Checkline TI-MVX User Manual

Page 23

4.6 Measurement

Modes

In this section we will discuss the different measurements modes the TI-MVX is

capable of operating in, the transducers required, and the reasons for using spe-

cific modes:

Pulse-Echo Mode (Flaw & Pit detection): Pulse-echo mode measures from the

initial pulse (sometimes referred to as an artificial zero) to the first echo (reflec-

tion). In this mode, the transducer is placed on a reference disk, located on top

of the TI-MVX, and a key is pressed to establish a zero point for the particular

transducer.

V-path correction: Dual element delay line transducers have two piezoelectric

elements mounted at an angle on one end of the delay line. One element is

used for transmitting sound, while the other element only receives sound. The

two elements and their delay lines are packaged in a single housing but acousti-

cally isolated from each other with a sound barrier. This allows the transducer

the ability to achieve very high sensitivity for detecting small defects. Also, the

surface of the test material does not have to be as flat in order to obtain good

measurements.

Dual element transducers are normally used in

pulse-echo mode for finding defects, and in echo-

echo mode for through coating measurements.

Dual element delay line transducers are usable

over a range of 0.025 inches to 20 inches

depending on the material, frequency,

and diameter.

A limitation of dual element delay-line transducers is the V shaped sound path.

Because the sound travels from one element to another, the time versus thick-

ness relationship is non-linear. Therefore, a correction table in the instruments

software is used to compensate for this error.

-23-

Dual Element Transducer

showing V-path of signal

CHAPTER NINE: ADDITIONAL FEATURES OF THE TI-MVX

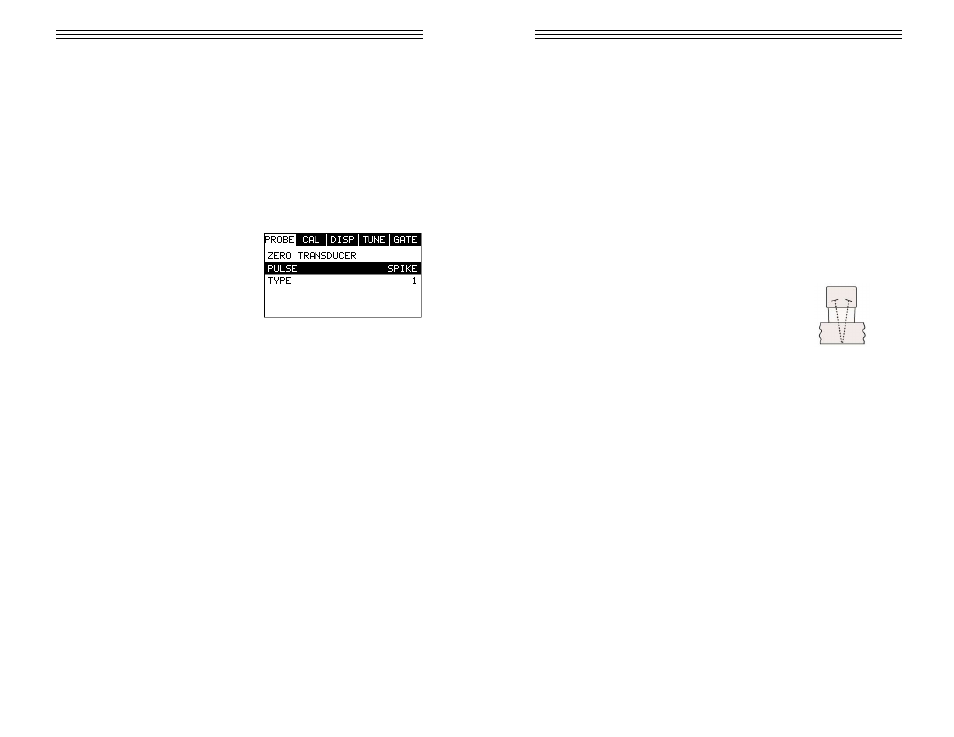

9.1 Pulse

Width

The TI-MVX has an adjustable pulse width option, located as a submenu item in

the PROBE tab group. Pulse width, refers to the duration of time the pulser is left

on. This time results in increased energy sent into the test material. There are

three width options (SPIKE, THIN, and WIDE). The SPIKE setting may be desir-

able for high resolution and general applications to decrease the overall noise.

This can be considered the normal or standard setting. When additional energy

is needed, more penetration, the THIN and WIDE options may be necessary.

The procedure to change the pulse width is outlined below:

Selecting the Pulse Width

1) Press the MENU key once to activate

the menu items tab. Press the MENU

key multiple times to tab right and the

ESC key multiple times to tab left until

the PROBE menu is highlighted and dis-

playing the submenu items.

2) Use the UP and DOWN arrow keys to

scroll through the sub menu items until

PULSE is highlighted.

3) Use the LEFT and RIGHT arrow keys to scroll the Pulse options.

4) Once the Pulse is displayed, press the MEAS key to return to measurement

screen.

9.2 Auto

Find

The TI-MVX is equipped with a very handy feature for locating the detection

point of a back wall echo that is not currently in the viewable region of the dis-

play. Suppose the TI-MVX is currently setup with a delay of 0.0” and a width of

1.0”, and the user is measuring material thickness of 2.5”. The TI-MVX will make

the correct measurement and display it digitally. However, the waveform will not

show up at all in both A-Scan views, and incorrectly in the B-Scan view without

adjusting the range of the Delay and Width accordingly.

The AUTO FIND feature is a convenient way to let the TI-MVX find the detection

point and bring the waveform signal into view automatically. The user can then

make small adjustments to the range once the signal is displayed on the screen.

-58-