Chilled water flow switch, Base board, Fig. 22 — thermistor well – Carrier AQUASNAP MPW015-045 User Manual

Page 39

39

gauge. Pressure readings should be within ± 15 psig. If the

two readings are not reasonably close, replace the pressure

transducer.

Chilled Water Flow Switch —

A factory-installed

flow switch is installed in the leaving fluid piping for all units.

This is a thermal-dispersion flow switch with no field adjust-

ments. The switch is set for approximately 0.5 ft/sec of flow.

The sensor tip houses two thermistors and a heater element.

One thermistor is located in the sensor tip, closest to the flow-

ing fluid. See Fig. 24. This thermistor is used to detect changes

in the flow velocity of the liquid. The second thermistor is

bonded to the cylindrical wall and is affected only by changes

in the temperature of the liquid. The thermistors are positioned

to be in close contact with the wall of the sensor probe and, at

the same time, to be kept separated from each other within the

confines of the probe.

In order to sense flow, it is necessary to heat one of the

thermistors in the probe. When power is applied, the tip of the

probe is heated. As the fluid starts to flow, heat will be carried

away from the sensor tip. Cooling of the first thermistor is a

function of how fast heat is conducted away by the flowing

liquid.

The difference in temperature between the two thermistors

provides a measurement of fluid velocity past the sensor probe.

When fluid velocity is high, more heat will be carried away

from the heated thermistor and the temperature differential will

be small. As fluid velocity decreases, less heat will be taken

from the heated thermistor and there will be an increase in tem-

perature differential.

When unit flow rate is above the minimum flow rate, then

the output is switched on, sending 24 vac to the MBB to prove

flow has been established.

For recommended maintenance, check the sensor tip for

build-up every 6 months. Clean the tip with a soft cloth. If

necessary, build-up (e.g., lime) can be removed with a common

vinegar cleansing agent.

The flow sensor cable is provided with (3) LEDs that indi-

cate if 24 vac power is present and also status of the switch

contacts. The LEDs are as follows:

• Green LED ON – 24 vac present

• One Yellow LED ON – Flow sensor switch OPEN

• Two Yellow LED ON – Flow sensor switch CLOSED

If nuisance trips of the sensor are occurring, follow the

steps below to correct the situation:

1. Check to confirm that the field-installed strainer is clean.

Use the blow-down valve provided or remove the screen

and clean it. For the case of VFD controlled pumps, en-

sure that the minimum speed setting has not been

changed.

2. Measure the pressure drop across the cooler and compare

this to the system requirements.

3. Verify that cable connections at the switch and at the ter-

minal block are secure.

4. Wrong pump motor rotation. Pump must rotate clockwise

when viewed from motor end of pump.

