Checkline TI-MVX User Manual

Page 7

Basic Material Type

If the material velocity is unknown, and a sample thickness cannot be taken from

the material, the user may opt to choose a basic material type from a list with

approximate velocity numbers. It’s important to note that these velocities will not

always be an exact representation of the material being tested. Use these values

only if a close approximation is acceptable. Follow the steps below to select a

basic material type:

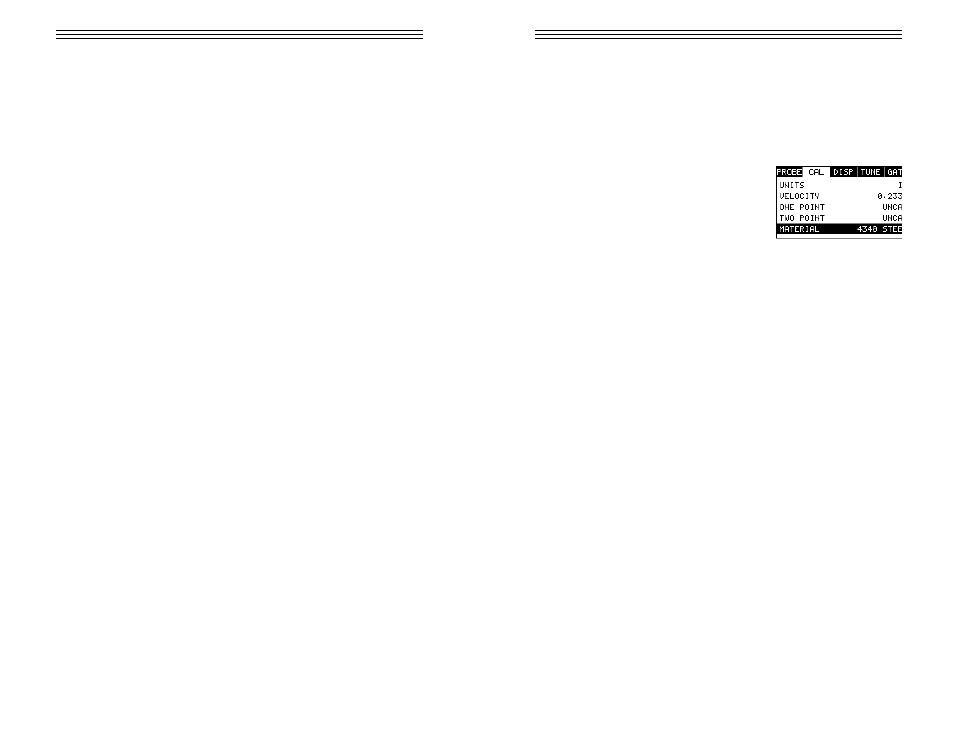

1) Press the MENU key once to activate the

menu items tab. Press the MENU key multiple

times to tab right and the ESC key multiple

times to tab left until the CAL menu is high-

lighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to

scroll through the sub menu items until

MATERIAL is highlighted.

3) Press the ENTER key to display the list of material types.

4) Press the UP and DOWN arrow keys to scroll through the material list until

the appropriate material is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to select the material and return to the menu screen, or

ESC to cancel the material selection.

7) Finally, press the MEAS key to return to the measurement screen and begin

taking readings.

-7-

CHAPTER ELEVEN: SETUPS – CREATE, STORE, EDIT, & RECALL

11.1 Introduction to Setups

Often times, users are faced with a variety of tasks and applications that are

sometimes similar, but often times very different. With a standard thickness

gauge, the user would have to recalibrate for each individual application respec-

tively. With all the features of the TI-MVX, the number of potential applications

also increases based on ability alone. This is primarily in reference to the addi-

tion of those very difficult applications, where a standard thickness gauge would

not be feasible, or capable of accomplishing the tasks.

The increased number of features and parameters also adds to the overall setup

time, or amount of time to set up marginal applications with perfection and

understanding. Because of the additional time involved, the TI-MVX has been

equipped with the ability to save these setups to memory and be recalled at any

time. The TI-MVX can store 64 custom setups. These setups can be bi-direction-

ally transferred to and from a PC. Therefore, the user can save as many setups

as necessary for all of the individual applications. This saves a great deal of time

and knowledge for future inspections of the same job or project. This feature also

eliminates error between two or more users during the setup and calibration

process.

11.2 Opening a Setup

The TI-MVX is loaded with a number of setups from the factory. These setups

can be opened, edited, and saved to any one of 64 setup locations. If a factory

setup is written over, the user can simply reload the default factory setups at

anytime using the utility software included with the TI-MVX. The factory setups

are general setups Only. However, they may serve as an excellent starting point,

requiring only minor adjustments to work for custom applications. It is recom-

mended that user customized setups be saved to an empty location, and save

the factory setups for the purpose of a general starting point. The following pro-

cedures outline how to open factory and custom setups:

-74-