Checkline TI-MVX User Manual

Page 32

6.2 Probe

Zero

As noted in chapter 3, the probe zero function is a very important and necessary

function that must done prior to calibration. It should also be done on a regular

basis. If the TI-MVX is not zeroed correctly, all of the measurements taken, may

be in error by some fixed value. In order to perform a probe zero, the TI-MVX

must be in pulse-echo mode. If echo-echo mode was previously selected in the

last section, skip this section and continue on to the next. Note: If you intend to

switch between measurement modes simultaneously, temporarily select the

pulse-echo mode using the hot menu option, perform the probe zero function,

and switch back to echo-echo measurement mode after zeroing. The following

steps outline the procedure for performing a probe zero:

Performing a Probe Zero

1) Clean the surface of the Probe Zero

Disk, located on top of the TI-MVX

(battery cover).

2) Apply a drop of couplant to the end of

the transducer, or probe disk, and hold

the transducer in steady contact with the

reference disk.

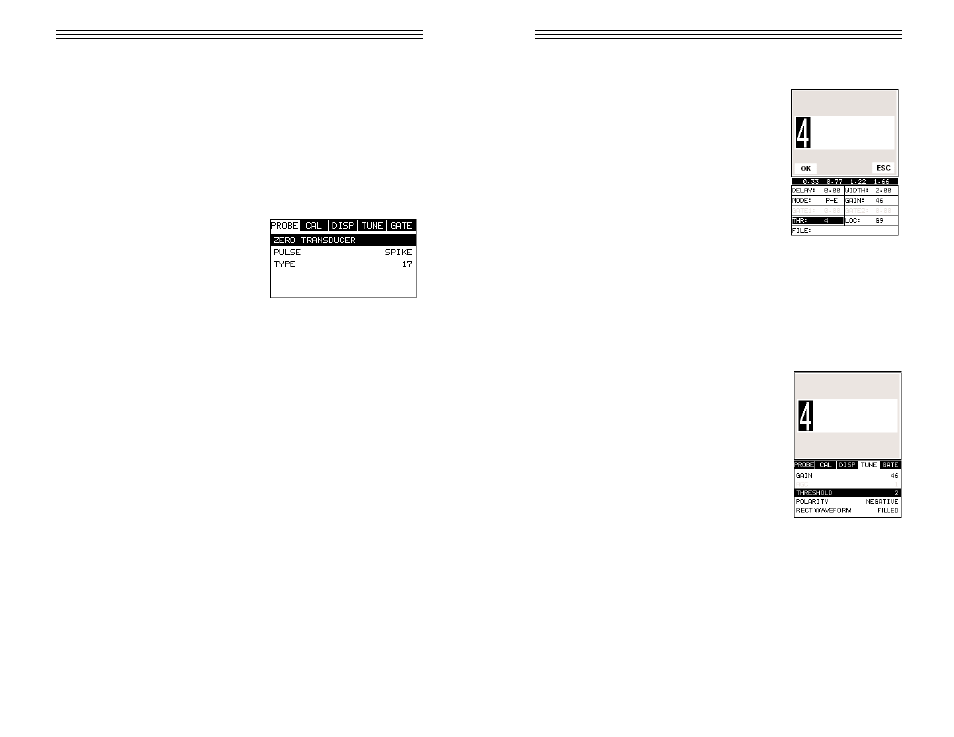

3) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until the

PROBE menu is highlighted and displaying the submenu items.

4) Use the UP and DOWN arrow keys to scroll through the sub menu items until

ZERO TRANSDUCER is highlighted.

5) Press the ENTER key to display the confirmation screen.

6) Press the OK key to zero the transducer and return to the menu screen, or

ESC to cancel the zeroing process.

7) Remove the transducer from the probe zero disk.

8) Press the MEAS key to return to the measurement screen.

6.3 Material

Calibration

In order for the TI-MVX to make accurate measurements, it must be set to the

correct sound velocity of the material being measured. Different types of materi-

als have different inherent sound velocities. For example, the velocity of sound

through steel is about 0.233 inches per microsecond, versus that of aluminum,

which is about 0.248 inches per microsecond. If the gauge is not set to the cor-

rect sound velocity, all of the measurements the gauge makes will be erroneous

by some fixed percentage.

-32-

Adjusting the Threshold using the Hot Menus

1) Press the MEAS key once to activate measure

menu items. Press the MEAS key multiple times

to move right and the ESC key multiple times to

move left, until the THR (threshold) cell is high-

lighted.

2) Press the UP, DOWN, LEFT, and RIGHT

arrow keys to scroll the highlighted value.

3) Alternatively, press the ENTER key to display

the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll

the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the THR value is correctly displayed.

7) Press the OK key to return to the measurement screen, or ESC to cancel

entering the THR.

The user can also access and adjust the Threshold from the tabbed menus.

However, this method is more tedious than making the adjustments using the

Hot Menus. The procedure using the tabbed menus is outlined below:

Adjusting the Threshold using the Tabbed Menus

1) Press the MENU key once to activate the menu

items tab. Press the MENU key multiple times to tab

right, and the ESC key multiple times to tab left,

until the TUNE menu is highlighted and displaying

the submenu items.

2) Use the UP and DOWN arrow keys to scroll

through the sub menu items until THRESHOLD is

highlighted.

3) Press the LEFT and RIGHT arrow keys to scroll

the value. When the correct threshold is being dis-

played, proceed to step 8.

4) Alternatively, press the ENTER key to display the

Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

-49-