Press – LINK Systems OmniLink II Press Automation Control User Manual

Page 17

August 30, 2002 Manual Version 1.0

2.8

Section 2.3 Wiring System Modules and Components

Section 2.3.1 Conduit Runs

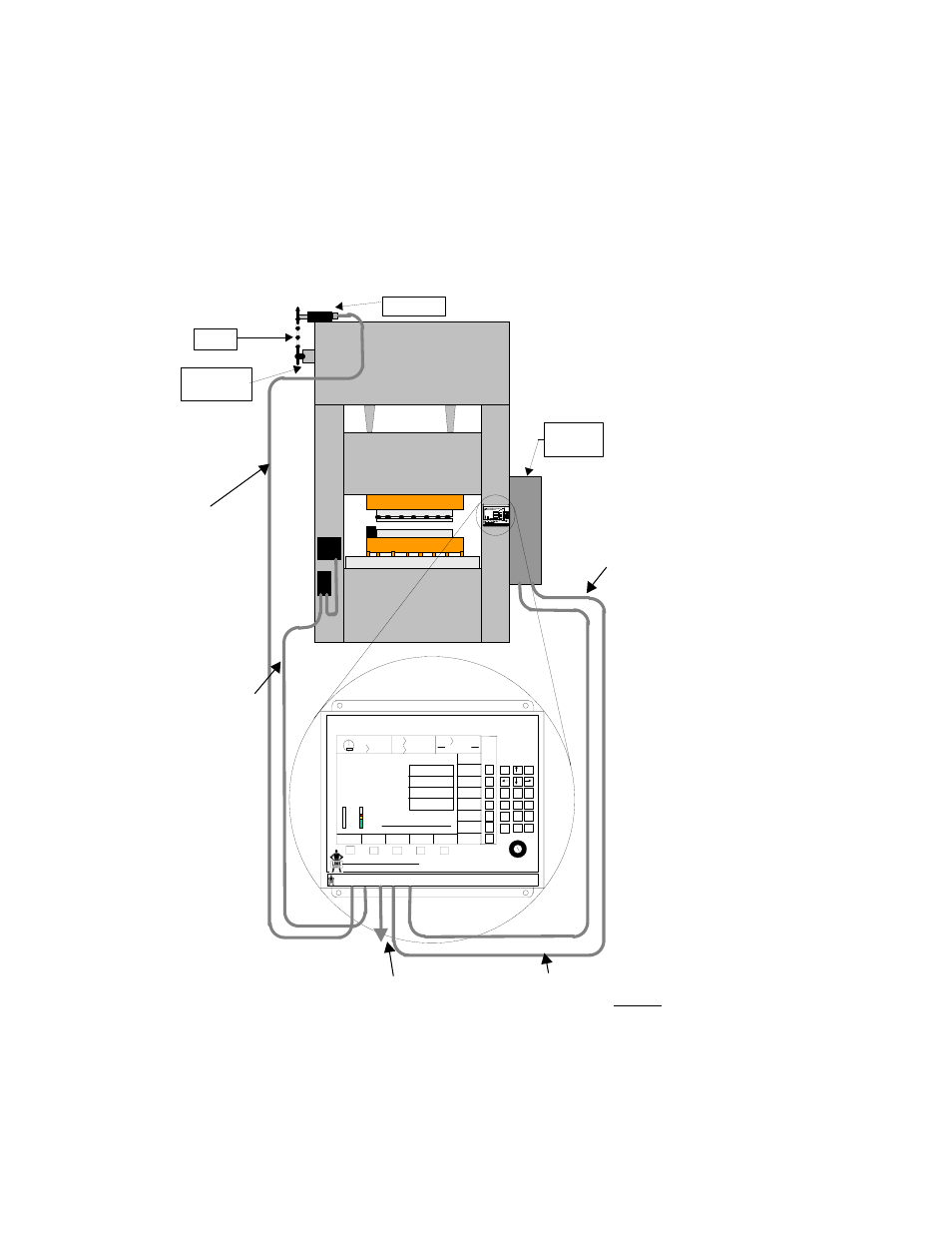

Wiring between the enclosures for OmniLink II Press Automation Control components should be run in

conduit. The use of flexible liquid tight conduit with ground is suggested, but hard conduit can also be

used. Figure 2.9 shows some of the typical conduit runs that may be required.

Figure 2.9. General View of Components and Wiring Runs for Installation.

1/2” Flexible conduit

with ground for

115VAC from press

control transformer,

connections to control

dual valve output,

stop outputs from

OmniLink to press

control

.

