Cleaning the filter assembly -25 – Dynojet 250i: Installation Guide User Manual

Page 91

A C C E S S O R I E S

Air Pump and Filter Assembly

Version 5

Model 200i and 250i Motorcycle Dynamometer Installation Guide

3-25

9

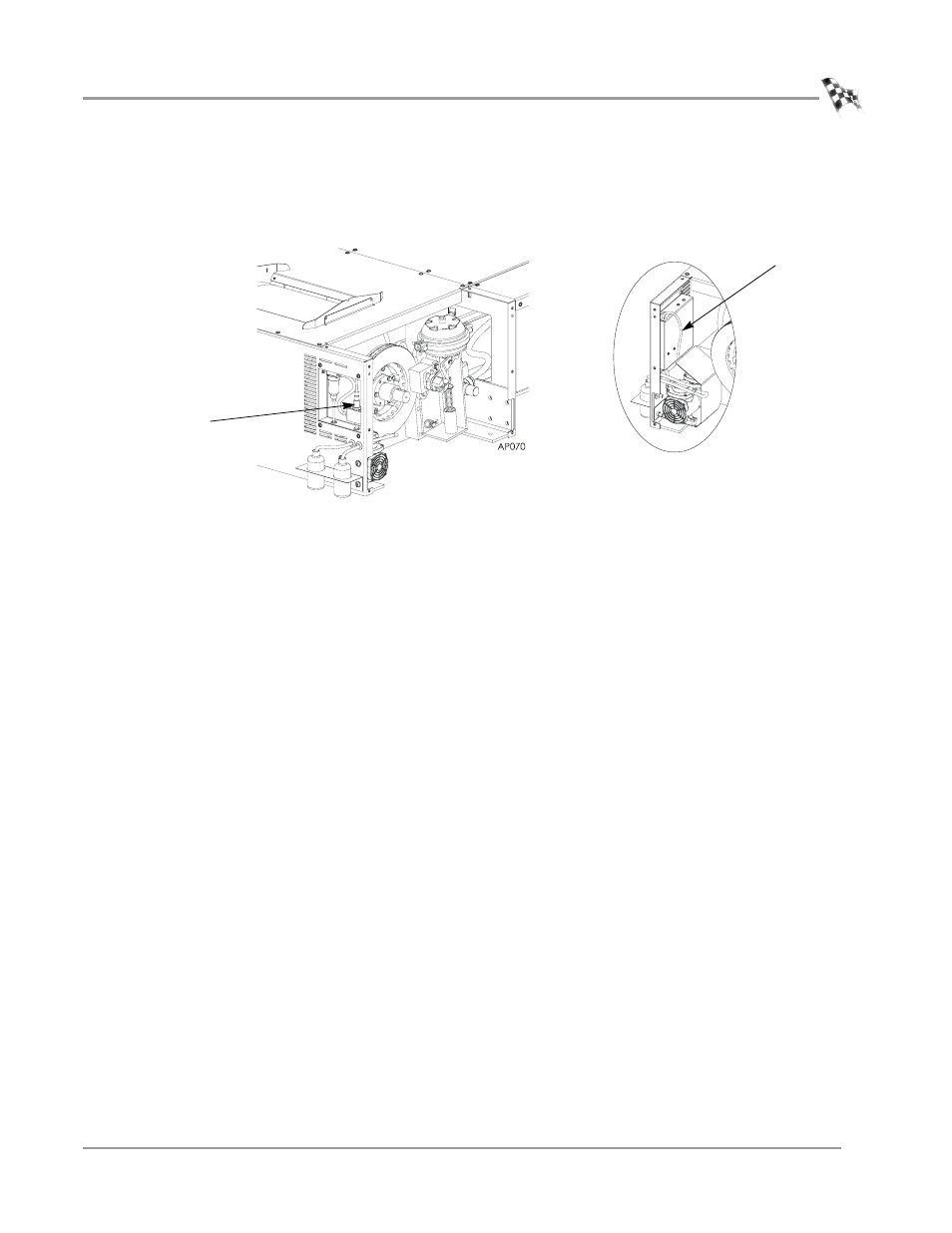

Attach the sensor to the sensor block.

10 Attach the sensor cable to the corresponding cable from the inside back panel of

the dyno.

Figure 3-29: Install the Sensor

11 Locate the wiring harness coming from the switch at the bottom of the filter

assembly. This wiring harness has two connectors. One connector attaches to the

pump while the other attaches to the dyno.

11a Attach the female four-pin connector to the pump cable.

11b Attach the male four-prong connector to the grey cable from the dyno. This

cable is located on the inside back panel of the dyno.

12 Replace the right side drum cover. Refer to “Main Dyno Power” on page 3-2.

C

LEANING

THE

F

ILTER

A

SSEMBLY

Refer to the Air Fuel Ratio Module Installation and User Guide for detailed filter

assembly cleaning procedures. Failure to follow proper procedures may result in

inaccurate data or damage to the equipment. This manual can be found on your

WinPEP CD or at www.dynojet.com.

If cleaning the filter does not result in free air flow, replace the filter. Be sure to check

for other restrictions in the system.

Note: A clogged filter may cause erroneous readings or slow response. Clean the

filter daily or more often depending on usage.

sensor

back view of filter assembly

sensor cable