Connecting the secondary inductive pickup -7 – Dynojet 250i: Installation Guide User Manual

Page 135

B A S I C D Y N O O P E R A T I O N

Connecting the RPM Pickup

Version 5

Model 200i and 250i Motorcycle Dynamometer Installation Guide

5-7

C

ONNECTING

THE

S

ECONDARY

I

NDUCTIVE

P

ICKUP

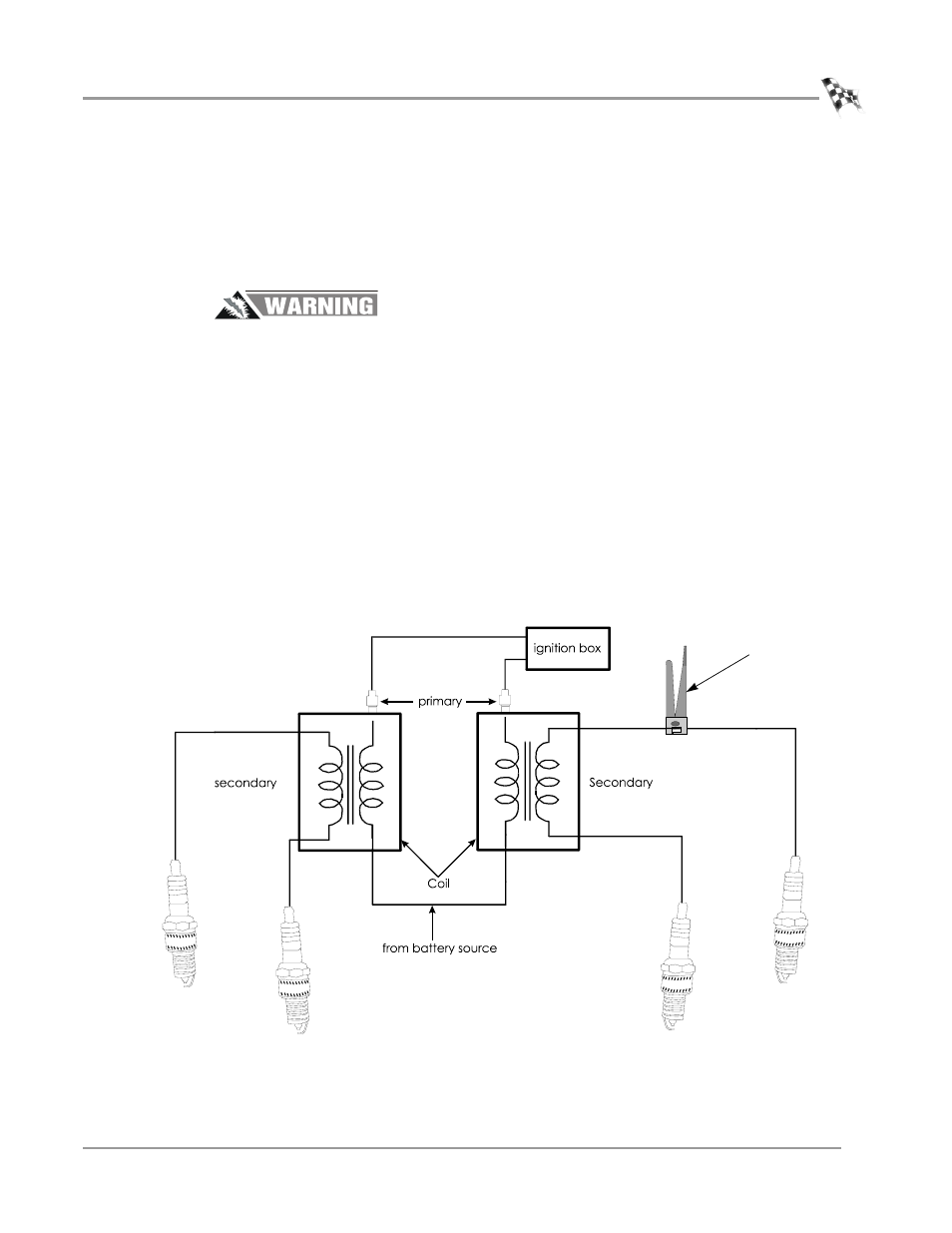

If the primary wire is not accessible connect a secondary inductive pickup to an

available spark plug wire. The secondary inductive pickup cannot be in contact with,

or it’s connecting wire be crossing, other engine electrical wires or stray RF

interference may result.

The inductive pickups contain a fragile Ferrite Core that is sensitive to engine

heat and vibration. Do not drop the inductive pickup or snap the pickup

closed. Use extreme care in handling and placement of the pickups.

1

Clip the secondary inductive pickup around one spark plug wire.

2

Route the inductive pickup cable to the dyno electronics RPM module making

sure the cable is clear of devices that produce electronic noise (spark plug wires,

coil wire, coil etc.).

Note: Inductive pickup placement is important. Position the inductive pickup so

that it is not making contact with any other spark plug wires. Separate the spark

plug wire from the spark plug wire bundle for proper operation.

Note: You must ground the vehicle to the dyno for the electronics to function

properly.

Note: When using one secondary pickup, disconnect the other pickup from the

dyno electronics.

Figure 5-4: Tachometer Pickup Secondary Inductive

connect a secondary

pickup to an available

spark plug wire