LINK Systems OmniLink II Press Automation Control User Manual

Page 108

August 30, 2002 Manual Version 1.0

6.3

PARAMETER SPECIFICATION

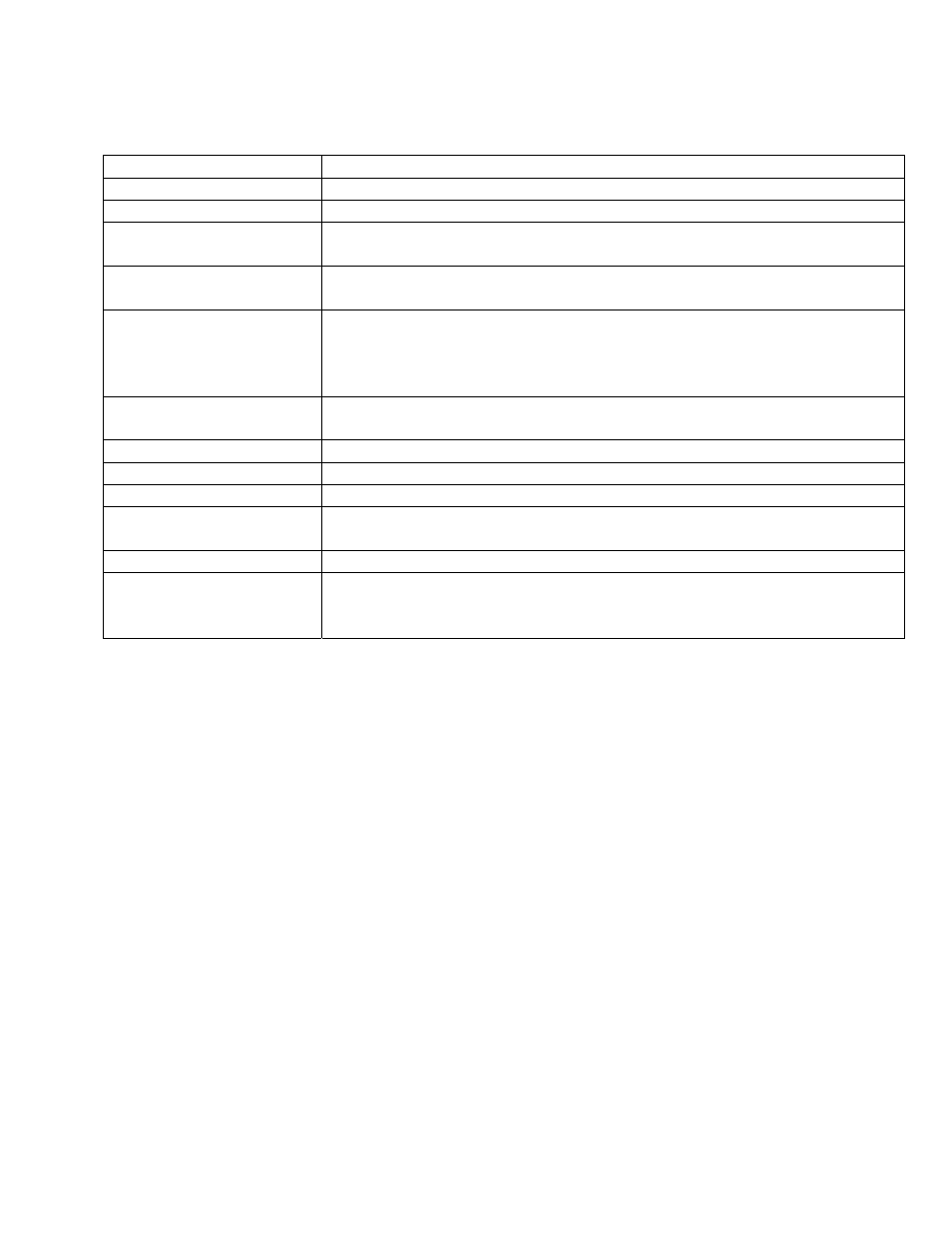

Enclosure Dimensions

11.9” (302 mm) High x 6.25” (159 mm) Wide x 4” (102 mm) Deep

Mounting Footprint

11.15” (283 mm) High x 4.25” (108 mm) Wide

Maximum Overall

Clearance Dimensions

17” (432 mm) High x 6.25” (159 mm) Wide x 8” (203 mm) Deep

Input Power

100 to 135 VAC @ .5 Amps (Voltage Selector in 115 position) or

200 to 270 VAC @ .25 Amps(Voltage Selector in 230 position)

Input Fuse Type

95 to 140 VAC operation Littlefuse 313.500, Bussman MDL-1/2, Gould

GLD-1/2 or equivalent

190 to 280 VAC operation Littlefuse 313.250, Bussman MDL-1/4, Gould

GLD-1/4 or equivalent

Sensor Types

3 Wire DC, NPN or PNP

with no LED in parallel with the load

Available Sensor Power

24 VDC @ 1 Amp maximum (total for all sensors)

Sensor Voltage Drop

4 VDC maximum across switch in ON (closed) state

Sensor Leakage Current

500 uA maximum in OFF (non-conducting) state

Front Panel Micro-

Connector (optional)

Mating Connectors Link Part # 108046 Connector Straight

Link Part # 108048 Connector Right Angle

Binding Post (optional)

Mating Connector Link Part # 100377 – White Banana Plug

Quick Die Change

Receptacle (optional)

Mating Cordset Link Part # 108776 – 2 Meter Length

Link Part # 108777 – 3 Meter Length

Link Part # 108778 – 5 Meter Length

Table 6.2 Specifications

Section 6.3 Mounting

The Digital Die Protection and Process Monitor is designed to be mounted in close proximity to the

tooling. The unit should be mounted in a location that allows the front panel indicators to be viewed and

easy access to the front panel receptacles and to the quick die change receptacle. The enclosure

dimensions and mounting footprint are shown on Figure 6.1. The unit shown in Figure 6.1 has both the

door mounted binding posts and micro connectors, and the bottom mounted 19 pin connector. Some

models of the Digital Die Protection and Process Monitor do not have the door mounted binding posts

and micro connectors. Some models do not have the bottom mounted 19 pin connector. The absence of

these items will decrease the mounting clearance requirements.

Normally the Digital Die Protection and Process Monitor module can be mounted directly to the press

frame. However in high shock and vibration environments, shock mounts may be required. If it is

determined that shock mounts are required, please consult Link Systems for recommendations.