Inside of operator terminal enclosure, 5 r/d-brake monitor module, Con8 – LINK Systems OmniLink II Press Automation Control User Manual

Page 27

August 30, 2002 Manual Version 1.0

2.18

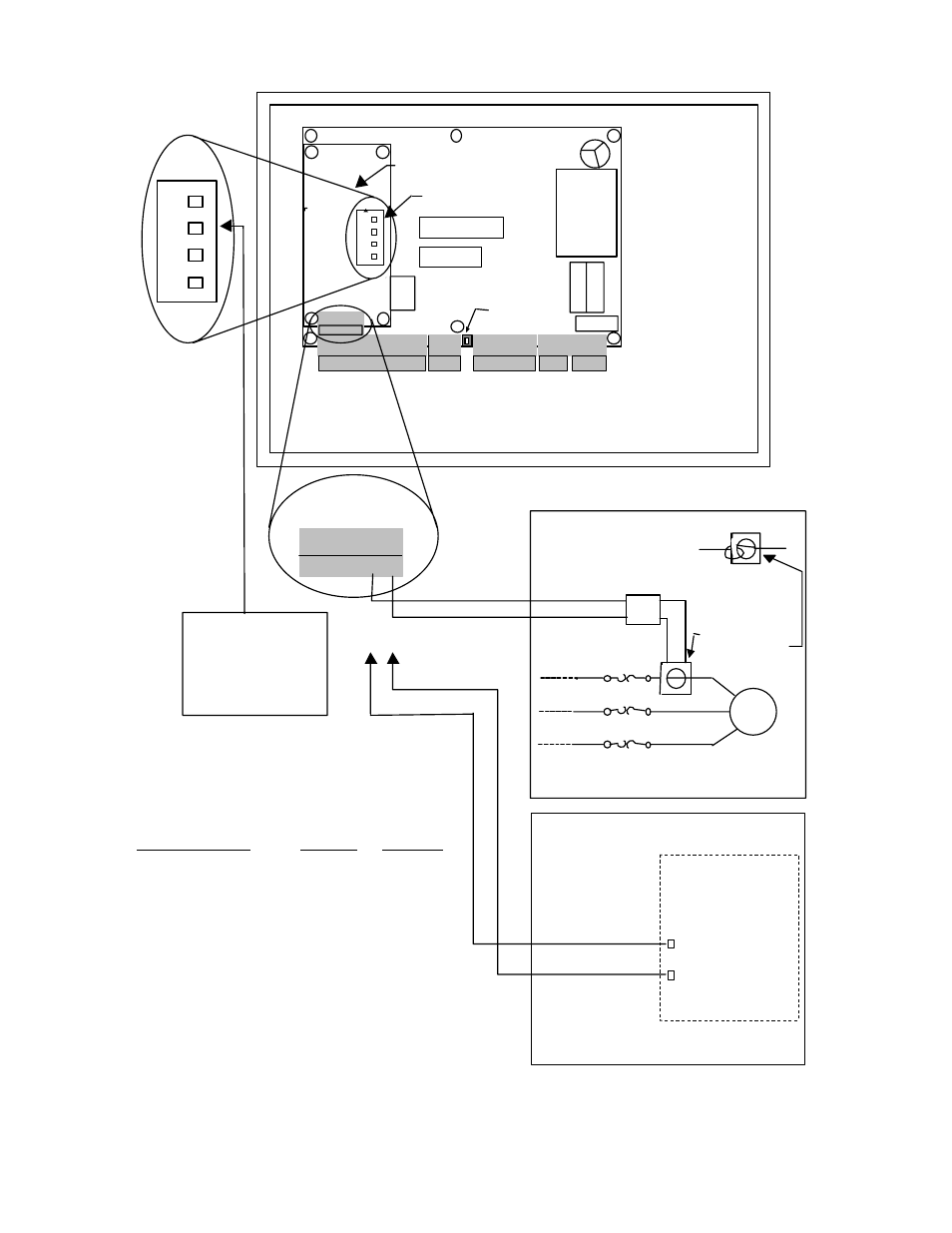

Figure 2.16 Wiring the Analog Motor Load Current Input

Transformer

Fuse

Output

Relays

Microprocessor 1

Microproc. 1

Prog. Memory

R1 2 3 4 5 6 7 8 9 10 11 12 13

CON7

SH

LD

GN

D

CA

NH

CA

NL

Can Termination

Switch

CON1

CON2

1 2 3

4 5 6 7 8 L1 L2 GND

CON5

1 2 3 4

CON4

1 2 3 4 5

CON8

R/D

IC

Analog Input/Output

802-5 R/D-Brake Monitor Module

INSIDE OF

OPERATOR

TERMINAL

ENCLOSURE

1 2 3 4 5

CON8

SP

M

IN

IS

O

G

N

D

ISO

G

N

D

SP

M

O

U

T

%L

O

A

D

1M

MAI N MOTOR

1OL

1OL

1OL

SIMPSON INSTUMENT

TRANSFORMER BUL 270-5014

CURRENT

TRANSFORMER

X:5 RATIO

1 PRIMARY TURN OR

2 PRIMARY TURNS

PRESS CONTROL

FOR FIXED SPEED OR EDDY CURRENT

DRIVE VARIABLE SPEED PRESSES

DC MOT OR DRIVE OR

AC ADJUST ABL E

F REQUENCY DRIVE

PRESS CONTROL

COMMON (REF)

ANALOG 0-1 0V OR 4-20MA

MOTOR LOAD OUTPUT

FOR DC MOTOR DRIVE OR AC ADJUST ABL E

FREQUENCY DRIVE VARIABLE SPEED P RESSES

5

4

Current Transformer

Motor HP

Motor HP

Ratio and Turns____

@220VAC

@ 440VAC

50:5 (2 Primary Turns)

2 to 3

5 to 7.5

50:5 (1 Primary Turn)

5 to 7.5

10 to 15

100:5 (1 Primary Turn)

10 to 15

20 to 30

200:5 (1 Primary Turn)

20 to 30

40 to 75

400:5 (1Primary Turn)

40 to 75

100 to 150

Current Transformer Ratios & Turns

for Various Size Motors

1

12

3

4

12

3

4

SWITCH

Board Option

OP

E

N

Throw switch 3

to closed position

for DC or AC Motor

Control with 4-20ma

Input. Otherwise leave

open.

1

2

3

4