Maintenance (cont’d) – Reznor VR Unit Installation Manual User Manual

Page 37

Form I-VR, P/N 205202 R13, Page 36

9.2.5 Connection

Couplings

S

Check the bolts and screws on the tube couplings for tightness. Loose

couplings will allow flue products and/or flame to escape into the heated space.

Tighten all bolts and screws. Replace if damaged.

CAUTION: Use of

eye protection is

recommended.

1) Turn off the electrical supply to the heater, open the control access panel,

and rotate the knob on the gas valve to the “OFF” position.

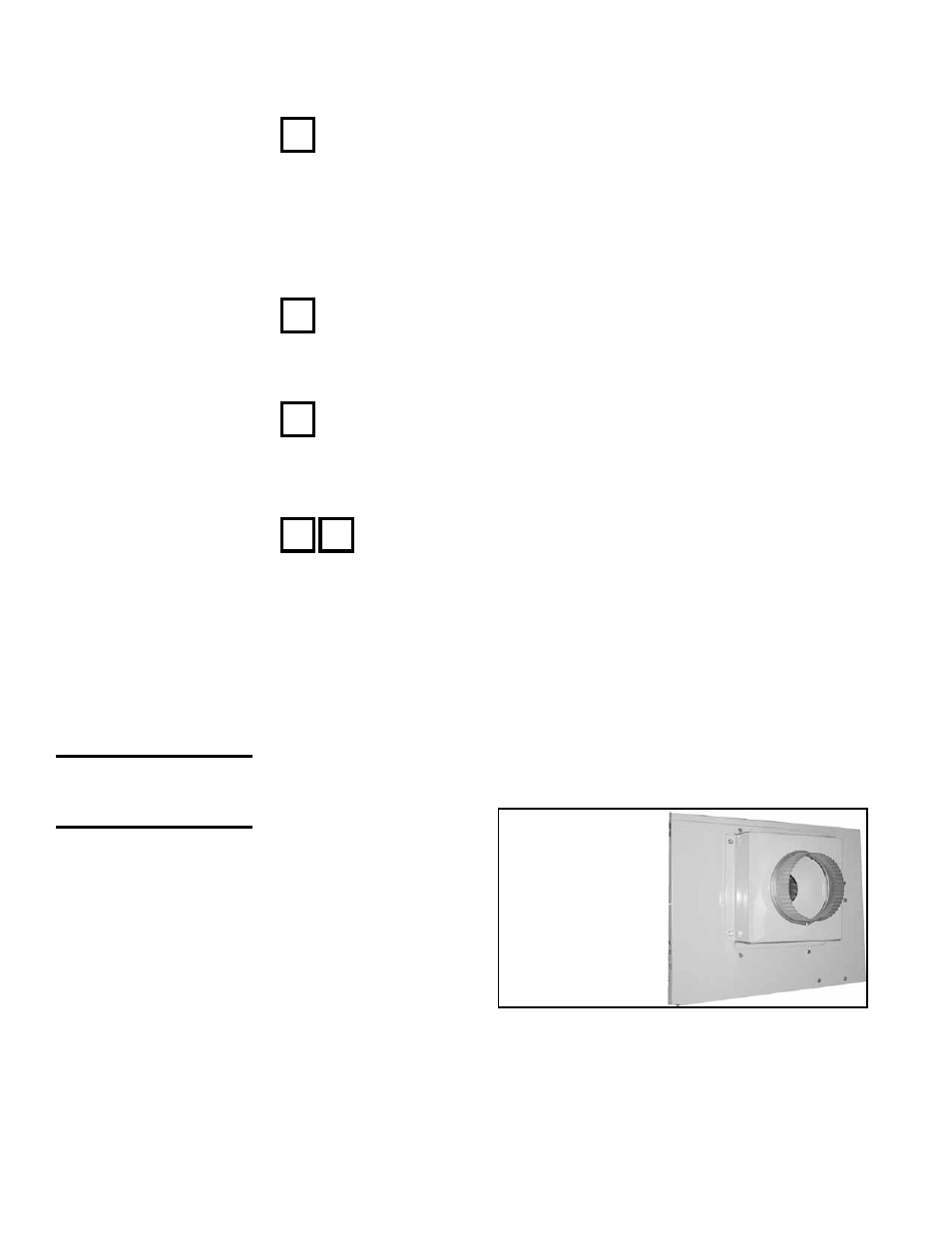

FIGURE 33 -

Combustion Air

Inlet Cover used

with Optional

Outside

Combustion Air

9. Maintenance (cont’d)

9.2 Maintenance Procedures (cont’d)

9.2.6 Vent and/or

Combustion Air

Terminal

R

To prevent the pressure switch from cycling, check the vent terminal

and the combustion air inlet terminal (if equipped with the combustion air inlet

option) for any restrictions and/or damage.

Clean if restricted, and replace if damaged.

9.2.7 Combustion Air

System

R

S

During an average heating season, approximately 65 tons of air pass

through a Size 100 burner. That air is always carrying some dirt. Obviously, the

amount of dirt varies with the environment. As the air passes through, some of

that dirt is deposited on the combustion air intake, on the combustion air blower

wheel, and inside the main burner. This buildup of dirt will eventually affect

the operation of the heater. To maintain safe and reliable heater operation, an

annual cleaning (more frequently in dirty environments) is recommended.

Instructions for Cleaning the Combustion Air Blower (requires a wire

brush, cleaning cloth, and an automotive-type aerosol degreaser or

refrigerant coil cleaner):

3) Open the burner access panel on the bottom of the burner/control box.

Either (1) cover the air inlet to the main burner to prevent foreign debris

from entering the burner tube or (2) remove the burner for cleaning (Refer

to Paragraph 34 on Cleaning the Main Burner).

4) Remove the combustion air restrictor plate (

FIGURE 34) and screen. The

combustion air blower wheel is now visible (

FIGURE 35).

2) If using outside air for

combustion, remove

the combustion air

inlet cover (Refer to

FIGURE 33). It is not

necessary to discon-

nect the pipe. Remove

the inlet cover with the

pipe attached.

S

During a “cold” startup, transient condensation is formed. Over a period

of time, condensation will cause metal pipe to develop holes and eventually fail

completely. Replace any vent pipe that has condensation damage. The vent

pipe system should be maintained at a quality where all flue products will be

conveyed through the vent pipe to the outdoors.

If equipped with an optional dual vent kit, remove the cover from the dual vent

adapter box to check the inner pipe.

9.2.4 Vent Pipe