Service (cont’d), Pressure switch, Figure 39 - pressure switch – Reznor VR Unit Installation Manual User Manual

Page 41

Form I-VR, P/N 205202 R13, Page 40

Pressure Switch

Function - The pressure switch is a safety control to ensure that adequate air

is being provided for proper combustion. The device “senses” a small differen-

tial pressure created by the flow of the combustion air.

Sensing Pressure Check (requires a Phillips screwdriver, a sensitive slope

gauge, several feet of 3/16” O.D. rubber tubing, and two 1/4” O.D. barbed

tees)

1) Disconnect the electrical supply and open the control compartment door.

2) Using one of the tees, attach tubing to one side of the pressure switch so

that the switch will continue to sense pressure. Repeat on the other side of

the pressure switch.

3) Connect the tubing to the slope gauge being careful not to “mix” the tubes.

4) Turn on the electrical power, and set the room thermostat above room

temperature.

5) On the slope gauge, take the “cold” readings. If the “cold” sensing pressure

is sufficient to cause the pressure switch to close, observe at what sensing

pressure the switch opens (“hot”).

FIGURE 39 -

Pressure Switch

Service - The pressure switch is a very reliable device which has no field-

repairable parts and seldom needs to be replaced. Usually a pressure sens-

ing problem is an indication that there is a problem with the vent pipe and/or

combustion air inlet. The most likely causes of low sensing pressure are listed

below.

On new installations, the cause is usually due to either too much vent pipe,

too much combustion air inlet pipe, and/or the use of non-specified termi-

nals. (See Paragraphs 6.2 and 6.4.)

On units that are not equipped with an outside combustion air inlet, low

sensing pressure may be caused by negative building pressure. When

negative building pressure exists, install an outside combustion air inlet.

An obstruction in the vent pipe or combustion air inlet. Remove obstruction.

A dirty combustion air blower wheel. See Maintenance Section, Paragraph

9.2.7, for cleaning instructions.

Check the installation, make necessary changes, and re-check the sens-

ing pressure. If it should be determined that the pressure switch needs to be

replaced, replace with an identical switch only. Do not substitute.

WARNING: If

replacement of the

pressure switch is

necessary, replace

with the identical

model pressure

switch only.

Do not substitute.

NOTE: A Model VR/GVR

50-175 operating above

6000 ft (1830M) elevation

requires a high altitude

pressure switch. See

Paragraph 6.1.

10. Service (cont’d)

10.1 Control

Location,

Operation,

and Service

(cont’d)

