Mechanical (cont’d) – Reznor VR Unit Installation Manual User Manual

Page 31

Form I-VR, P/N 205202 R13, Page 30

DANGER: The fresh air requirement of 4 CFM per 1000 BTUH

for natural gas and 5 CFM per 1000 BTUH for propane gas is

mandatory when operating a heater in the unvented mode. See

Hazard Levels, page 2.

•

Do not operate in the unvented mode if there is any doubt about the qual-

ity of the insulation in the building. Unvented operation in a building that

has an uninsulated roof or that may have uninsulated structural members

partially exposed to the outdoors may result in condensation. The conden-

sation may be severe enough to drip and/or cause corrosion.

•

Do not install in the unvented mode with outside combustion air unless the

inlet air cap is at or below the plane of the heater.

When installing a heater in the unvented mode, a vent cap must be used and

must be inverted as illustrated in

FIGURE 29. Install the elbow as shown in FIG-

URE 25 but in addition to securing the elbow with one screw on the top, secure

it to the compression coupling using two additional non-corrosive sheetmetal

screws with all three screws spaced approximately 120° apart. Attach the vent

cap to the 90° elbow in the same manner with three sheetmetal screws.

When a heater is operated without being vented to the outdoors,

the TOP

clearance to combustibles is 18” (457mm); see Paragraph 4.3.

The burner is equipped with a centrifugal blower to provide combustion air. The

air for combustion can come either from the heated space or be piped directly

from the outside. Combustion air should be piped from the outside if (1) the

pressure in the building is negative, (2) the atmosphere is dirt laden, (3) the

atmosphere contains any substance that will cause toxic gas when passed

through a flame, or (4) the heater is installed in a tightly closed room that does

not provide required air for combustion.

If drawing combustion air from the heated space, the screened combus-

tion air opening on the burner box must be kept clean. Maintain a minimum 12”

clearance from the combustion air inlet opening. If the heater is located in a

tightly closed room and is not equipped with a combustion air inlet pipe, provi-

sion must be made to supply air for combustion to the room.

The requirements for combustion and ventilation air depend upon whether the

unit is located in a confined or unconfined space. An “unconfined” space is

defined as a space whose volume is not less than 50 cubic feet per 1000 BTUH

of the aggregate input rating of all appliances installed in that space. Under all

conditions, enough air must be provided to ensure there will not be a negative

pressure condition within the equipment room or space.

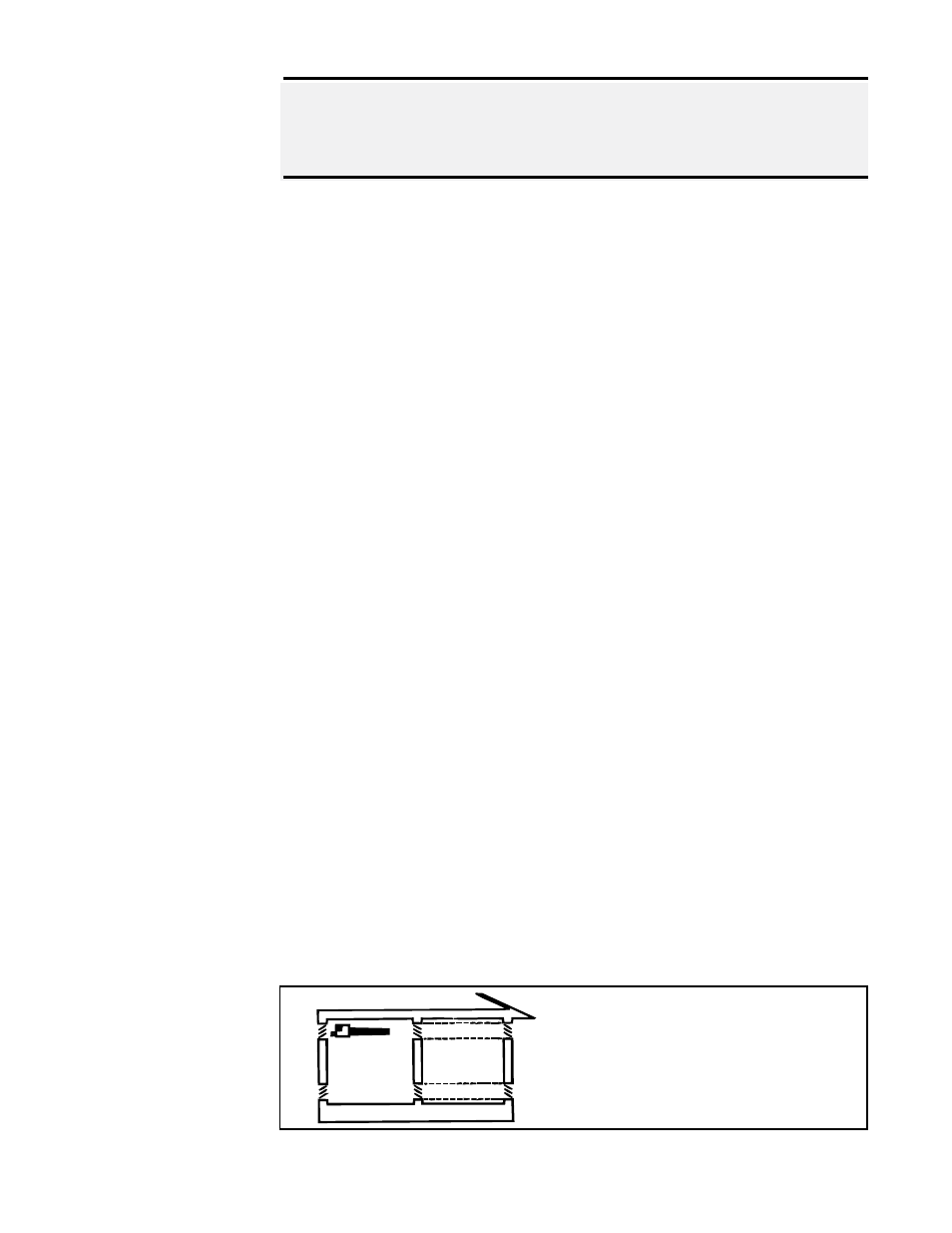

Do not install a unit in a confined space without providing wall openings lead-

ing to and from this space. Provide adequate openings near floor and ceiling

for ventilation and air for combustion, as shown in

FIGURE 30, depending on

combustion air source as noted below.

6.4.4 Combustion Air

Confined

Space

(3)

(3)

(1)

(1)

(2)

(2)

FIGURE 30 -

Combustion Air

and Ventilation

Requirements for a

Confined Space

Confined Space: A space whose

volume is less than 50 cubic feet

per 1000 BTUH of the aggregate

input rating of all appliances

installed in that space.

6.4 Venting and

Combustion Air

(cont’d)

6. Mechanical

(cont’d)

Add total BTUH of all appliances in the confined space and divide by figures

below for square inch free area size of each (top and bottom) opening.

6.4.3 Unvented Installation (cont’d)