3 gas piping and pressures, Mechanical (cont’d) – Reznor VR Unit Installation Manual User Manual

Page 21

Form I-VR, P/N 205202 R13, Page 20

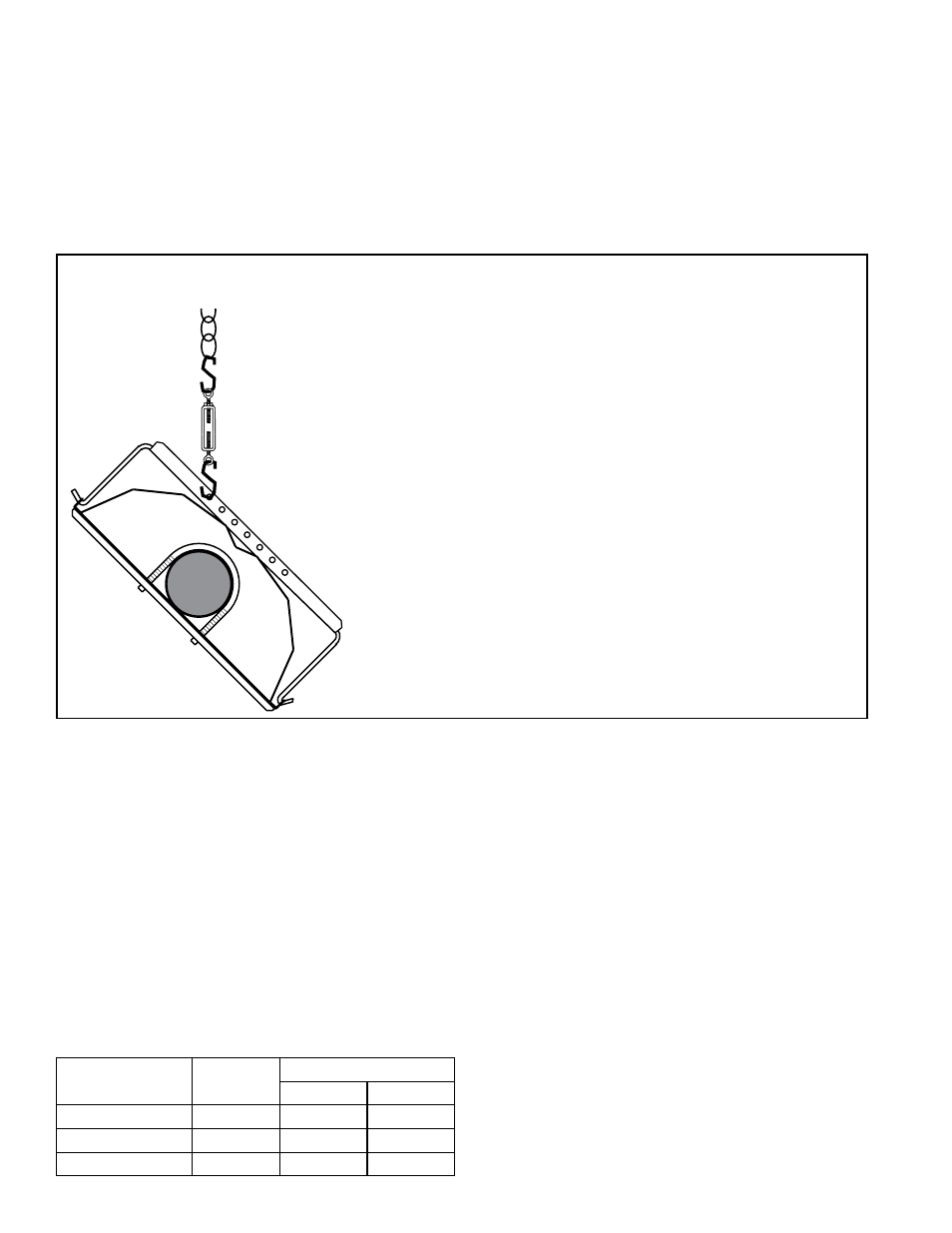

Angle Reflectors on Straight Systems or Angle “U” Configuration Systems

45° Hanging Hole

30° Hanging Hole

15° Hanging Hole

15° Hanging Hole

30° Hanging Hole

45° Hanging Hole

End of wire with sharper 45° bend

must be at the lower side.

Instructions for Angling Reflectors on a

Straight System:

1) If the tube brackets are fastened tightly, loosen

the nuts so that the “U” bolt will rotate with the

wire retainer.

2) Move the “S” hook to another hole in the

hanger bar. The first hole will angle the reflector

15°, the second 30°, and the third 45°. Adjust

chain length as needed.

3) Verify that the end of the wire retainer on the

lower side is the one with the sharper (45°)

bend. If not, remove the retainer wire and

reverse it.

4) Verify compliance with the requirements above.

Tighten the nuts on all tube brackets.

FIGURE 22 - Adjust reflector angle by changing the location of the “S” hook on the

hanger bar.

6.2.5 Recheck

Couplings and Tube

Brackets, Level the

System, Check the

Chains, and Close

“S” Hooks

Verify that all couplings and tube brackets are tightened securely.

Tubes must be level. Use a spirit level and adjust the turnbuckles or chain

links. Chains must be plumb with the suspension point.

Close all “S” hooks being careful not to change the chain length.

Straight systems should be straight; systems with “L” tubes should be at right

angles; and “U” shaped systems should be parallel.

6. Mechanical

(cont’d)

6.2.4 Install Reflectors and Optional Side Shield and/or End

Covers (cont’d)

6.2 Assemble and

Suspend the

Heater (cont’d)

6.3 Gas Piping and

Pressures

All piping must be in accordance with requirements outlined in the National

Fuel Gas Code NFPA 54 / ANSI Z223.1 (latest edition) or CAN/CSA-B149.1

(latest edition). Gas supply piping installation should conform with good prac-

tice and with local codes.

Heaters for natural gas are orificed for operation with gas having a heating

value of 1000 (± 50) BTU per cubic ft. If the gas at the installation does not

meet this specification, consult the factory for proper orifice.

Gas Supply Pressure Table

BTUH Input

Gas Type

Supply Pressure

Minimum Maximum

50,000 - 150,000

Natural

4.5” w.c.

14” w.c.

175,000 - 200,000

Natural

6” w.c.

14” w.c.

50,000 - 200,000

Propane

11” w.c.

14” w.c.

• Reflectors on straight systems with a side shield may be angled 15° or 30°.

The side shield must hang vertically.

• Reflectors on “U” systems without a side shield may be angled 15°, 30° or

45° or 15° or 30° with a side shield. Follow option installation instructions.

• If the system includes an “L” heat exchanger tube, the reflectors cannot be

angled.

The gas supply must have sufficient pressure to

supply the burner plus any other gas-fired appli-

ances. Gas supply pressures required (measured

with a manometer) are listed in the table on the

left.