Figure 5b - option cj3 roof curb assembly for maps, Iii cabinet d – Reznor ADFH Option - Installation - Roof Curbs Assembly User Manual

Page 15

Form I-OPT-C, P/N 132900 R17, Page 15

4. Return Air Duct Supports - Position the two return air side supports

and the end support as shown in

FIGURES 5A and 5D. Follow STEP

7 in

FIGURE 5B to attach.

5. Check the roof curb for squareness. The curb must be adjusted so

that the diagonal measurements are equal within a tolerance of ± 1/8"

(3mm).

6. Level the roof curb. To ensure a good weatherproof seal between the

cabinet curb cap and the roof curb, the curb must be leveled in both

directions with no twist end to end. Shim as required and secure curb

to the roof deck before installing flashing.

7. Install field-supplied flashing. See FIGURE 5C.

8. If the unit has return air and/or down discharge, insert ductwork into

the duct openings. See ductwork sizes in

FIGURE 5E.

9. Before placing the unit on the curb:

□

If ductwork is being installed from the top, slide the ductwork down into

the discharge and return air openings. See dimensions in

FIGURE 5E.

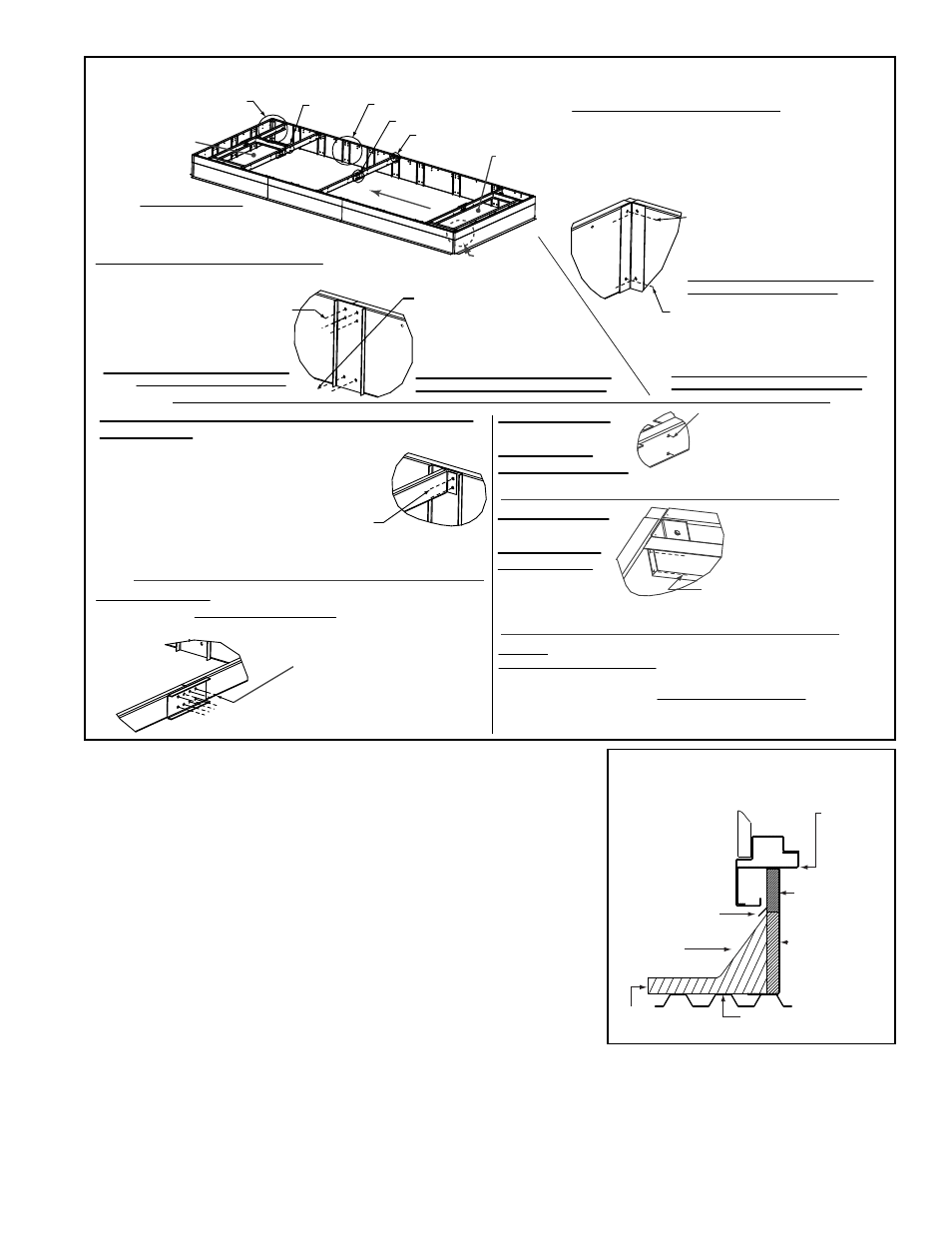

FIGURE 5B - Option CJ3 Roof Curb Assembly for MAPS

®

III Cabinet D

STEP 1 - Detail A - Curb Corner

Position rails as illustrated. If installing Pkg

P/N 220342, be sure to put the two longer

rail side pieces at the return air end.

Position the angle support in the corner and

attach with hardware as illustrated.

