Troubleshooting – Sears 385.12912 User Manual

Page 76

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

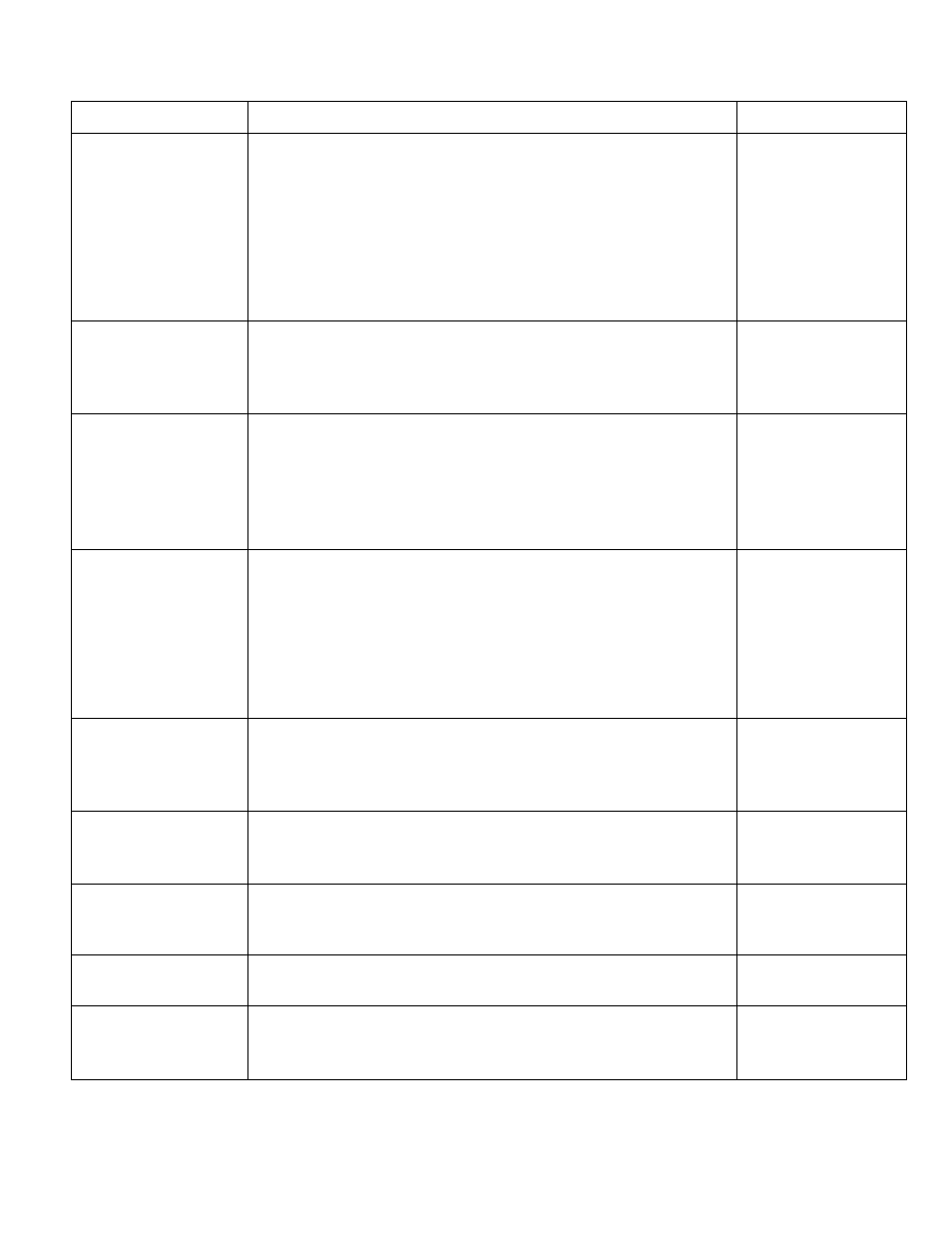

Troubleshooting

Condition

C^uso

Reference

^

The needle thread

breaks.

1 The needle thread is not threaded properly

2 The needle thread tension is too tight

3, The needle is bent or blunt

4, The needle is incorrectly inserted.

5 The needle thread and the bobbin thread are not set properly

under the presser fool when sewing is starting.

6 The fabric is not drawn to the rear when sewing is finished

7 The thread is too heavy or too fine for the needle

Page 24

Pages 26,28

Page 10

Page 10

Page 24

P

atia

Page 14

The bobbin thread

breaks.

1 The bobbin thread is not threaded properly in the bobbin

case and shuttie,

2, Lint has collected in the shuttle area.

3 The bobbin is damaged and doesn't turn smoothly.

Page 22

Page 64

Change the bobbin

The needle breaks.

1

The needle is incorrectly inserted

2 The needle is bent or blunt

3 The needle clamp screw is loose

4 The needle thread tension is too tight,

5, The fabric is not drawn to the rear when sewing is finished.

6 The needle is loo fine for the fabric being sewn

Page 10

Page 10

Page 10

Pages 26, 28

Page 32

Page 14

Skipped stitches

1 The needle is incorrectly inserted,

2 The needle is bent or blunt

3 The needle and/or threads are not suitable for the work being

sewn.

4 A blue needle is not being used for sewing stretch, very fine

fabrics and synthetics.

5 The needle thread is not threaded properly

6- The wrong needle is used.

Page 10

Page 10

Page 14

Page 14

Page 24

Change the needle

Seam puckering

1. The needie thread tension is too tight

2 The needle thread is not threaded properly,

3. The needle is too heavy for the fabric being sewn.

4 The stitch length is too bng for the fabric

Pages 26. 28

Page 24

Page 14

Make stitch denser

The cloth is not

feeding smoothly.

1 The machine is not plugged in

2, The stitches are too fine,

3 The feed dog is not raised after “drop feed" sewing.

Page 6

Make stitch coarser

Page 38

The machine

doesn't work.

1, The feed dog is packed with lint.

2 A thread is caught in the shuttle race

3. Push-clutch is disengaged

Page 62

Page 64

Pages 18, 20

Patterns are

distorted.

1 The stitch is not balanced

Page 30

Noisy operation

1

1, There is thread caught in the hook race.

2,, Lint has built up in the shuttie or the shuttie race.

Page 64

Page 64

.J

68