Labconco Type C1 Biosafety Cabinet Models 30468 User Manual

Page 123

Product Service 1-800-522-7658

123

6.

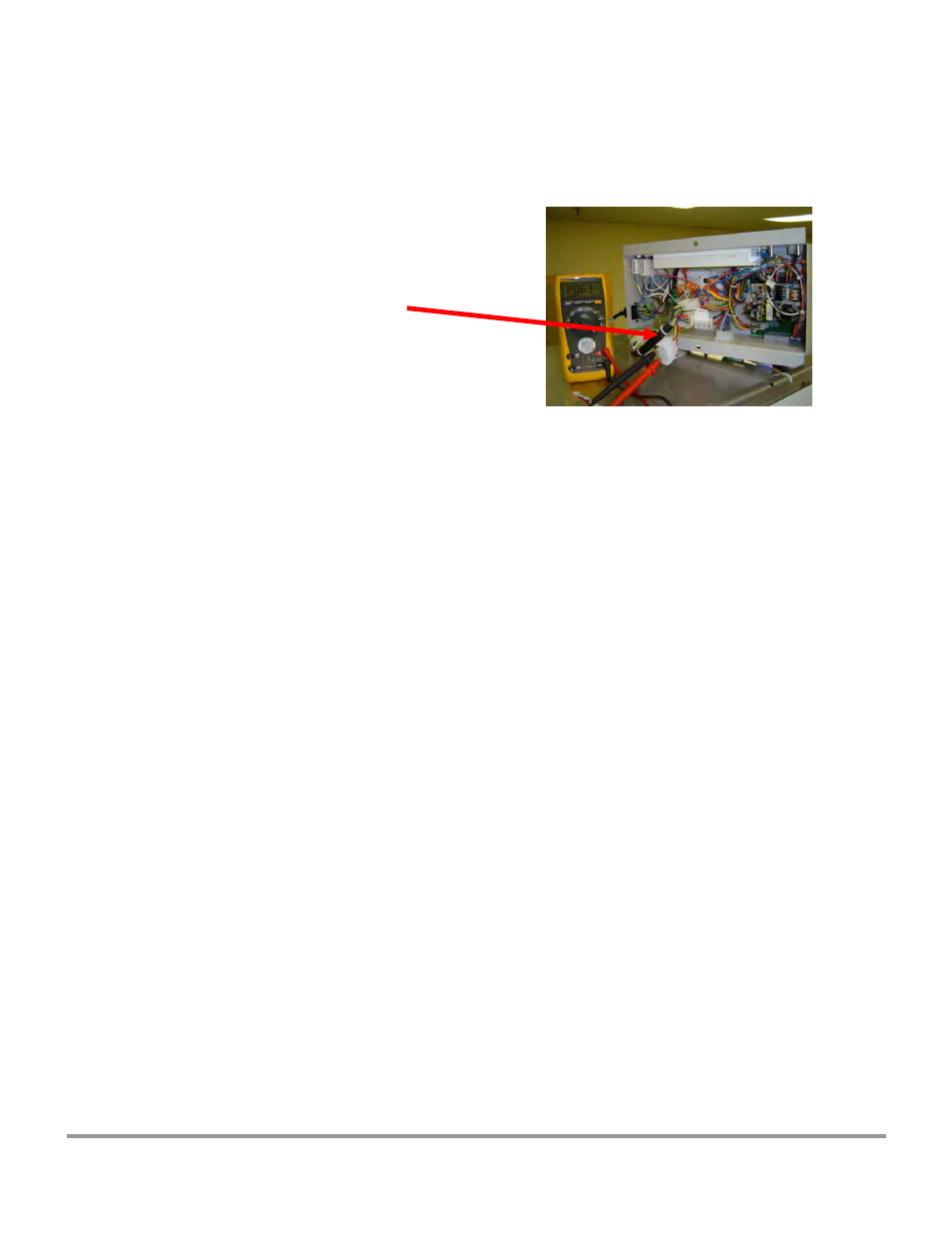

Next, connect the meters + DC voltage lead to pin 6 (yellow wire) and verify

there is 12 Volt DC, as shown in Figure 7-10. The presence of 12 Volt DC on

this yellow wire tells the motor to start.

Figure 7-10

Measuring 24 VDC voltage

7.

Next, move the meter’s + DC voltage lead to pin 5 (purple wire) [the meter’s lead

is still connected to pin 8 (brown wire)]. Note the DC voltage, since the motor’s

speed is determined by the pulse width modulated signal on this contact. A

voltage noted in step 6 signifies 100% pulse width duty cycle, while a DC voltage

of 0 volts would indicate a 0% PWM level. Depending on the particular ECM

motor, the motor speeds for the 0% PWM levels and 100% PWM levels will differ

but the 0% level represents the “night setback” blower speed and the 100% level

indicates the max speed ever required by the motor under total filter loading. The

actual DC voltage measured will be between 0 V and 24 Volts DC, and that voltage

indicates roughly the % duty cycle being sent to the motor at this time. For

example:

A total voltage of 12 VDC, and a signal voltage of 8.15 VDC would be:

8.15 VDC measured/12V DC @ 100% = 68% duty cycle.