Reznor VR Unit Installation Manual User Manual

Page 20

Form I-VR, P/N 205202 R13, Page 19

Side Shield

Installation

Instructions

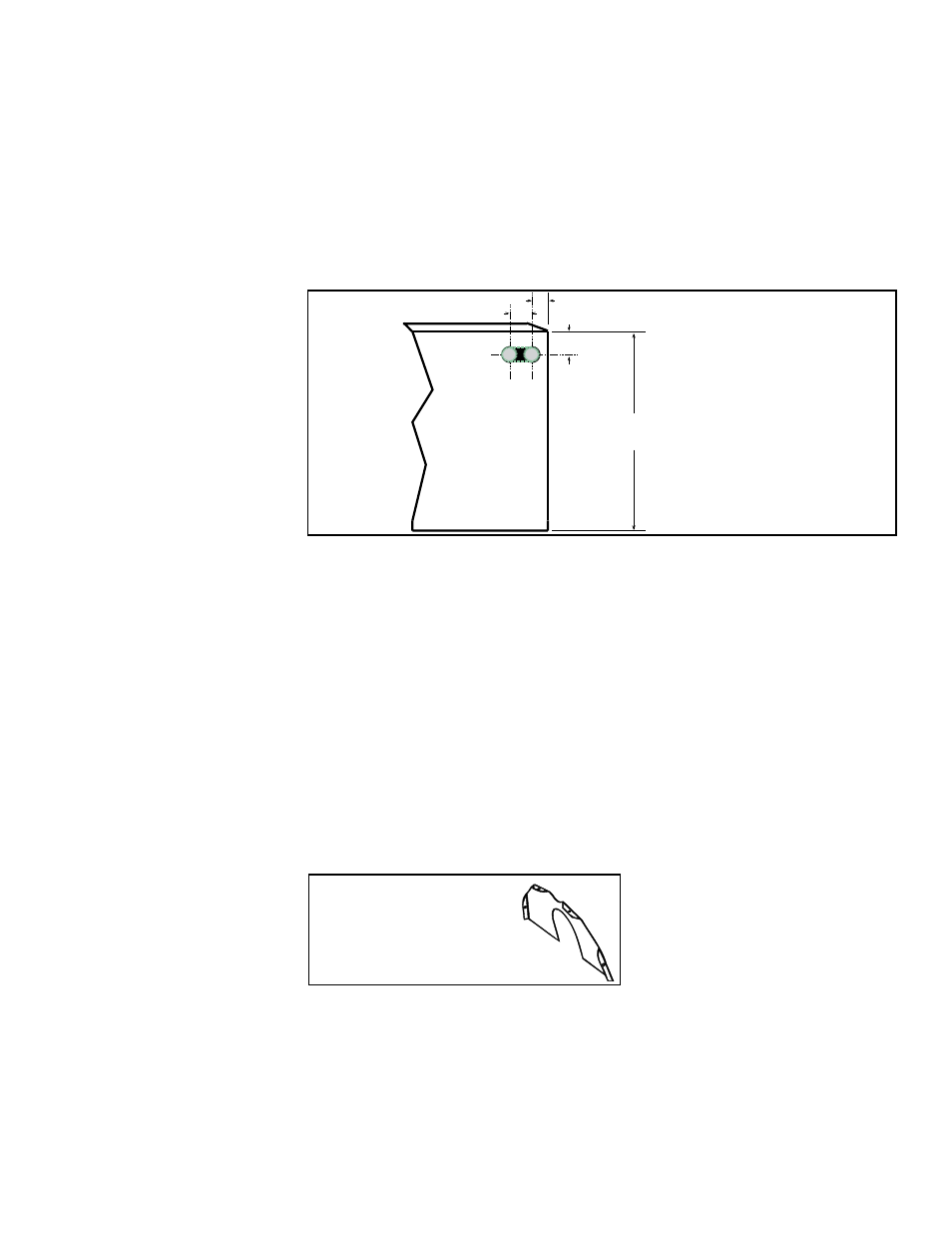

Because side shields can be installed anywhere along the tube length and

use the same wire reflector retainers and tube brackets as the tubes, the side

shield hanger slots must be made in the field to match the system. Therefore,

the first hanger slot location is shown in

FIGURE 20. After the first section is

installed, determine the location of each hanger slot and drill and cut hanger

slots one section at a time.

1) Side shields are designed with a 3/4” (19mm) overlap. On the first sec-

tion, on the top edge with the 60° bend, measure in 3/8” (9.5mm) and 7/8”

(22.2mm) from the end and 21/32” (16.7mm) from the bend. Drill two 5/16”

(8mm) holes. Cut out the material between the two holes to form a slot.

Repeat on the opposite end.

21/32

(16.7mm)

3/8 (9.5mm)

1/2 (12.7mm)

Drill 2 holes,

each 5/16

(8mm) in

diameter,

and cut to

form a slot.

10-15/16

(278mm)

Cut slots

to hang

from the

top

(side of

shield

with the

60° bend)

FIGURE 20 - Drill

2 holes and cut a

slot in each end of

the first side shield

section.

IMPORTANT:

•

Install side shield on one

side of the system only.

•

Maximum reflector angle

with a side shield is 30°.

•

If angled, hang side shield

on lower side only. Do not

hang a side shield on the

higher side.

2) Starting at the already installed reflector retainer/bracket at the burner box

(or wherever the side shield is being placed), determine where the next

side shield hanger is needed. At that location, install one of the wire reflec-

tor retainers and a tube bracket supplied with the side shield. NOTE: Sus-

pension is not required at any of the additional wire reflector retainers and

tube brackets installed to support side shields.

3) Hang the first side shield section from the ends of the two wire reflector

retainers. To secure the side shield, slide the round clip over the ends of

the wire until it contacts the side shield.

4) Repeat the process until all side shield sections are installed. To adapt to

tube suspension points, a side shield may require more than two hanger

slots.

The optional end covers are designed to “close” the vertical space on both the

burner/control box end and the exhaust end of the reflector length.

Install following the illustrated instructions included in the option package.

FIGURE 21 - Optional

Reflector End Cover

(one for each end)

Reflector End Covers,

Option CD27

Reflectors may be angled up to 45°. Angling the reflector is accomplished by

moving the position of the “S” hook on the hanger bar. The hanger bar has

three holes left and right of the center hole. Moving the “S” hook to the first hole

from center will rotate the reflector 15°; the second hole 30°; and the third hole

45°. Refer to

FIGURE 22 and comply with the requirements and instructions

below.

• All reflectors in a system must be at the same angle.

• Reflectors on straight systems without a side shield may be angled 15°,

30°, or 45°; see

FIGURE 22.