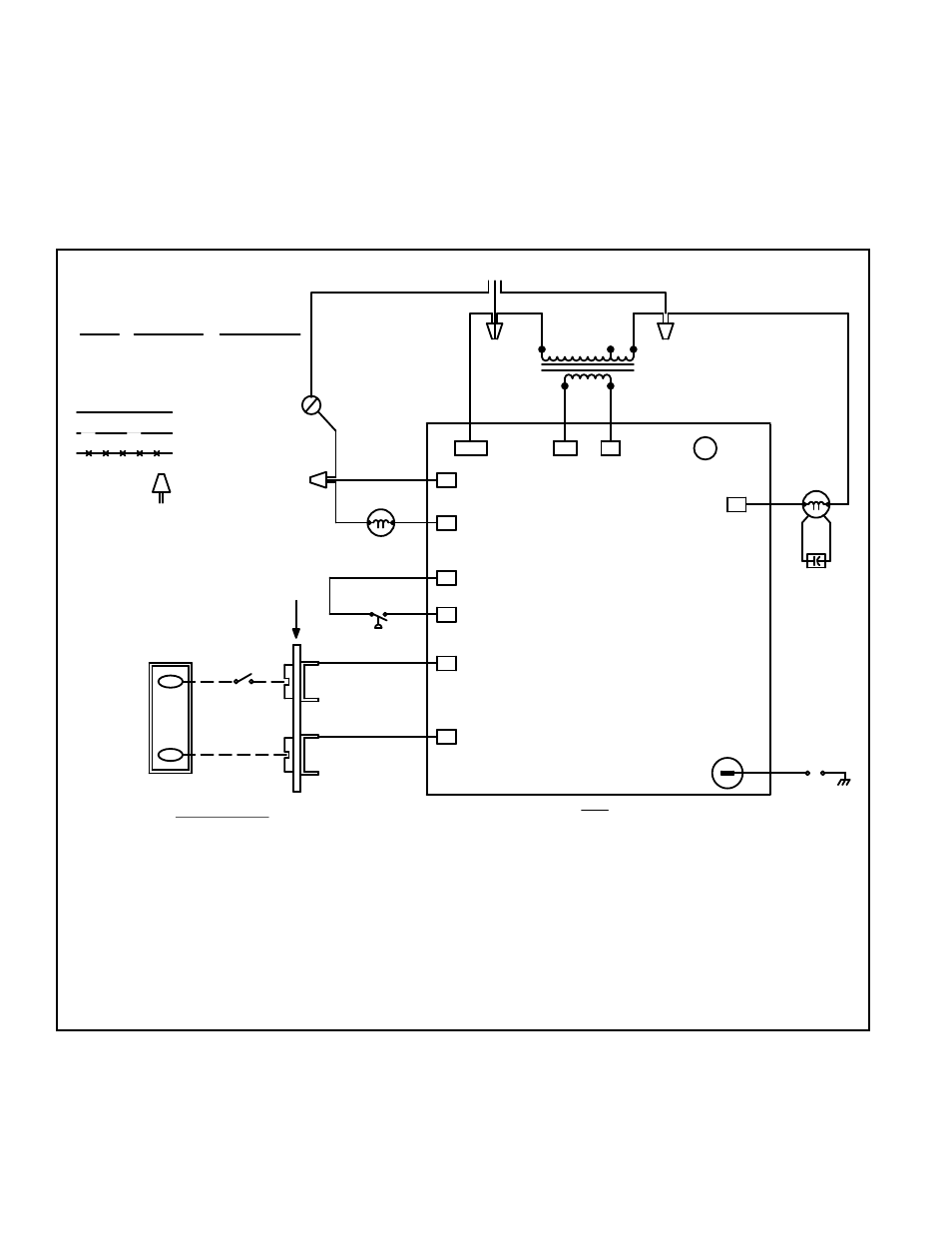

1 wiring diagram 7.2 control thermostat, Electrical and wiring (cont’d), 2 control thermostat – Reznor VR Unit Installation Manual User Manual

Page 33: 1 wiring diagram, Led flash codes, Figure 31 - wiring diagram, Dsi control

Form I-VR, P/N 205202 R13, Page 32

7.2 Control

Thermostat

FIGURE 31 - Wiring Diagram

7. Electrical and

Wiring (cont’d)

directly from the main electrical panel to the heater. All external wiring must be

within approved flexible conduit and have a minimum temperature rise rating

of 60°C. Conduit must not be run directly under the infrared tubes and should

not interfere with the heater access panel. Allow slack in the flexible conduit to

allow for heater expansion and contraction.

If the heater has field-installed options that require electrical connections, con-

sult the instruction sheet and wiring diagram supplied in the option package.

7.1 Wiring Diagram

The heater is designed for automatic control from a remotely positioned or

optional unit-mounted 24-volt thermostat and is equipped with a terminal strip

to facilitate thermostat connections. See

FIGURE 32.

Use either an optional thermostat (Option CL1) or a field-supplied 24-volt ther-

mostat. Do not attempt to operate with a line voltage thermostat. Locate a

remote thermostat on an inside wall in the heated area but not in the direct path

Refer to the wiring diagram in

FIGURE 31 or the diagram on the burner control

box door.

