2 roof curb packages for model series rpb and rpbl, Blower cabinet model rbl, Inside of curb) – Reznor ADFH Option - Installation - Roof Curbs Assembly User Manual

Page 25: Components of roof curb packages, Hardware shipped with the roof curb

Form I-OPT-C, P/N 132900 R17, Page 25

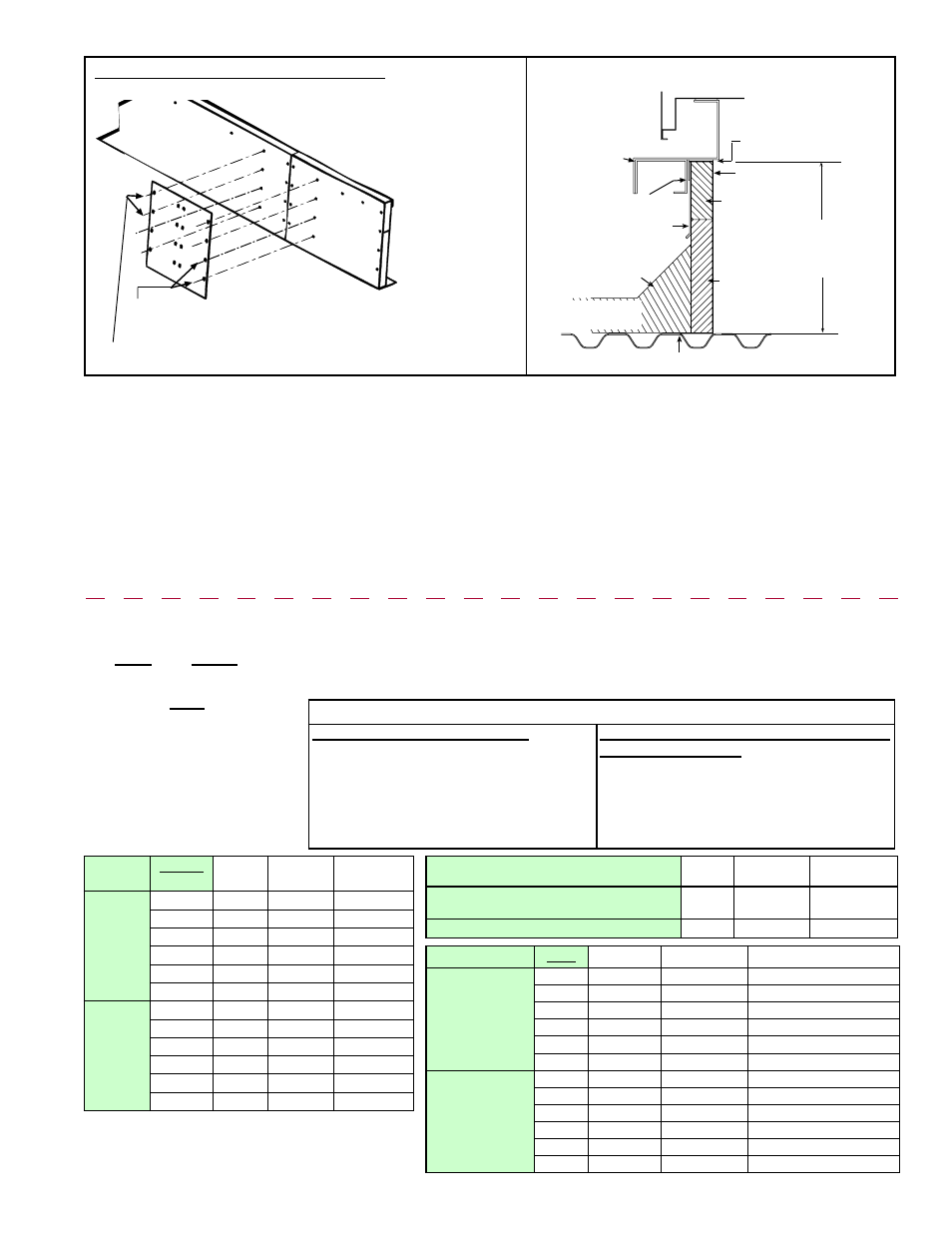

For top 4 holes (2 on each side) at both joints, from inside the curb

insert (4) 5/16 x 1 lag screws and (4) 5/16 lockwashers.

For bottom 4 holes (2 on each side) at both joints, from

outside of the curb insert (4) 5/16-18 x 3/4 long cap screws.

Attach with 5/16 lockwashers and 5/16-18 hex nuts.

(Inside

of Curb)

Curb Cap

Counter Flashing

(by installer)

Cant Strip

(by installer)

MUST be sealed

between curb cap

and roof curb

2 x 6

Wood

Nailer

Insulation

16

(406 mm)

Curb Height

Cabinet

Curb Cap Skirt

Weld, bolt, or lag screw curb to deck structure.

Roof Curb

Curb Cap

Extension

(AHCA, and

AHDA only)

Roofing Felts

(by others)

FIGURE 8B - Curb and Curb Cap Detail

FIGURE 8A (cont'd) - Splicing Detail

(Splicing is

required when the curb sections are two piece.)

