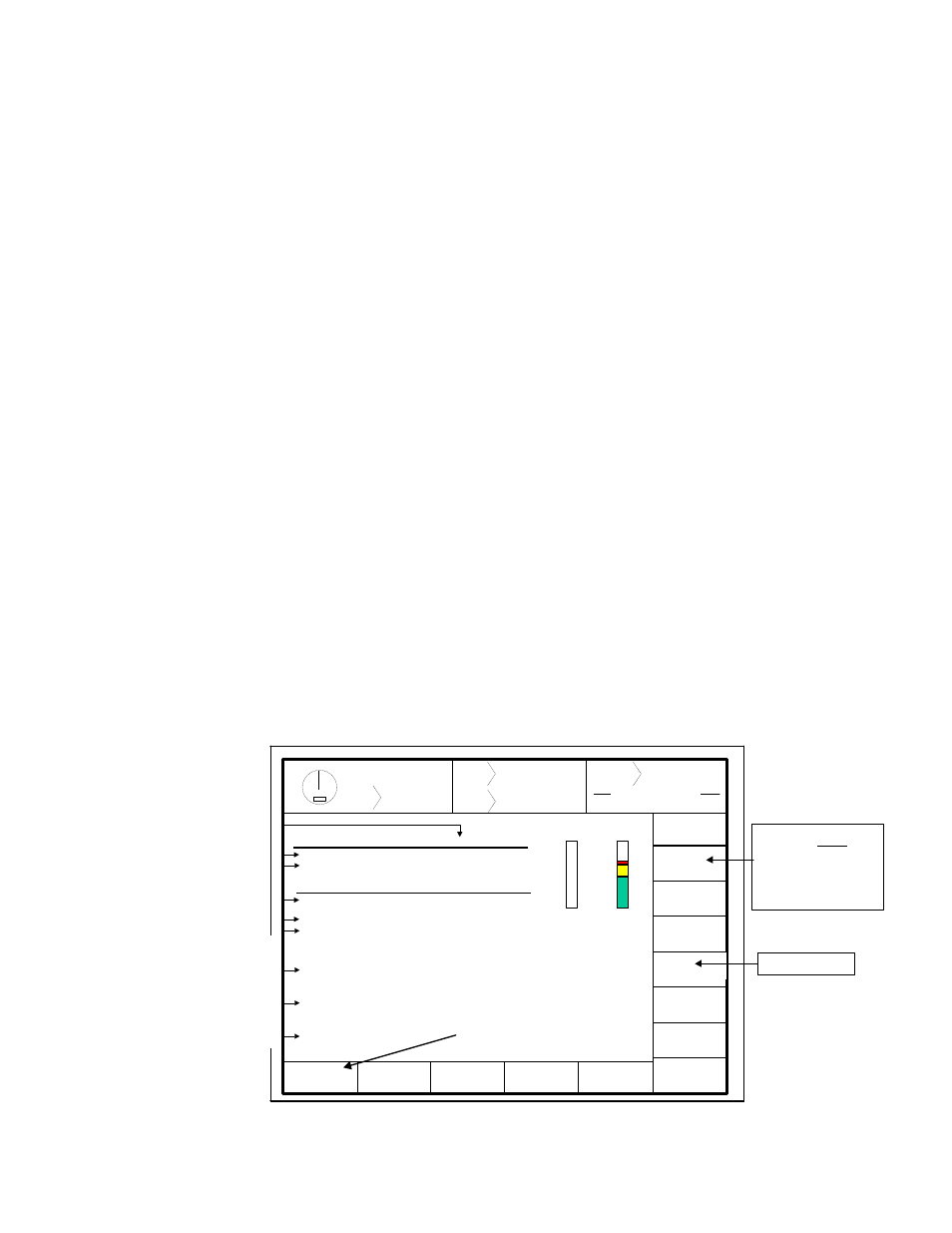

The Main Configuration Menu is accessed from the Brake Monitor menu. The CONFIGURE softkey is

available only in the Brake Monitor Menu when the Program/Run switch is in the PROG position. The

Brake Monitor menu is shown in Figure 4.4 with Program/Run switch in PROG position.

Figure 4.4 Brake Monitor Menu

Stroke

Mode Single Stroke

Drive

Speed

Stroke

Speed

SPM

SPM

0

0

Order

Counter

PC STATUS

Counter OFF

PRESS

CONTROL

CHANGE

NUMBER

MOTOR

SPEED

TONNAGE

MONITOR

AUTO

SETS

DIE

PROTECTION

EXIT

0

0

SPM

0

% LOAD

161

READY TO STROKE

TOP

AUXILIARY

COMM.

DIAGNOS

OPERATOR

STATON

Brake Monitor

Limit

Stoptime

Top Stroke Stop

0200

183

mSec

Mid Stroke Stop

0250

0

mSec

Clutch time

0275

0250

mSec

Limit

Actual

Auto Single Stroke Time ……… 5

Sec

Feed Complete Position ……… 25

Degs

Cont. on Demand Time ………. 10

Mins

Auxiliary Equipment Message

Option is not Installed

Reason for the Last Stop

Power Up

Present Running Status

Ready to Stroke

1

2

10

5

6

7

4

8

9

3

SYSTEM STATUS

Brake

Monitor

RESET

ERROR

OK

Die Protection Stop

Critical Angle: 145

Stopping Degrees: 57

AUTO

SETS

TONNAGE

MONITOR

DIE

PROTECTION

ANALOG

PROC MON

AUXILIARY

COMM.

SUPPLY

ACCESS

CODE

The SUPPLY ACCESS CODE

Softkey legend will not be

present if key only access

mode is chosen in the

configuration menu. This

area will be blank in Run and

will have CHANGE NUMBER

in Program.

7

8

9

SPEED

ADJUST

CONFIGURE

DIAGNOS

RESET

FAULT

Appears Only When

Fault Exists

APPEARS ONLY IN PROGRAM

OK