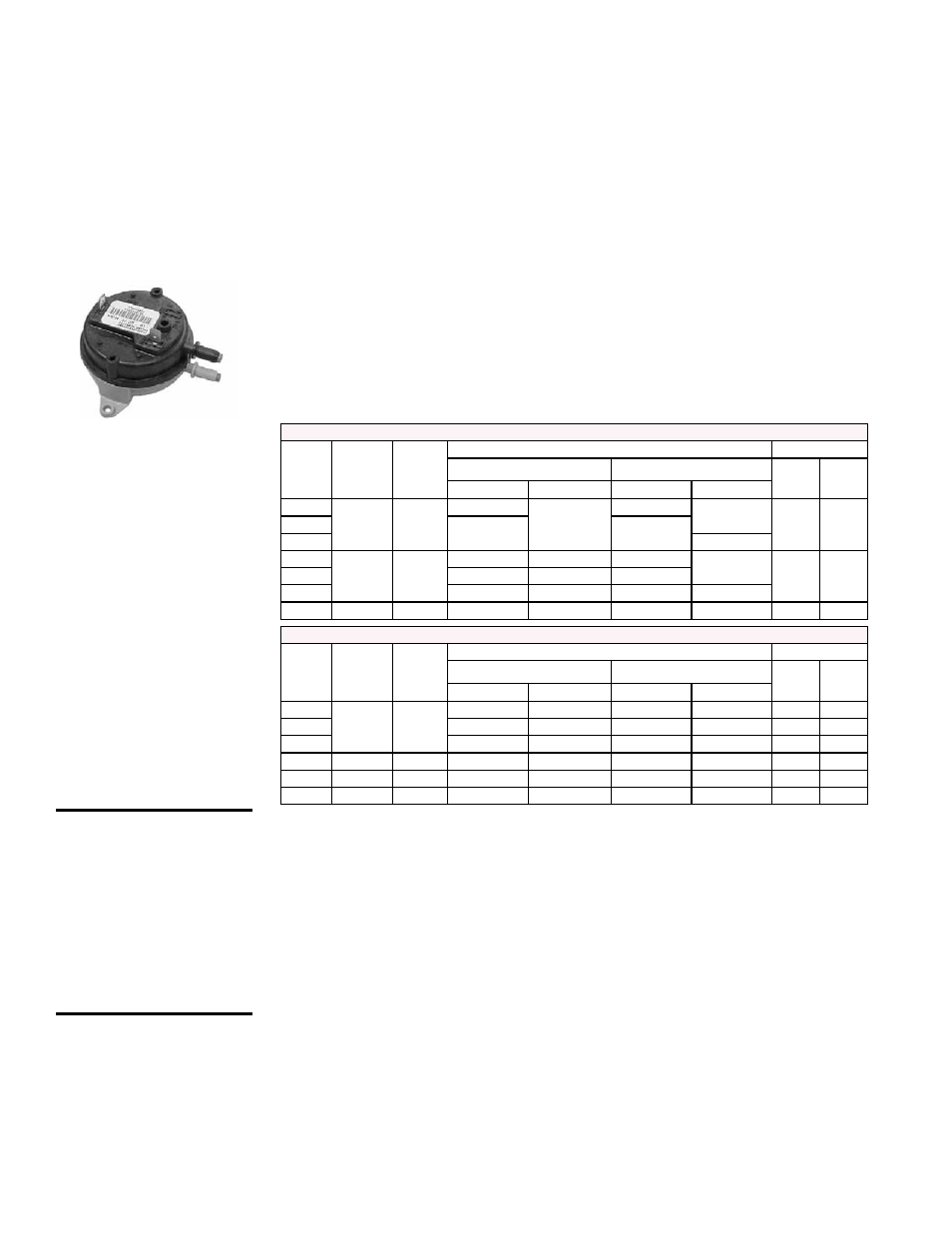

Model VR (60 Hz) Combustion Air Pressure Switch Settings

Size

Pressure

Switch

P/N

Label

Color

Normal Sensing Pressure Range (“w.c.)

Setpoint

Indoor Combustion Air

Outdoor Combustion Air

“OFF”

“ON”

Cold

Hot

Cold

Hot

50

205442

White

0.75 - 0.65

0.65 - 0.55

0.72 - 0.62

0.60 - 0.50

0.20

0.25

75

0.85 - 0.75

0.75 - 0.65

100

0.55 - 0.45

125

205443

Yellow

1.70 - 1.40

1.35 - 1.15

1.65 - 1.35

1.20 - 1.00

0.75

0.80

150

1.80 - 1.50

1.30 - 1.10

1.60 - 1.30

175

2.50 - 2.20

1.80 - 1.55

2.30 - 2.00

1.60 - 1.35

200

205444

Green

2.00 - 1.70

1.10 - 0.85

1.70 - 1.40

0.80 - 0.55

0.30

0.35

Model VR or Model GVR (50 Hz) Combustion Air Pressure Switch Settings

Size

Pressure

Switch

P/N

Label

Color

Normal Sensing Pressure Range (“w.c.)

Setpoint

Indoor Combustion Air

Outdoor Combustion Air

“OFF”

“ON”

Cold

Hot

Cold

Hot

50

205442

White

0.65

0.50

0.60

0.50

0.20

0.25

75

0.75

0.50

0.65

0.40

0.20

0.25

100

0.70

0.45

0.60

0.40

0.20

0.25

125

197032

Pink

1.10

0.80

1.00

0.65

0.45

0.50

150

205444

Green

1.10

0.60

1.00

0.50

0.30

0.35

175

197031

Purple

1.10

0.50

0.80

0.50

0.35

0.40