Top Flite TOPA0110 User Manual

Page 31

1/8" plywood former F-11, making it a notch. Test

fit F-11 into the fuselage. Make adjustments to

the notch if necessary. Glue in F-11.

45. Lightly sand a 22" length of outer pushrod

tube and feed it through the elevator pushrod

holes in the formers. Glue it to formers F-7

through F-10. NOTE: Refer to the plans for the

location of the aft end of the tube. It protrudes

past F-11 about 1/4".

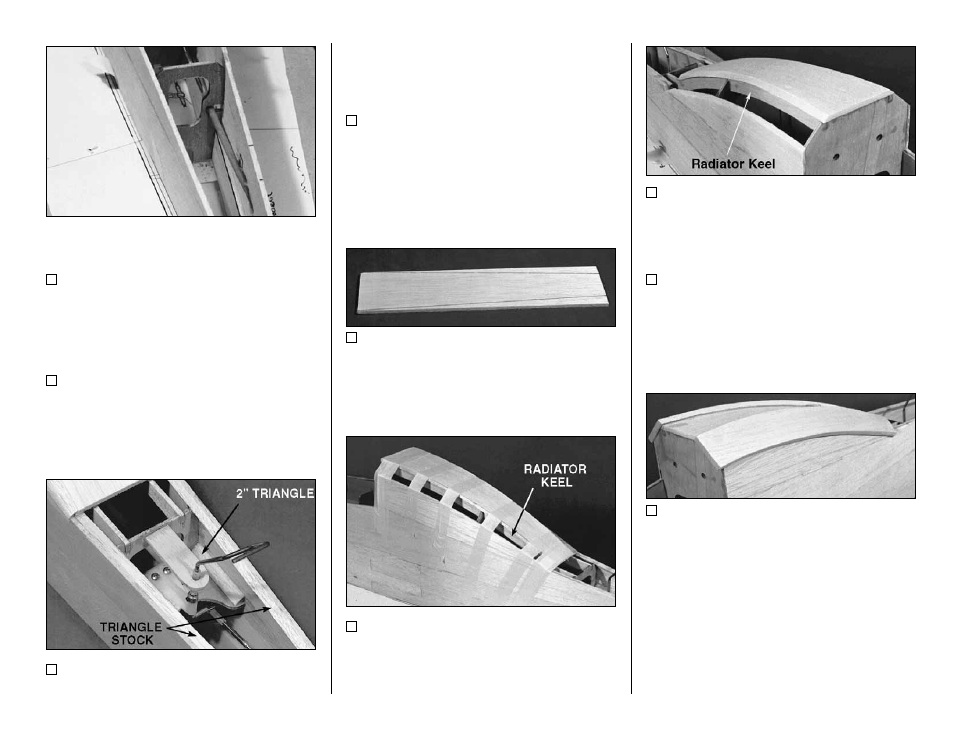

46. Cut two 2" lengths of 1/4" balsa triangle

stock and use them to reinforce the joints of TW

and the fuselage sides (see photo below).

47. Cut two 11-1/4" lengths from the supplied

1/4" x 36" triangle stock. Test fit these in the aft

f u s e l a g e a s s h o w n . N o t i c e o n t h e p l a n s

(sideview) that they stop 1/2" short of the aft end

of the fuselage sides. Glue them in place.

48. Test fit the die-cut 1/8" balsa Radiator

Keels into the slots in F-8, F-9, and F-10. You

may be required to shorten them slightly. Glue

them in place (see the photos at steps 50 and

51).

49. Cut an 11-3/4" length from the 3/16" x 3"

x 24" soft balsa Aft Fuse Bottom Sheet. Cut it

down until it is just wider than the two Keels.

50. Wet the sheet with water. Apply medium

CA glue to the keels, F-8, and F-9. Pull the sheet

into place with multiple pieces of masking tape.

Allow the wet wood to dry thoroughly.

51. Use a knife, a razor plane, and a coarse

sanding block to bevel the radiator sides and

bottom as shown. Look at the cross-sections on

the fuselage plans for reference.

52. Use the pattern provided on the plan to

cut two Radiator Corners from the 1/4" x 2" x 24"

soft balsa sheet.

5 3 . G l u e t h e R a d i a t o r C o r n e r s t o t h e

fuselage. Wetting these parts may be required,

depending on the wood. You may wish to use

tape to hold these parts down while the glue sets.

NOTE: At this point, you should

remove the fuselage from the building

board and reinforce difficult to reach

glue joints from the inside.

- 31 -