PRESS

S

tro

k

e

M

o

d

e

D

riv

e

S

p

e

e

d

S

tro

k

e

S

p

e

e

d

S

P

M

S

P

M

0

0

O

rd

e

r

C

o

u

n

t

e

r

S

Y

S

T

E

M

S

T

A

T

U

S

C

o

u

n

te

r O

F

F

M

A

IN

S

C

R

E

E

N

P

R

E

S

S

C

O

N

T

R

O

L

A

U

T

O

S

E

T

S

T

O

N

N

A

G

E

M

O

N

IT

O

R

D

IE

P

R

O

T

E

C

T

IO

N

L

IM

IT

S

W

IT

C

H

J

O

B

S

E

T

U

P

S

0

0

M

O

T

O

R

S

P

E

E

D

S

T

A

T

U

S

:

O

K

S

T

A

T

U

S

:

A

L

L

C

O

N

D

IT

I

O

N

S

O

K

A

Y

S

T

A

T

U

S

:

A

L

L

C

O

N

D

IT

I

O

N

S

O

K

A

Y

S

T

A

T

U

S

:

A

L

L

C

O

N

D

IT

I

O

N

S

O

K

A

Y

J

O

B

N

U

M

B

E

R

D

E

S

C

R

IP

T

IO

N

1

0

0

0

0

0

F

R

O

N

T

B

R

A

C

K

E

T

C

O

U

N

T

E

R

L

IM

IT

Q

U

A

N

T

IT

Y

S

T

A

T

E

O

R

D

E

R

B

A

T

C

H

S

P

M

0

%

L

O

A

D

1

6

1

2

0

0

0

5

0

0

7

7

O

N

O

N

R

E

A

D

Y

T

O

S

T

R

O

K

E

T

O

P

C

O

U

N

T

E

R

S

C

H

G

A

C

C

C

LR

E

N

T

1

2

3

4

5

6

7

8

9

0

B

R

A

K

E

M

O

N

IT

O

R

O

N

Omn iL i n

k I I L C

D

O

P E

R

A T O R

T

E R M IN

A

L

L

IN

K

E

L

E

C

T

R

IC

&

S

A

F

E

T

Y

C

O

N

T

R

O

L

C

O

.

4

4

4

M

c

N

A

L

L

Y

D

R

. N

A

S

H

V

IL

L

E

,

T

N

3

7

2

1

1

P

H

O

N

E

(6

1

5

) 8

3

3

-4

1

6

8

O

K

P R

O

G R

U

N

Omn

i L in k

I I P r e s

s

A u to ma tio n

C

o n t ro

l

S trok e

M ode

Driv e

S peed

S trok e

S peed

SP M

SP M

0

0

Or der

Co unter

SYSTEM ST ATUS

Counter OFF

MAIN

SCREEN

PRESS

CON TROL

AUTO

SETS

TO NNAGE

MON ITOR

DIE

P ROT EC TION

LIM IT

SW ITCH

J OB

SE TUPS

0

0

MOTOR

SPEED

S TA TUS:

OK

S TA TUS:

ALL CONDITIONS OKAY

S TA TUS:

ALL CONDITIONS OKAY

S TA TUS:

ALL CONDITIONS OKAY

J OB N UMBER DES CRIP TION

1 00 0 00 FRON T BRACKET

COU NTER L IMIT QUANTITY S TATE

ORDER

BATCH

SPM

0

% LOAD

161

2 000

500

7

7

ON

ON

REA DY TO STROKE

TOP

C OUN TERS

CH G

AC C

C LR

E N

T

1

2

3

4

5

6

7

8

9

0

BRA KE

MONIT OR

ON

OmniLink II LCD

OPE RATOR T ERMINAL

L IN K E LECTRIC & S AFET Y CONTROL CO.

4

4 4 M cNALL Y DR . NAS HVIL L E, TN

37 2 1

1

PH ONE (61 5) 8

3 3-4 1 6

8

OK

PROG RUN

OmniLink II Press Au tomation Control

PR ESS

CONTROL

RESOLVER

C RANK OR

ECCENTRIC

C HAIN

1/2’ Flexible liquid tight

conduit with ground for

2500 Resolver cable. (3/4”

for 5000 Resolver.)

1/2” Flexible liquid tight

conduit with ground for

high speed serial bus

cable and power to

OmniLink II Press

Automation Control

optional modules

1/2” Flexible liquid tight conduit

with ground if any optional low

voltage connections: setup mode

input, analog speed or motor

current signals are used.

1/2” Flexible liquid tight

conduit(s) with ground for

other OmniLink system

options