Electronics – Labconco Type C1 Biosafety Cabinet Models 30468 User Manual

Page 35

Product Service 1-800-522-7658

35

Controlling the motor’s operation with a microprocessor adds numerous

advantages. Motor speed can be efficiently controlled across a speed range

that would damage or destroy a PSC motor. Given enough microprocessor

memory and power, the manufacturer can program in any number of user-

selected programs controlling motor speed, power and even direction of

rotation. The ultimate expression of the power of the ECM was the

development of the constant volume algorithm, by General Electric, and

used in the Axiom BSC. By testing a prototype model to a variety of airflows

and filter pressures, the motor/blower can be “characterized” for that size

cabinet. This characterization allows for the creation of a model-specific

motor-blower curve. By programming the curve values into the motor during

assembly, the motor will deliver the correct volume of air as the HEPA filters

load.

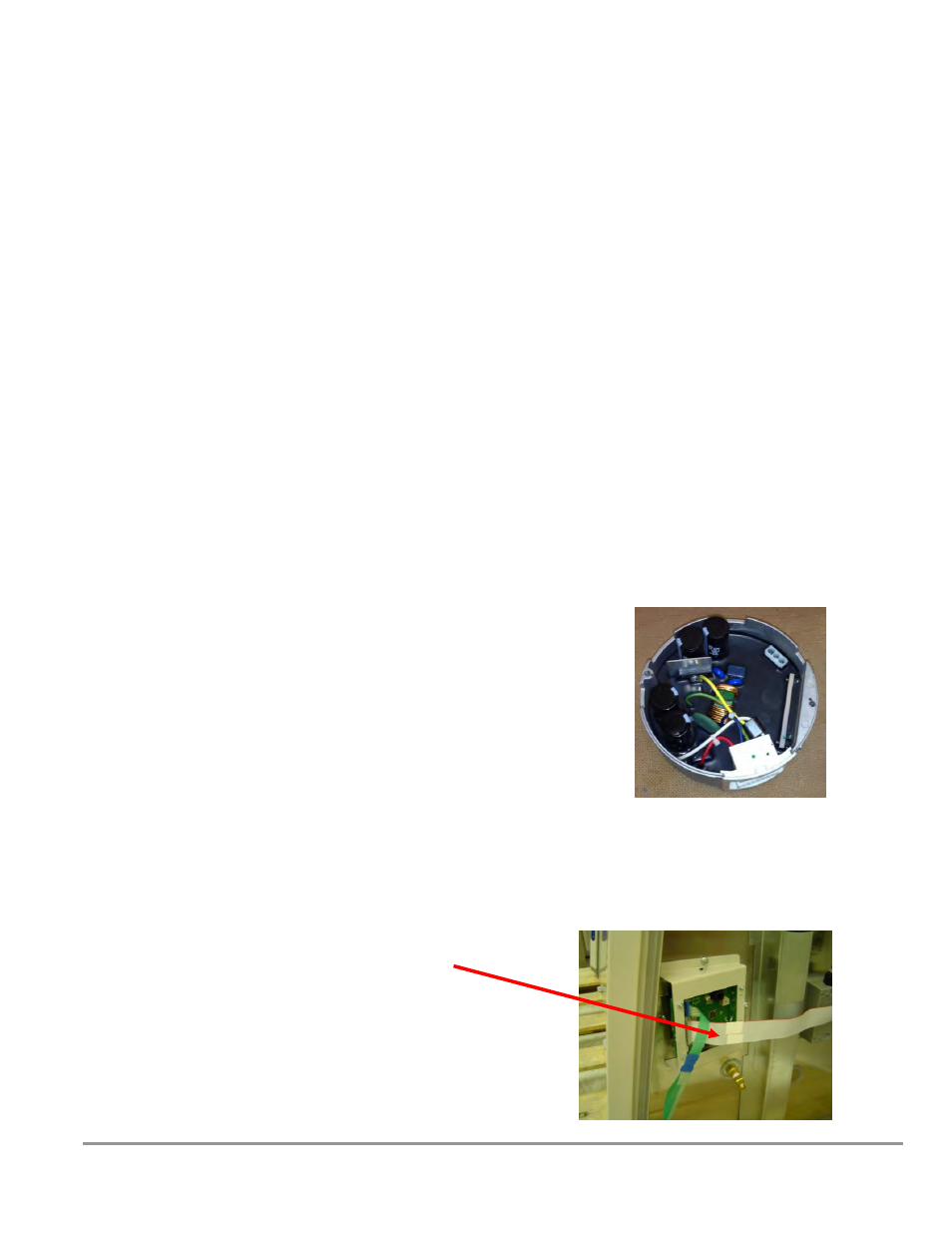

Electronics

The Axiom utilizes two microprocessors. The first is part of the ECM motor,

attached to end of the motor housing, as shown in Figure 1-10. This

processor controls motor operation, and communication with the display

board. The second is located on the control board, located on the right side

wall, as shown in Figure 1-11. It controls the display and its interface to the

touchpad.

Figure 1-10

The ECM Microprocessor board is encapsulated in

epoxy to prevent moisture and dirt contamination of

the microelectronics.

Figure 1-11

The control board assembly

(located on the right side wall)