COMPONENTS of Roof Curb Packages

Roof curb option selection depends on downturn and/or cooling coil cabinet options

selected with the heating system or blower cabinet. Roof curb option packages include

assembly hardware and four or six factory-assembled curb pieces. Installation hard-

ware and supplies are field-supplied.

5.2 Roof Curb Packages

for Model Series

RPB and RPBL and

Blower Cabinet

Model RBL -

Follow the roof

curb installation

instructions in

Paragraph 5.1.

If there are two side pieces to a side, fasten them with splice plates and hardware as illustrated in the splicing detail

drawing in

FIGURE 8A. Join the corners as illustrated in the corner detail.

3. Check the assembly for squareness. The curb must be adjusted so that the diagonal measurements are equal

within a tolerance of ±1/8” (±3mm).

4. Level the roof curb. To ensure a good weatherproof seal between the unit curb cap and the roof curb, the roof curb

must be leveled in both directions with no twist end to end. Shim as required and secure curb to roof deck before

proceeding with flashing.

5. Install field-supplied flashing.

6. Before placing the unit into position, apply furnished 1/4” x 1-1/4” foam sealant tape to the top surface of the curb,

making good butt joints at corners. The unit must be sealed to the curb to prevent water leakage into the curb area

due to blown rain and capillary action.

Roof Curb Option for Model RBL Blower

Cabinet

Pkg P/N

Curb Side

Assy

Curb Front &

Back Assy

CJ1 - standard cabinet with horizontal

discharge

111944

(2)111940

(2)104657

CJ2 - with downturn plenum AQ5 or AQ8

111381

(2)111385

(2)104657

Roof Curb

Option

for RPB

Series *

Pkg

P/N

Curb Side

Assy

Curb Front &

Back Assy

CJ1 -

blower

and heater

only

125

105215 (2)105221

(2)104652

150, 175

105216 (2)105221

(2)104653

200, 225

105217 (2)105221

(2)104654

250, 300

105218 (2)105221

(2)104655

350

105219 (2)105221

(2)104656

400

105220 (2)105221

(2)104657

CJ2 - with

downturn

plenum

AQ5 or

AQ8

125

104673 (2)104649

(2)104652

150, 175

104674 (2)104649

(2)104653

200, 225

104675 (2)104649

(2)104654

250, 300

104676 (2)104649

(2)104655

350

104677 (2)104649

(2)104656

400

104678 (2)104649

(2)104657

Roof Curb Option

RPBL

Pkg P/N

Curb Side Assy Curb Front & Back Assy

CJ1 - blower and

heater only

400

107251

(2)107257

(2)104657

500, 600

107252

(2)107258

(2)104655

700

107253

(2)107258

(2)104656

800

107254

(2)107258

(2)104657

1050

107255

(2)107259

(2)104656

1200

107256

(2)107259

(2)104657

CJ2 - with

downturn plenum

AQ5 or AQ8

400

107270

(2)107256

(2)104657

500, 600

107271

(2)107257

(2)104655

700

107272

(2)107257

(2)104656

800

107273

(2)107257

(2)104657

1050

107274

(2)107258

(2)104656

1200

107275

(2)107258

(2)104657

*Also applies to these Models with prefix “H”.

Hardware Shipped with the Roof Curb

Corner Hardware & Sealant Tape:

(8) P/N 16247, Cap Screw 5/16"-18x3/4" lg;

(8) P/N 1035, Hex Nut 5/16" - 18;

(8) P/N 16243, Lag Screw 5/16"x1" lg;

(16) P/N 1333, Lockwasher 5/16";

(1) P/N 66302, 1/4"x1-1/4"x50' Sealant Tape

Splicing Plate & Hardware (for curbs with 4

curb side assemblies:

(2) P/N 107260, Splice Plate;

(4) P/N 16243, Lag Screw 5/16"x1" lg;

(16) P/N 1333, Lockwasher 5/16";

(12) P/N 16247, Cap Screw 5/16"-18x3/4" lg;

(12) P/N 1035, Hex Nut 5/16" - 18

- RCB Option - Installation - Roof Curbs Assembly RDB Option - Installation - Roof Curbs Assembly RDC Option - Installation - Roof Curbs Assembly RDCB Option - Installation - Roof Curbs Assembly RDCC Option - Installation - Roof Curbs Assembly RDDB Option - Installation - Roof Curbs Assembly RCC Option - Installation - Roof Curbs Assembly RDDC Option - Installation - Roof Curbs Assembly RECB Option - Installation - Roof Curbs Assembly RECC Option - Installation - Roof Curbs Assembly REDB Option - Installation - Roof Curbs Assembly REDC Option - Installation - Roof Curbs Assembly RDF Option - Installation - Roof Curbs Assembly RDH Option - Installation - Roof Curbs Assembly REH Option - Installation - Roof Curbs Assembly RHH Option - Installation - Roof Curbs Assembly RXH Option - Installation - Roof Curbs Assembly RPB Option - Installation - Roof Curbs Assembly RPBL Option - Installation - Roof Curbs Assembly RPDBL Option - Installation - Roof Curbs Assembly YDSA Option - Installation - Roof Curbs Assembly YDMA Option - Installation - Roof Curbs Assembly YDHA Option - Installation - Roof Curbs Assembly RBL Option - Installation - Roof Curbs Assembly ADF Option - Installation - Roof Curbs Assembly