4 venting and combustion air, Mechanical (cont’d), 3 gas piping and pressures (cont’d) – Reznor VR Unit Installation Manual User Manual

Page 25

Form I-VR, P/N 205202 R13, Page 24

and 14” w.c. for Sizes 175-200. For propane gas, the inlet pressure must

be between 11” and 14” w.c. Take this reading as close as possible to the

heater (Heaters are equipped with gas valves that have an inlet pressure

tap.) If the inlet pressure is not within the specified range, the inlet pressure

must be corrected and Steps 3 and 4 repeated.

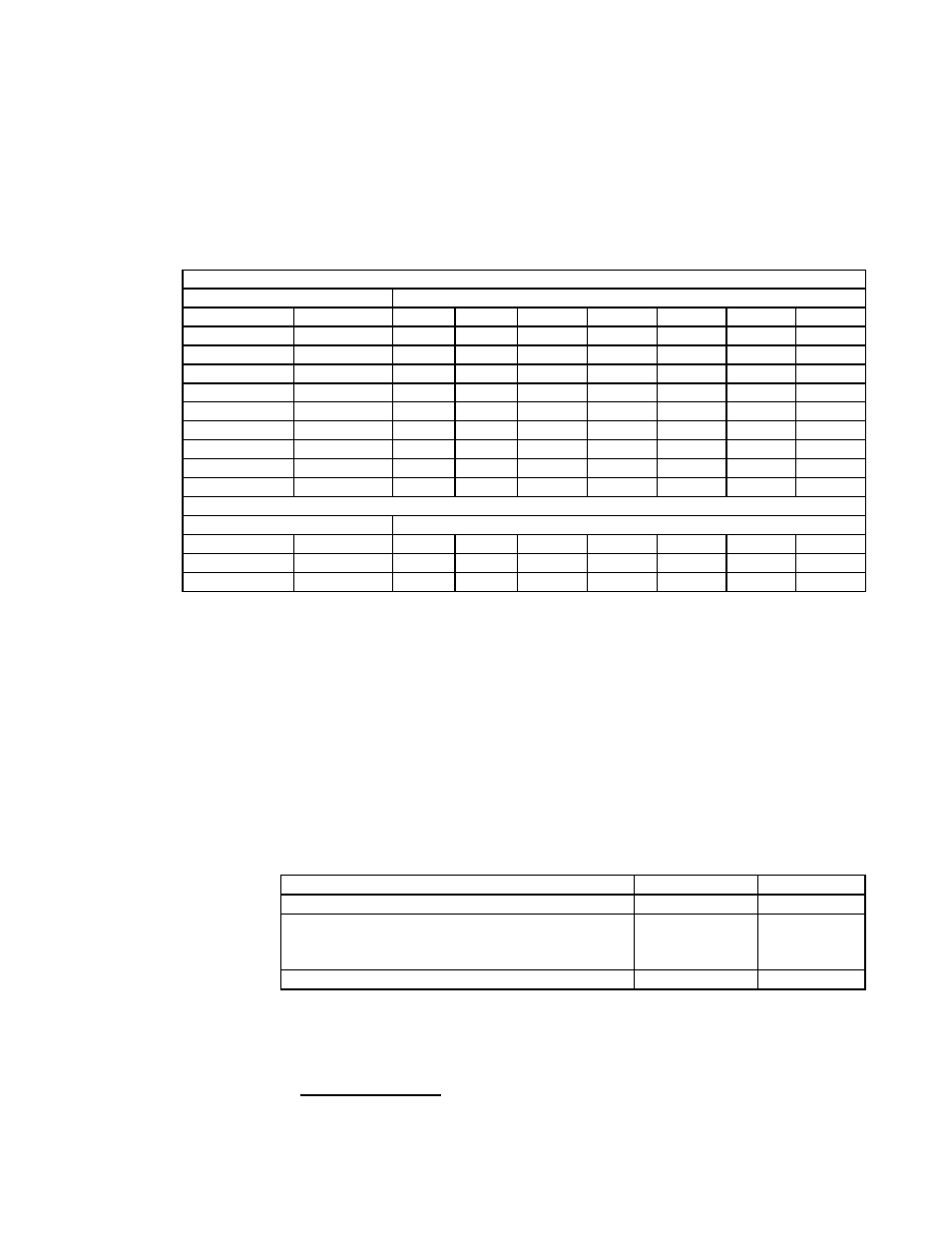

6. Find the High Altitude Adjustment label in the plastic bag that contained

these instructions. Using a permanent marker, fill-in the appropriate infor-

mation from the tables below. Select a position for the label on the rear of

the burner/control box adjacent to the rating plate. Be sure the surface is

clean and dry and adhere the label.

BTUH Inputs

by Altitude

BTUH Inputs by Altitude in the United States

ALTITUDE

NORMAL INPUT

Feet

Meters

Size 50 Size 75 Size 100 Size 125 Size 150 Size 175 Size 200

0 - 2000

0 - 610

50000

75000

100000

125000

150000

175000

200000

2001 - 3000

611 - 915

44000

66000

88000

110000

132000

154000

176000

3001 - 4000

916 - 1220

42000

63000

84000

105000

126000

147000

168000

4001 - 5000

1221 - 1525

40000

60000

80000

100000

120000

140000

160000

5001 - 6000

1526 - 1830

38000

57000

76000

95000

114000

133000

152000

6001 - 7000

1831 - 2135

36000

54000

72000

90000

108000

126000

144000

7001 - 8000

2136 - 2440

34000

51000

68000

85000

102000

119000

136000

8001 - 9000

2441 - 2745

32000

48000

64000

80000

96000

112000

128000

9001 - 10000

2746 - 3051

30000

45000

60000

75000

90000

105000

120000

BTUH Inputs by Altitude in Canada

ALTITUDE

NORMAL INPUT

Feet

Meters

Size 50 Size 75 Size 100 Size 125 Size 150 Size 175 Size 200

0 - 2000

0 - 610