Hardware used for 4 Corner Tops:

(8) 2-1/2” Cap Screws, P/N 163334

(8) Lock Washers, P/N 15119

(8) Hex Nuts, P/N 15117

TOP - Cap screw heads should be

on the wood side of the rail.

Hardware used for 4 Corner Bottoms:

(8) 3/4” Cap Screws, P/N 163335

(8) Lock Washers, P/N 15119

(8) Hex Nuts, P/N 15117

BOTTOM - Cap screw heads should

be on the insulation side of the rail.

STEP 2 - Detail B - Rail Side Seam

Connect rail side pieces with the support channels

and hardware as illustrated.

Hardware used for 4 Seams (Top):

(16) 2-1/2” Cap Screws, P/N 163334

(16) Lock Washers, P/N 15119

(16) Hex Nuts, P/N 15117

TOP - Cap screw heads should be

on the wood side of the rail.

Hardware used for

4 Seams (Bottom):

(8) 3/4” Cap Screws, P/N 163335

(8) Lock Washers, P/N 15119

(8) Hex Nuts, P/N 15117

BOTTOM - Cap screw heads should

be on the insulation side of the rail.

STEP 3 - Detail C - Attaching 8 Cross Support Pieces to

the Side Rails (See FIGURE 5D for locations.)

Determine locations of the four cross supports;

dimensions are in FIGURE 5D, page 16

Follow the instructions to attach the ends of all 8

center cross support pieces (4 cross supports;

each with two pieces)

1) Remove the two screws at the

top of the curb rail.

STEP 4 - Detail D - Attaching Splicing Bracket to Connect

Centers of the Four Cross Supports (NOTE: If splice is in a

duct opening, bracket MUST NOT BE INSIDE the opening.)

Hardware for attaching the four

Splicing Brackets:

(32) 3/4” Cap Screws, P/N 163335

(32) Lock Washers, P/N 15119

(32) Hex Nuts, P/N 15117

Curb Assembly

See Dimensions in

FIGURE 5D on page 16.

See Detail A

See

Detail E

See Detail B

See Detail D

See Detail C

STEP 5 - Detail E -

Attaching the Two

Discharge Air

Duct Side Supports

to Curb Cross Supports

See FIGURE 5D; position and

attach the two discharge duct

side supports “inside” the curb

cross supports.

(8) 1/4-20 x 5/8 Bolts, P/N 47252

(8) 1/4-20 Hex Nuts, P/N 7328

Discharge

Duct Opening

Return Air

Opening

STEP 6 - Detail F -

Attaching Two

Return Air Duct

Side Supports

to Curb Rail

(one end of

each support)

See Detail F

(4) 1/4-28 x 2-1/2 Bolt, P/N 114485

(4) Hex Nut 1/4-28, P/N 114486

(4) Lock Washers, P/N 96854

STEP 7

- Repeat Detail E (STEP 5) to attach the opposite ends of the

return air duct side supports (attached in STEP 6) to the cross support.

Repeat Detail E (STEP 5) again to complete the return air duct support

by attaching each end of the return air duct end support to the installed

side supports.

(8) 1/4-20 x 5/8 Bolts, P/N 47252; (8) 1/4-20 Hex Nuts, P/N 7328

2) Position the cross support at the top of the curb as illustrated.

3) Re-insert screws attaching the cross support.

Unit Airflow

Ductwork should be sized slightly smaller with a minimum 3/4" duct flange that can be attached on all sides of the

duct connection. See the system installation manual for ductwork requirements

□

Apply 1/4" x 1-1/4" foam sealant tape to both the top surface of the curb rails and the top surface of the perimeter of

the dividers, being sure to make good butt joints at all corners. The sealant tape must be applied to prevent water

leakage into the curb area due to blown rain and capillary action.

Roofing

Felts (by others)

Cant Strip

(by installer)

Counter Flashing

(by installer)

MUST be

sealed

between

curb cap and

roof curb.

2 x 6

Wood

Nailer

Insulation

Weld, bolt, or lag screw

curb to deck structure.

Curb

Cap

Cabinet W

all

Roof Curb

FIGURE 5C - Cross Section of

Roof Curb Installation

- RCB Option - Installation - Roof Curbs Assembly RDB Option - Installation - Roof Curbs Assembly RDC Option - Installation - Roof Curbs Assembly RDCB Option - Installation - Roof Curbs Assembly RDCC Option - Installation - Roof Curbs Assembly RDDB Option - Installation - Roof Curbs Assembly RCC Option - Installation - Roof Curbs Assembly RDDC Option - Installation - Roof Curbs Assembly RECB Option - Installation - Roof Curbs Assembly RECC Option - Installation - Roof Curbs Assembly REDB Option - Installation - Roof Curbs Assembly REDC Option - Installation - Roof Curbs Assembly RDF Option - Installation - Roof Curbs Assembly RDH Option - Installation - Roof Curbs Assembly REH Option - Installation - Roof Curbs Assembly RHH Option - Installation - Roof Curbs Assembly RXH Option - Installation - Roof Curbs Assembly RPB Option - Installation - Roof Curbs Assembly RPBL Option - Installation - Roof Curbs Assembly RPDBL Option - Installation - Roof Curbs Assembly YDSA Option - Installation - Roof Curbs Assembly YDMA Option - Installation - Roof Curbs Assembly YDHA Option - Installation - Roof Curbs Assembly RBL Option - Installation - Roof Curbs Assembly ADF Option - Installation - Roof Curbs Assembly