Troubleshooting – AERCO BMS II BOILER User Manual

Page 66

TROUBLESHOOTING

5-4

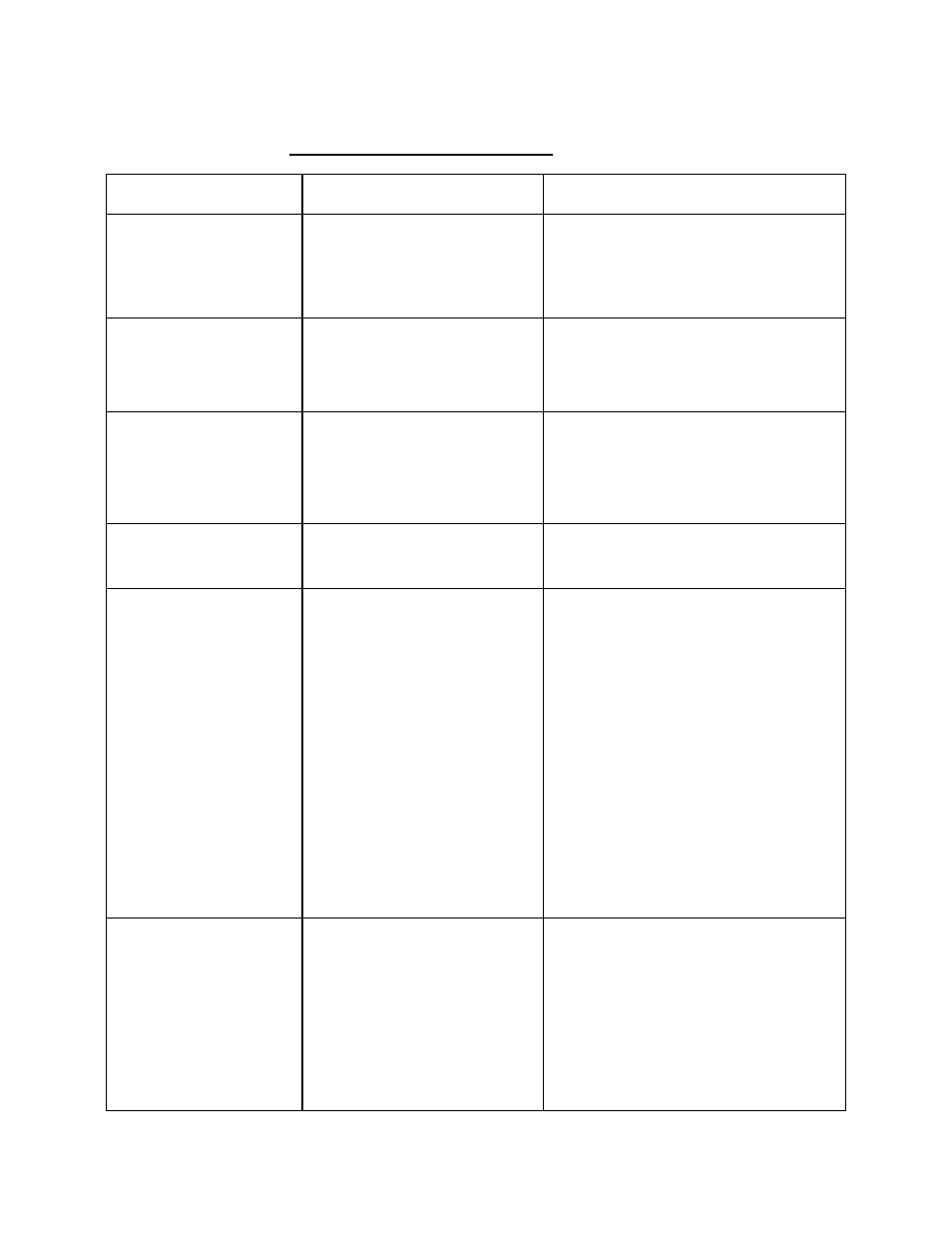

Table 5-2 Common Problems - Continued

Problem

Possible Causes

Solution

EMS cannot see BMSII

• Incorrect address

• Incorrect Baud Rate

• Faulty wiring between EMS

and BMS II.

• See RS232 MENU (paragraph 3.6).

• See RS232 MENU (paragraph 3.6).

• See Chapter 2. Check wiring polarity

and connections.

Boiler RAMP UP or

RAMP DOWN too slow

or too fast

• RAMP UP or RAMP DOWN

time needs adjustment.

• PID requires adjustment.

• Refer to CALIBRATION MENU

(paragraph 3.12) and check the RAMP

UP %/MIN or RAMP DOWN %/MIN

• Refer to TUNING MENU (para. 3.10).

HEADER TEMPERA-

TURE not reaching

Setpoint

• Deadband requires

adjustment

• PID requires adjustment

• Check HDR TEMP DEADBND in

TUNING MENU (paragraph 3.10).

Default = 5°.

• See TUNING MENU (paragraph 3.10).

Need to restore Factory

Default Settings.

• Too many setting changes.

• Go to RESET DEFAULTS option in

CALIBRATION MENU (paragraph

3.12)

Boilers over-shooting

setpoint or tripping

aquastat

• Header sensor not installed

correctly

• PID setting require adjustment

• Adjustable aquastat set too

low

• System pumps are shut down

and not controlled by or

interlocked with the BMS II

• Check header sensor connections and

installation.

• Adjust PID settingsin TUNING MENU

(paragraph 3.10).

• If aquastat is set lower than 200°F,

reset it to 220°F.

• If system pumps are shut down, check

start and stop temperatures on energy

management system. They should

correspond to those set in the BMS II.

In addition, interlock wiring can be run

between the BMS II and energy

management system to disable the

BMS II pumps when pumps are not

running.

Modbus Network faults

encountered. Boiler

plant not operating

• BMS II or boilers not properly

configured for Modbus

communication.

• Bias and/or termination not

activated.

• Refer to Modbus Communication

Manual GF-114 for C-More control or

GF-115-C for BCM control on Modulex

boilers. Check all wiring connections

and software menu settings.

• Activate termination in last boiler.

Activate bias on BMS II for BCM

control or in last C-More control.