LINK Systems OmniLink II Press Automation Control User Manual

Page 131

August 30, 2002 Manual Version 1.0

6.26

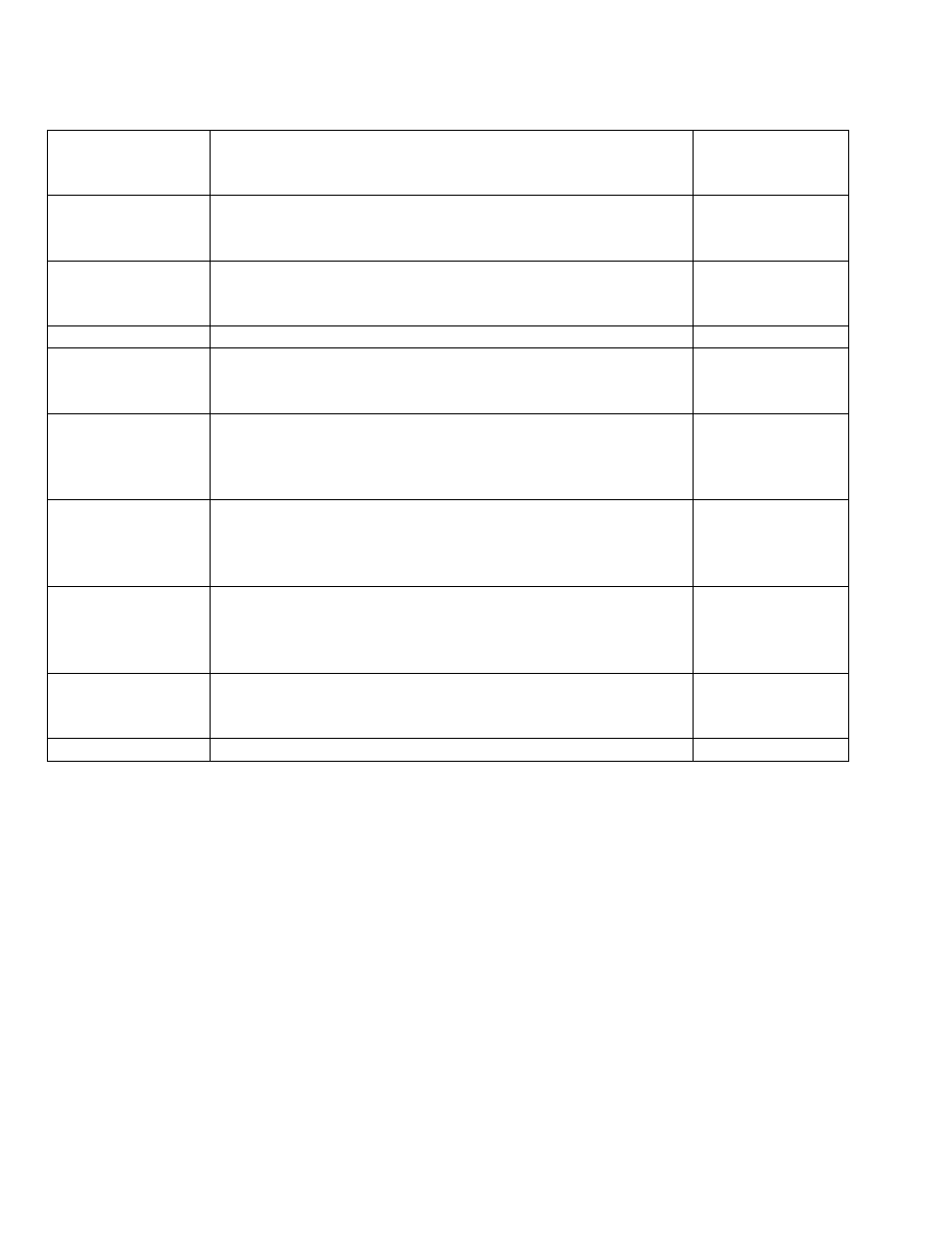

Channel Type

Description

Section for

Additional

Information

Static

Channel type used to monitor sensors that are independent of

the machine production cycle. There is no timing associated

with these inputs.

6.5.1

Cyclic

Channel type used to monitor events that occur once each

machine cycle. These events must occur during the set timing

window.

6.5.2

In Position

Channel type used to monitor material feed progression.

6.5.3

One Part Detector

Edge

Channel type used to monitor part ejection for parts that are

completely out of the die area as soon as there are sensed by

the channel’s input sensor.

6.5.4

One Part Detector

Pass

Channel type used to monitor part ejection for parts that are

not completely out of the die area when they are first sensed

by the channel’s input sensor. The part must be completely

past the sensor by the end of the timing window.

6.5.5

Two Part Detector

Edge

Channel type used to monitor two parts whose ejection is

sensed by the same sensor. The parts must enter the sensor’s

sensing field at different times. The last part does not have to

exit the sensing field at the end of the timing window.

6.5.6

Two Part Detector

Pass

Channel type used to monitor two parts whose ejection is

sensed by the same sensor. The parts must enter the sensor’s

sensing field at different times. The last part must exit the

sensing field at the end of the timing window.

6.5.7

Transfer

Channel type used to monitor part transfer. The channel’s

input sensor must report that the part is present through the

entire timing window.

6.5.8

Custom

Channel type that allows the user to define the channel logic.

6.5.9

Section 6.7.1.2 Description

Input descriptions are helpful labels which aid the operator in identifying which sensor is tied to a

particular input and what that input is monitoring. This is of particular value if many die protection

inputs are used. Since the input "Type" labels are by necessity general in nature, an input description

can be used to give more specific information to the operator. For example, suppose two separate

sensors are being used to check for two different pilot holes in the part. The die protection inputs which

these sensors are wired to would both be programmed as Cyclic type inputs to check proper operation of

the sensor (pilot hole both present and absent at different points in the stroke). In this application it

would be helpful to specify a description for each input such as "PILOT HOLE LEFT" and "PILOT

HOLE RIGHT" so that if a failure occurred the operator would know immediately which hole was not

seen. The system can have 80 names. Each name can be 20 alpha-numeric characters in length.

Moving the cursor to highlight the Description and then selecting the CHANGE NAME softkey can

access the Die Protection Names screen. There are several names that were programmed by the factory.

These are common names that may be helpful to the user. The user can edit or delete any of the factory