Press crown, Omnilink ii lcd, Omnilink ii press automation control – LINK Systems OmniLink II Press Automation Control User Manual

Page 14

August 30, 2002 Manual Version 1.0

2.5

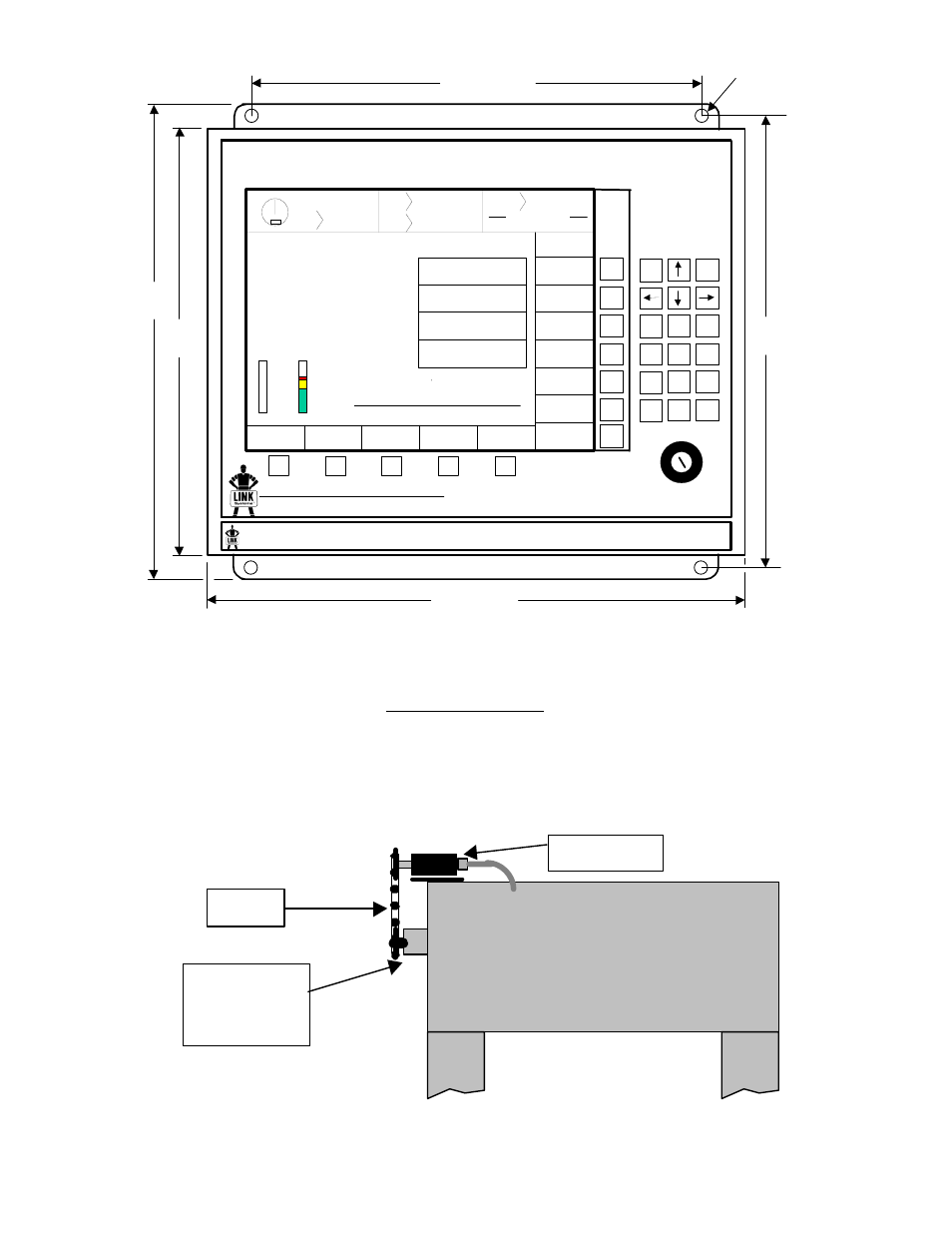

Figure 2.5 Dimensions for Mounting OmniLink II LCD Operator Terminal

Section 2.2.2 Mounting the Resolver

Mounting the resolver to be driven in a one to one ratio by the crank or eccentric shaft. The resolver

may be direct driven by a coupling off the center of the shaft or driven by a chain and sprockets as

shown in Figure 2.6.

Figure 2.6 Mounting the 2500 or 5000 Resolver

Strok e

Mode

Driv e

Speed

Strok e

Speed

SP M

SP M

0

0

Order

C ount er

SYS TEM STATUS

Counter OFF

MAIN

S CREEN

PRESS

CONTROL

AUTO

S ETS

TONNAGE

MON ITOR

DIE

PROTEC TION

LIMIT

SWITCH

JOB

SETUPS

0

0

MOTOR

SPEED

S TATUS:

OK

S TATUS:

ALL CON DITI ONS OKAY

S TATUS:

ALL CON DITI ONS OKAY

S TATUS:

ALL CON DITI ONS OKAY

JOB NUMBER DE SCRIP TION

100000 FRONT BRACKET

COUN TER LIMIT QUANTI TY STATE

ORDER

BATCH

SPM

0

% LOAD

161

2000

500

7

7

ON

ON

READY TO STROKE

T OP

C OUNTERS

CHG

ACC

CLR

ENT

1

2

3

4

5

6

7

8

9

0

BRAKE

MO NITOR

ON

OmniLink II LCD

OPERATOR TERMINAL

LIN K ELECTRIC & SAFETY C ONTROL CO.

444 McN ALLY DR. NASHVILLE, TN 37211

PHONE (615) 833-4168

OK

PROG RUN

11.125

(28.26)

11.00 ( 27.74)

OmniLink II Press Automation Control

13.50 (34.29)

11.65

(29.59)

10.4

(26.42)

0.312 (.792)

Diameter

(4 Places)

Enclosure Depth: 6 (15.24)

PRESS

CROWN

RESOLVER

CRANK OR

ECCENTRIC

SHAFT

CHAIN

NOTE! A CHAIN GUARD

IS NECESSARY TO MEET

OSHA 1910.219 STANDARDS