2 troubleshooting, Service (cont’d), Check the light on the dsi control board – Reznor VR Unit Installation Manual User Manual

Page 43

Form I-VR, P/N 205202 R13, Page 42

10.2 Troubleshooting

WARNING: Service work on this heater should only be done by a qualified gas service

person. All service information including the Troubleshooting Guides is intended as

an aid to a qualified service person.

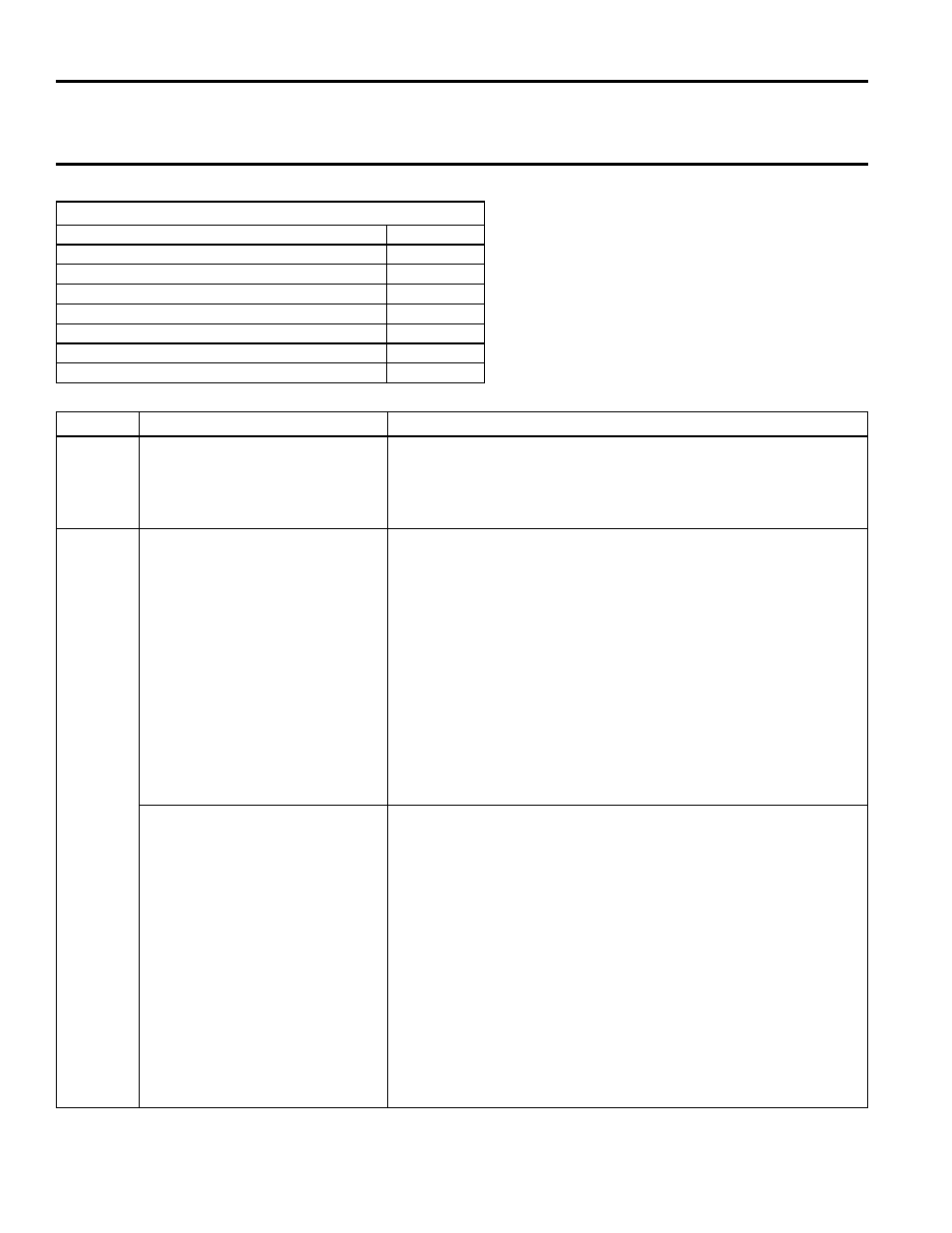

Check the Light on the DSI Control Board

The DSI control board monitors the operation

of the heater and includes a LED signal light

that indicates normal operation and various

abnormal conditions. If the heater fails to oper-

ate properly, check this signal to determine the

cause and/or to eliminate certain causes. See

operation sequence on the Wiring Diagram in

FIGURE 31 or on the heater.

Do not attempt to repair the DSI control board.

10. Service (cont’d)

LED Codes

No power

Steady OFF

Power applied, control OK

Steady ON

Pressure switch open with blower motor ON

1 FLASH

Pressure switch closed with blower motor OFF 2 FLASHES

Lockout from too many ignition trials

3 FLASHES

Lockout from too many flame losses

4 FLASHES

Control hardware fault detected

5 FLASHES

Lockout from too many pressure switch losses 6 FLASHES

PROBLEM PROBABLE CAUSE

REMEDY

Blower

motor will

not start

1. No power to unit.

1. Turn on power; check supply fuses or main circuit breaker.

2. No 24 volt power to DSI control board. 2. Turn up thermostat; check control transformer output.

3. No power to blower motor.

3. Tighten connections at DSI board and/or motor terminals.

4. DSI control board defective.

4. Replace DSI control board.

5. Defective blower motor.

5. Replace blower motor. See Paragraphs 9.2.7 and 10.1.

Burner will

not light

1. Manual valve not open.

1. Open manual valve.

2. Air in the gas line.

2. Bleed gas line (initial startup only).

3. Gas pressure too high or too low.

3. See Gas Supply Pressure Table, Paragraph 6.3.

4. No Spark:

4.

a) Loose wire connections.

a) Be certain all wire connections are solid.

b) Transformer failure.

b) Be sure 24 volts is available.

c) Incorrect spark gap.

c) Maintain spark gap at 1/8”.

d) Spark wire shorted to ground.

d) Replace DSI electrode assembly.

e) Spark electrode shorted to ground.

e) Replace if ceramic spark electrode is cracked or grounded.

f) DSI board not grounded.

f) Make certain DSI control board is grounded to furnace chassis.

g) Unit not properly grounded.

g) Make certain unit is properly field grounded to earth ground.

j) Faulty DSI control board.

j) If 24 volt is available to the DSI control board and all other causes have been

eliminated, replace board.

5. Lockout device interrupting control

circuit by above causes.

5. Reset lockout by interrupting control at the thermostat for 5 seconds or main

power for 0.25 seconds.

6. Combustion air proving switch

not closing.

6.

a) Make sure unit is properly vented.

b) Remove obstructions from vent.

c) Replace faulty tubing to pressure switch.

7. Faulty combustion air proving switch. 7. Replace combustion air proving switch.

8. Main valve not operating.

8.

a) Defective valve.

a) If 24 volt is measured at the valve connections and valve remains closed,

replace valve.

b) Loose wire connections

b) Check and tighten all wiring connections.

9. DSI control board does not power

main valve.

9.

a) Loose wire connections.

a) Check and tighten all wiring connections.

b) Spark electrode assembly grounded. b) Be certain spark electrode assembly lead is not grounded or insulation or

ceramic is not cracked. Replace as required.

c) Incorrect gas pressure.

c) See Gas Supply Pressure Table, Paragraph 6.3.

d) Cracked ceramic at spark electrode

assembly.

d) Replace spark electrode assembly.