Checkline TI-MVX User Manual

Page 22

0.010 inch to 9.999” in steel. However, the maximum attainable thickness is

much less for more attenuative materials (materials that absorb sound).

Accuracy, is determined by how consistent the sound velocity is through the

sound path being measured and, is a function of the overall thickness of the

material. For example, the velocity in steel is typically within 0.5% while the

velocity in cast iron can vary by 4%.

4.4 Couplant

All ultrasonic applications require some medium to couple the sound from the

transducer to the test piece. Typically a high viscosity liquid is used as the medi-

um. The sound frequencies used in ultrasonic thickness measurement do not

travel through air efficiently. By using a liquid couplant between the transducer

and test piece the amount of ultrasound entering the test piece is much greater.

4.5 Temperature

Temperature has an effect on sound velocity. The higher the temperature, the

slower sound travels in a material. High temperatures can also damage trans-

ducers and present a problem for various liquid couplants.

Since the sound velocity varies with temperature it is important to calibrate at the

same temperature as the material being measured.

Normal temperature range: Most standard transducers will operate from

0

∞

F to 180

∞

F.

High temperature measurements: Special transducers and couplants are

available for temperatures above 180

∞

F up to 650

∞

F with intermittent contact. It

is necessary to cool the transducer, by submerging the transducer in water

between readings, when measuring high temperatures.

Modes and temperature errors: In addition to errors caused by velocity chang-

ing with temperature, some modes (measurement techniques) are affected more

than others. For example, dual element mode has larger errors due to changes

in temperature of the delay line. However, multi-echo techniques help to mini-

mize these errors.

-22-

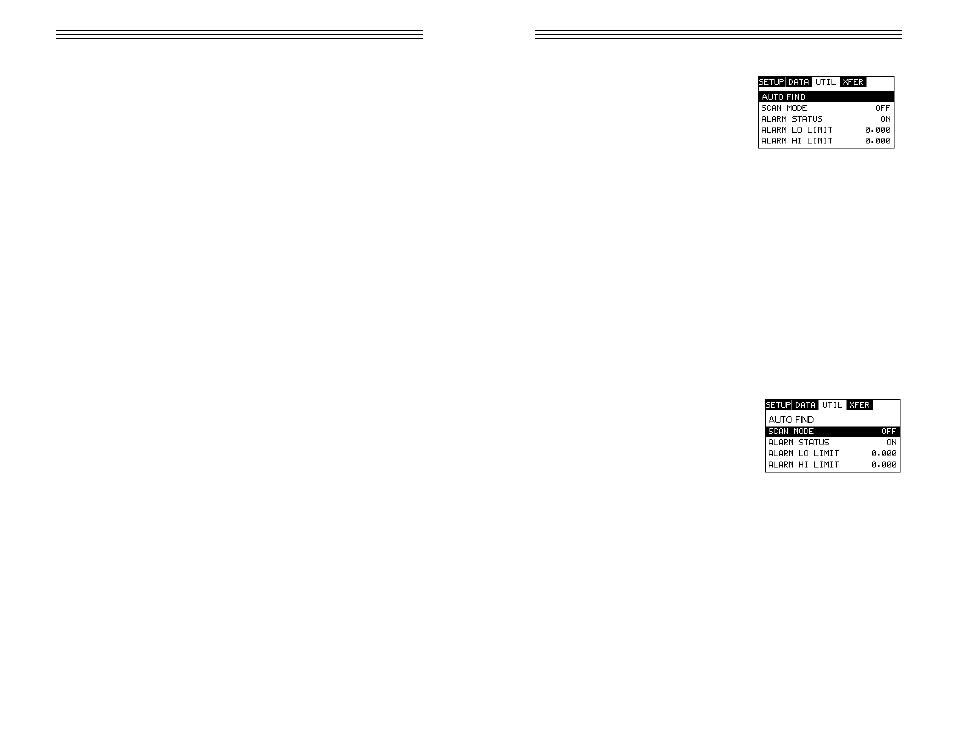

Using Auto Find

1) Press the MENU key once to activate

the menu items tab. Press the MENU key

multiple times to tab right, and the ESC key

multiple times to tab left, until the UTIL

menu is highlighted and displaying the

submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items until

AUTO FIND is highlighted.

3) Place the transducer on the test material and obtain a reading.

4) Press the ENTER key to automatically adjust the display settings and bring

the waveform into view.

5) Once the signal is displayed, press the MEAS key to return to measurement

mode.

9.3

High Speed Scan

The High Speed Scan feature of the TI-MVX increases the overall sample rate

from the standard 4 measurements a second to 32 measurements a second.

This feature enables a user to make scanned passes over an arbitrary length of

the test material, while still maintaining a reasonable representation of thickness

over the scanned area or region. The display will continue to be updated during

the scan process, and when the transducer is removed, the TI-MVX will display

the minimum reading found. The procedure to use the SCAN MODE feature is

outlined below:

Using the Scan Mode

1) Press the MENU key once to activate

the menu items tab. Press the MENU key

multiple times to tab right and the ESC key

multiple times to tab left until the UTIL

menu is highlighted and displaying the sub-

menu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items until

SCAN MODE is highlighted.

3) Use the LEFT and RIGHT arrow keys to toggle the SCAN MODE on/off.

4) Press the MEAS key to return to the measurement screen.

-59-