Mechanical -31, 1 prepare the burner/control box, Mechanical – Reznor VR Unit Installation Manual User Manual

Page 10

Form I-VR, P/N 205202 R13, Page 9

6. Mechanical

Each straight tube section must have a suspension point. Straight sections

adjacent downstream to a “U” or “L” tube require two suspension points.

There must be a suspension point within 12 inches (305mm) of every

coupler.

Since the heater must be level, a turnbuckle is recommended at each

suspension point. Turnbuckles must be of steel or malleable iron. Use

either an optional turnbuckle kit or field-supplied equivalent. Turnbuckle

Option 15-22 Kits include the quantity of turnbuckles required by length of

heater.

Refer to Paragraph 2 for recommended minimum mounting heights. The

installer is responsible for properly and adequately fastening the chains

to the building and supporting the weight of the heater. Depending on

the type of building construction, either attach the chain support directly

to the building or attach and extend a support to the location needed.

SUPERSTRUT

®

brackets or a comparable metal strut material is well

suited as a support structure that requires numerous suspension points.

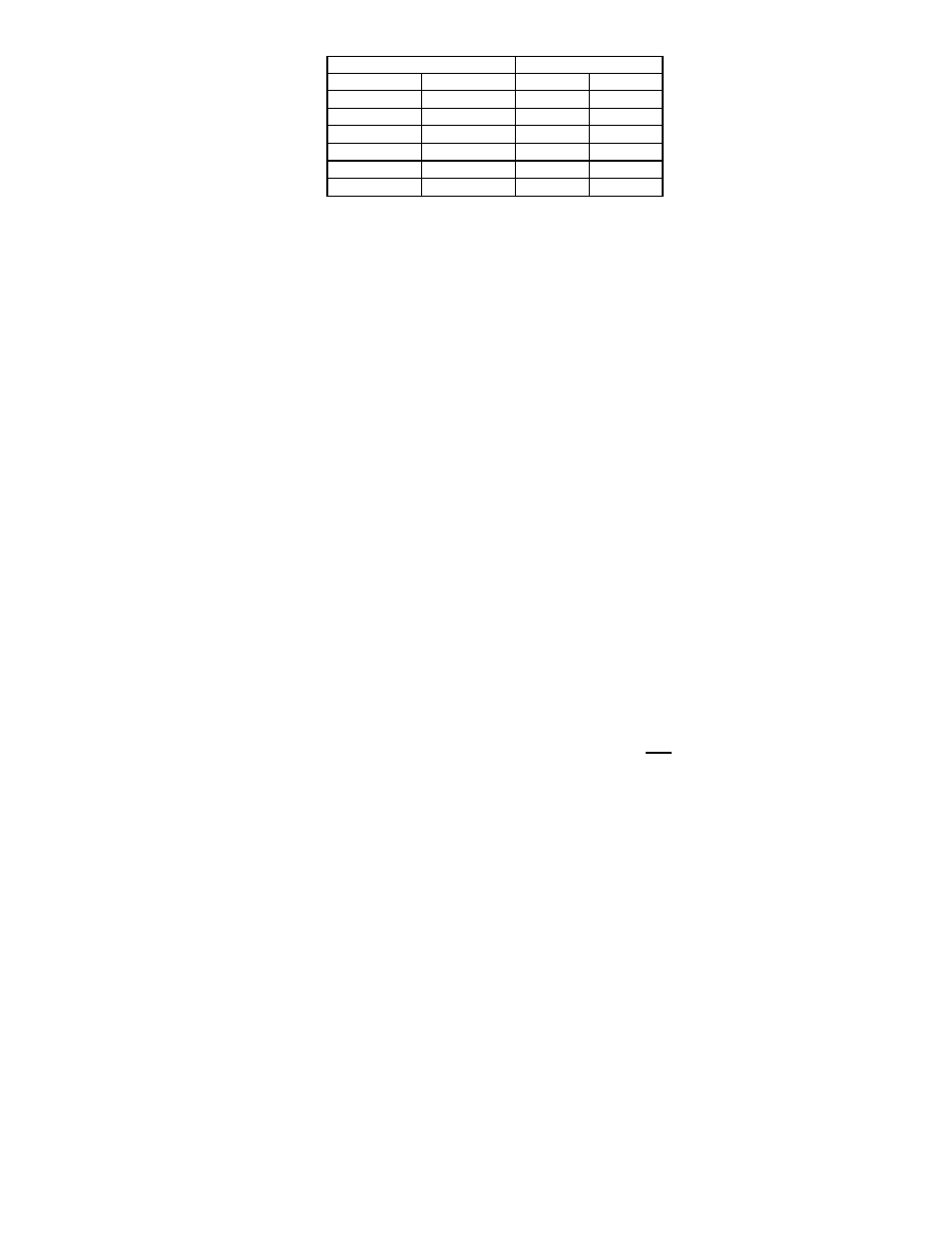

Straight System Length

Expansion

ft

M

inches

mm

70 ft

21.3

2-3/4

70

60 ft

18.3

2-3/8

60

50 ft

15.2

2-1/8

54

40 ft

12.2

1-7/8

48

30 ft

9.1

1-1/2

38

20 ft

6.1

1-1/8

29

6.1 Prepare the Burner/Control Box

There are very important steps that must be followed to prepare, assemble,

and suspend these tubular radiant heaters. Preparing the heater, suspension,

and field assembly are the responsibility of the installer. Follow all instructions

carefully.

All burner/control boxes require some field preparation. The type of preparation

depends on how the unit was ordered and where it will be installed. Determine

which of these two situations match your application and follow the appropriate

instructions. (Refer to Paragraph 3 for explanation on packaging.)

•

The unit was ordered as a specific size OR as a VR 75/100, VR

125/150, or VR 175/200 and is being installed as a Size 75, 125, or 175.

Proceed to

STEP 2) of the Preparation Instructions. (Skip STEP 1.)

•

The unit was ordered as a VR 75/100, VR 125/150, or VR 175/200 and

is being installed as a Size 100, 150, or 200.

Proceed to

STEP 1) of the Preparation Instructions. Complete both STEP 1

and 2.

Preparation

INSTRUCTIONS:

STEP 1) Change Components to Field Convert the Model VR

Burner/Control Box Size 75,000 to 100,000; Size 125,000 to

150,000; or Size 175,000 to 200,000.

Parts Required: Conversion kit shipped with the burner/control box. All kits

include a burner orifice, a combustion air restrictor plate, and conversion label.

A Size 200 kit also includes a pressure switch.

1. Conversion Size Label - Fill-in the label stating that the burner/control box

has been converted to either a Size 100,000, 150,000 or 200,000.

2. Change Air Restrictor Plate - Refer to FIGURE 4 and identify the com-

bustion air restrictor plate on the side of the burner box. Remove the three

or four nuts holding the factory-installed restrictor plate; save the nuts and

discard the restrictor plate. Using the same nuts, attach the combustion air

restrictor plate shipped in the parts bag.