50000

75000

100000

125000

150000

175000

200000

2001 - 4500

611 - 1373

45000

67500

90000

112500

135000

157500

180000

6.4 Venting and

Combustion Air

Venting must be in accordance with the National Fuel Gas Code NFPA 54/

ANSI Z223.1 (latest edition) or CAN/CSA B149.1 (latest edition), and all local

codes.

The ANSI standard applicable to this heater does not require venting catego-

rization. If such a requirement existed, this heater would be in Category III.

(Category III appliances have a positive-pressure vent requiring a gas tight

sealed vent system.) These tubular infrared heaters have been designed to

operate safely and efficiently with vent pipe lengths shown in the Vent Length

Table below. Vent systems may either be vertical or horizontal. The type of vent

required depends on the size of heater and the vent run configuration.

6. Mechanical

(cont’d)

Vent Category Table

Type of Vent Required by Vent Category

Model Sizes

50, 75, 100, 125 150, 175, 200

-- with a Horizontal Vent Run

Category III

Category III

-- with a Vent Run that is at least 1/2 vertical

(using equivalent lengths from the Vent Length

Table below)

Category I or

Category III

Category III

-- with a Dual Vent Adapter, Option CC5

Category III

Category III

Vent terminal end may be either single-wall pipe or double-wall pipe. A vent

terminal cap is required. Dual venting of two units is permissible when using

an Optional Dual Vent Kit (Option CC5). Comply with the specific requirements

and instructions in the following paragraphs.

1. Vent Pipe Length - The vent lengths shown in the Vent Length Table are

based on (1) the maximum permissible resistance to flow at which each model

size will operate and (2) the potential for continuous condensing. Condensing

in the vent pipe should not occur after equilibrium has been reached when the

6.4.1 Specific Venting

Requirements

6.3 Gas Piping

and Pressures

(cont’d)