26

25

24

23

22

17

16

15

14

13

12

11

10

9

8

7

6

3

1

3

1

3

1

6

2

4

2

4

2

12

11

21

20

19

18

10

9

8

7

6

5

4

5

4

3

2

1

4

2

1

3

5

BASE

BOARD

J8

SPTA

-

+

DPTA

-

+

A

C

B

A

C

B

RED

GRN

RED

BLK

GRN

RED

BLK

BLU

VIO

LVT

5

4

3

22

23

21

T-55

ACCSY

SEN

OAT ACCESSORY OR

DUAL CHILLER LWT

CONDENSER EWT

ACCESSORY

CONDENSER LWT

ACCESSORY

BLK

RED

COOLER ENTERING

FLUID TEMP

BLK

RED

COOLER LEAVING

FLUID TEMP

RGTA

ACCESSORY

J12

T55

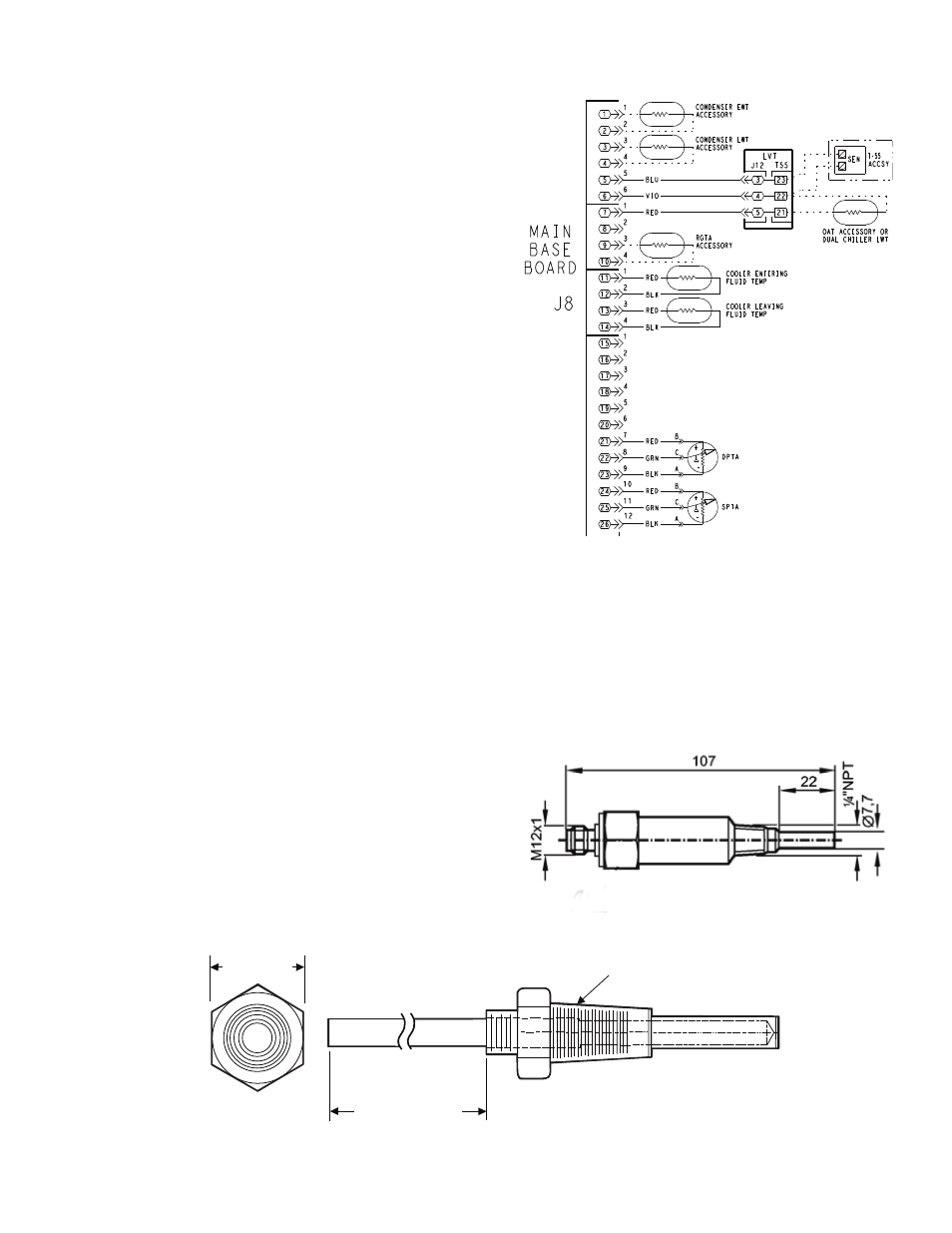

Fig. 23 — Thermistor Connections to

Main Base Board, J8 Connector

LEGEND

ACCSY

— Accessory

DPT

— Discharge Pressure Transducer

EWT

— Entering Water Temperature

LWT

— Leaving Water Temperature Sensor

LVT

— Low Voltage Terminal

OAT

— Outdoor Air Temperature Sensor

RGT

— Return Gas Temperature Sensor

SEN

— Sensor Terminal Block

SPT

— Space Temperature Sensor

a30-5043

Fig. 24— Chilled Water Flow Switch

a30-499

NOTE: Dimensions are in millimeters.

5/8 in. HEX

6" MINIMUM

CLEARANCE FOR

THERMISTOR

REMOVAL

1/4-18 NPT

Fig. 22 — Thermistor Well