Installation, Bms ii – AERCO BMS II BOILER User Manual

Page 28

INSTALLATION

2-16

BMS II

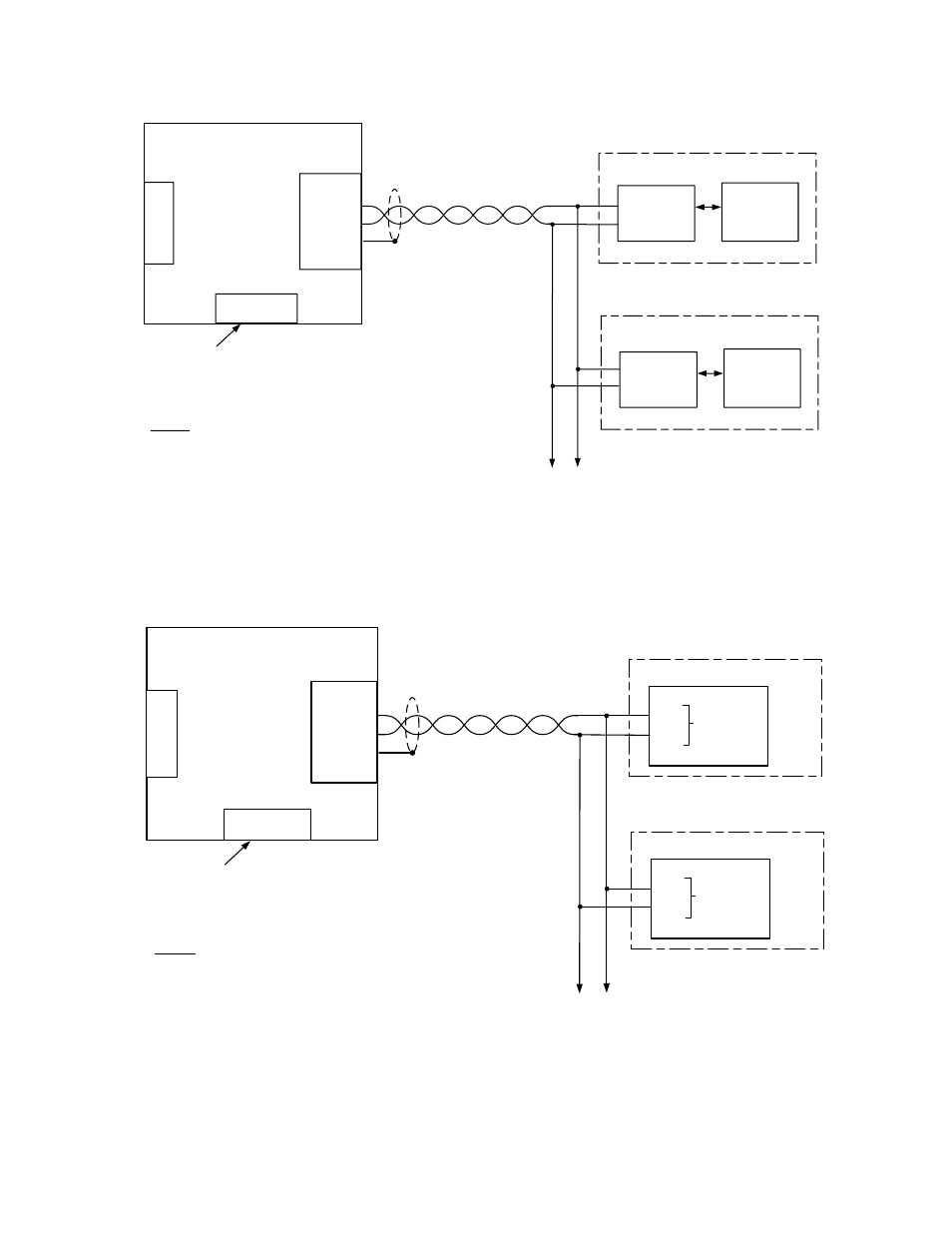

RS

232

PORT

485 B (+)

485 A (-)

SHLD

(TERM. 3)

-

+

RS485

COMM

P/O I/O BOX

C-MORE

SLAVE

NETWORK BOILER 1

-

+

RS485

COMM

P/O I/O BOX

C-MORE

SLAVE

NETWORK BOILER 2

TO OTHER

NETWORK

BOILERS

(3 – 32)

RS

485

PORT

NOTE

THE LAST C-MORE SLAVE ON THE RS485 LOOP

MUST HAVE ITS TERMINATION RESISTOR (TERM)

AND BIAS (BIAS1, BIAS2) DIP SWITCHES TURNED

ON. REFER TO GF-114 MODBUS COMMUNICATION

MANUAL FOR DETAILS.