WD# 204374

VR SERIES

REV. #3

BLOWER MOTOR

PRESSURE SWITCH

SPARK GAP

FIELD CONTROL WIRING

150'

250'

350'

75'

125'

175'

#18 GA. WIRE

#16 GA. WIRE

#14 GA. WIRE

TOTAL WIRE

LENGTH

DISTANCE FROM

UNIT TO CONTROL

MIN. RECOMMENDED

WIRE GAUGE

Y

Y

DSI CONTROL

1 FLASH

2 FLASH

3 FLASH

STEADY OFF

LED FLASH CODES

COMBUSTION PRESSURE SWITCH OPEN WITH BLOWER ON

COMBUSTION PRESSURE SWITCH CLOSED WITH BLOWER OFF

LOCKOUT FROM THREE IGNITION TRIALS

NO CONTROL POWER

LED

BK

BK

GAS VALVE

BR

BL

24V

LINE V

BK

Y

R

BR

L1/IND

COM

X

TRANSFORMER

W

WIRE CONNECTOR

FIELD WIRING

OPTIONAL FACTORY

FACTORY WIRING

WIRING

BK

W1

R

TERMINAL STRIP

POWER APPLIED, CONTROL OKAY

STEADY ON

G

GRD

SCREW

115-208-230/1/60

220-240/1/50

CAPACITOR

(SEE NOTE #6)

BR

BR

SPARK

TRANSFORMER

WIRING CODE

BLACK - BK

BROWN - BR

RED - R

ORANGE - O

YELLOW - Y

GREEN - G

BLUE - BL

PURPLE - PR

WHITE - W

Y

W1

R

SET ANT

. A

T 0.6 AMPS.

R

W

.R.

1C30-341 THERMOST

AT

O

Y

W

R

PS1

PS2

MV

IND

BK

SYSTEM

BK

W

BK

C

BR

BR

G

G

LOCKOUT FROM FIVE PRESSURE SWITCH LOSSES

CONTROL HARDWARE FAULT DETECTED

LOCKOUT FROM FIVE FLAME LOSSES

6 FLASH

5 FLASH

4 FLASH

G

COMBUSTION

G

BR

OPERATING SEQUENCE

1. SET THERMOSTAT AT LOWEST SETTING.

2. TURN ON MANUAL GAS VALVE.

3. TURN ON POWER TO UNIT.

4. SET THERMOSTAT AT DESIRED SETTING.

5. THERMOSTAT CALLS FOR HEAT, ENERGIZING THE BLOWER MOTOR.

6. COMBUSTION PRESSURE SWITCH CLOSES, FIRING UNIT AT FULL

7. WHEN BURNER FLAME IS SENSED, UNIT CONTINUES FIRING AT FULL RATE.

8. IF THE FLAME IS EXTINGUISHED FIVE TIMES DURING A CALL FOR HEAT,

THE INTEGRATED CONTROL SYSTEM CLOSES THE GAS VALVE AND

MUST BE RESET BY SETTING THE THERMOSTAT AT LOWEST SETTING FOR

(SEE LIGHTING INSTRUCTIONS).

RATE DURING THE IGNITION TRIAL PERIOD.

5 SECONDS, OR INTERRUPTING LINE VOLTAGE FOR 0.25 SECONDS.

NOTES

1. THE FOLLOWING CONTROLS ARE FIELD INSTALLED OPTIONS: THERMOSTAT

2. DOTTED WIRING INSTALLED BY OTHERS.

3. CAUTION: IF ANY OF THE ORIGINAL WIRING AS SUPPLIED WITH THE

APPLIANCE MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL

HAVING A TEMPERATURE RATING OF AT LEAST 105° C. EXCEPT FOR SENSOR

LEAD WIRE, WHICH MUST BE 150° C.

4. USE 18 GA. WIRE FOR ALL WIRING ON THE UNIT.

5. LINE BRANCH WIRE SIZES SHOULD BE OF A SIZE TO PREVENT

VOLTAGE DROPS BEYOND 5% OF SUPPLY LINE VOLTAGE.

6. CAPACITOR IS NOT USED ON 115V MODELS 50-100.

ON 115V. UNITS THE SYSTEM TRANSFORMER IS A SINGLE VOLTAGE PRIMARY.

7. ON 208/230V. UNITS THE SYSTEM TRANSFORMER HAS A DUAL VOLTAGE PRIMARY.

FOR 230V. UNITS, CAP THE 208V TERMINAL.

FOR 208V. UNITS, CAP THE 230V TERMINAL.

8. FOR UNVENTED INSTALLATIONS WHEN MECHANICAL MEANS IS PROVIDED TO

SUPPLY AND EXHAUST, A POSITIVE INTERLOCK MUST BE PROVIDED BY THE

INSTALLER SO THAT THE HEATER CANNOT OPERATE UNLESS THE SUPPLY AND

EXHAUST SYSTEM IS OPERATING.

INTERLOCK SWITCH

(SEE NOTE 8)

CUSTOMER'S