THE BIAS SWITCHES IN THE BMS II SHOULD BOTH

BE “OFF”

SET BOTH

SWITCHES

TO “OFF”

BIAS

SWITCHES

Figure 2-10. Sample RS485 (Modbus) Network For Benchmark or KC1000 Boilers

BMS II

RS

232

PORT

485 B (+)

485 A (-)

SHLD

(TERM. 3)

TO OTHER

NETWORK

BOILERS

(3 – 9)

RS

485

PORT

NOTE

THE LAST BCM SLAVE ON THE RS485 LOOP MUST

HAVE ITS TERMINATION RESISTOR (T) ACTIVATED.

REFER TO GF-115-C FOR MORE INFORMATION.

THE BIAS SWITCHES IN THE BMS II SHOULD BOTH

BE TURNED “ON”.

SET BOTH

SWITCHES

TO “ON”

BIAS

SWITCHES

B (+)

P/O BCM (Y2)

NETWORK BOILER 1

1

2

A (-)

MODBUS

B (+)

P/O BCM (Y2)

NETWORK BOILER 2

1

2

A (-)

MODBUS

Figure 2-11. Sample RS485 (Modbus) Network For Modulex Series Boilers

- AERClean (12 pages)

- ProtoNode Gateway Rev 1 (with internal LEDs) (64 pages)

- ProtoNode Gateway Rev 3 (with external LEDs) (126 pages)

- Control System (ACS) (144 pages)

- Belimo F6...HD/HDU Series Valve (44 pages)

- Belimo AF120-S US Actuator (9 pages)

- Belimo AMX24-MFT Actuator (9 pages)

- Belimo GKX24-MFT Actuator (9 pages)

- Belimo Motorized Valves Installation (20 pages)

- BMS II BOILER MODBUS Communication (100 pages)

- BMS 168 (86 pages)

- Boiler Valve Controller (BVC) PRIOR to Serial-12-840-1 (35 pages)

- Boiler Valve Controller (BVC) (38 pages)

- Buffer Tanks (14 pages)

- Combination Control Panel (CCP) (4 pages)

- XPC GATEWAY Communications (193 pages)

- Domestic Water Storage Tank (19 pages)

- Steam Traps (6 pages)

- X100 – Inhibitor (4 pages)

- AM Series Boiler User Manual (156 pages)

- AM Series Boiler Cascade Sequencer Controller (26 pages)

- AM Series Boiler Modbus Interface Manual (18 pages)

- BMK 1.5 LN October 2012 (166 pages)

- BMK 1.5 LN July 2011 (152 pages)

- BMK 1.5 LN June 2010 (123 pages)

- BMK 1.5 LN May 2009 (111 pages)

- BMK 1.5 LN Dual Fuel Feb 2013 (162 pages)

- BMK 1.5 LN Dual Fuel June 2010 (139 pages)

- BMK 1.5 LN Dual Fuel Jan 2009 (126 pages)

- BMK 1500-2000 (188 pages)

- BMK 1500DF (196 pages)

- C-More Control Panel (162 pages)

- BMK 2.0 LN October 2012 (172 pages)

- BMK 2.0 LN Natural Gas (SN G-11-1861 and above) (170 pages)

- BMK 2.0 LN Nat. Gas June 2010 (125 pages)

- BMK 2.0 LN Natural Gas 2008 (111 pages)

- BMK 2.0 LN Nat. Gas for Mass. only (113 pages)

- BMK 2.0 LN Dual Fuel Serial G-11-2402 and UP (160 pages)

- BMK 2.0 LN Dual Fuel Nov 2010 (139 pages)

- BMK 2.0 LN Nat. Gas (112 pages)

- BMK 2.0 LN for Mass. only (114 pages)

- BMK 3.0 LN Dual-Fuel Series Gas Fired Low NOx Boiler System (136 pages)

- BMK 3.0 LN Natural Gas July 2011 (129 pages)

- BMK 3.0 LN Nat. Gas Jan 2011 (129 pages)