Carrier 19DA User Manual

19da, Carrier, Start-up instructions

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Carrier

Start-Up instructions

19DA

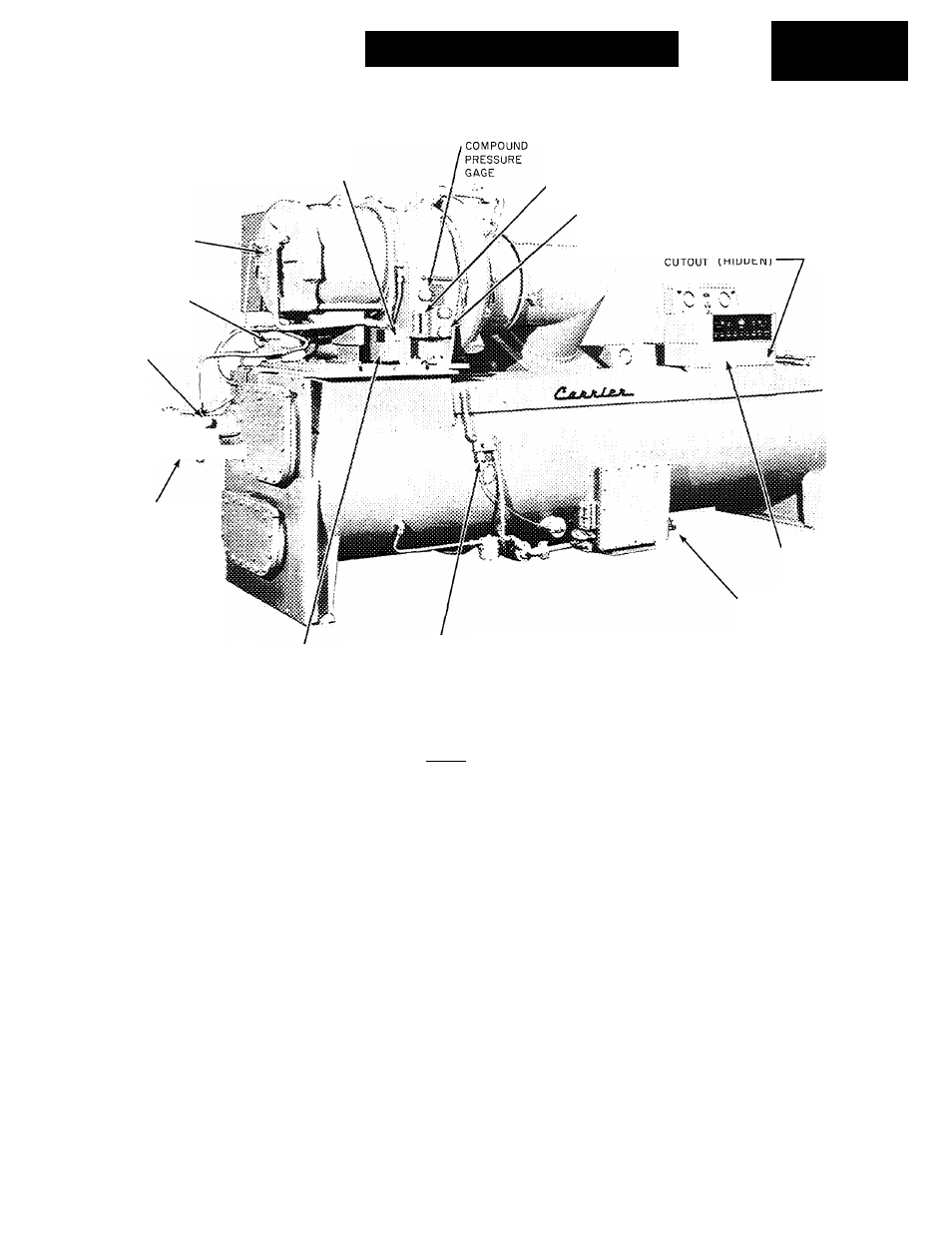

OIL HEATER INDICATOR LIGHT

OSso/c/e. ‘»nd oo /or7^er

S//ó/^/

z^k^/ {do record r) {

dr^'^S fcr /~o ôhiio/ô/e {ak)/o^ ZiÂ* )

MOTOR

ROTATION

SIGHT GLASS

LOW OIL PRESSURE

SWITCH

OIL LEVEL SIGHT GLASS

OIL TEMPERATURE GAGE

CONDENSER HIGH-PRESSURE

OIL PRESSURE

GAGE

OIL CHARGING

VALVE

eX

OIL PUMP

JL,

ASSEMBLY^ --------------------- a

f—?iii;

ANTIRECYCLE

TIMER (HIDDEN)

COOLER

CHARGING

VALVE

OIL THERMOSTAT

(HIDDEN)

REFRIGERANT

LOW TEMP CUTOUT

Fig. 1 - 19DA Hermetic Refrigeration Machine

INTRODUCTION

General

- Use this booklet as a guide for initial

start-up of the 19DA Hermetic Centrifugal Re

frigeration Machine. Read and fully understand

these instructions plus all necessary Job Data

before beginning initial start-up. Instructions are

given in the proper sequence for optimum ma

chine performance.

Job Data Required

1. Machine assembly prints

2. Wiring diagrams

3. Starter details

4. 19DA Installation Instructions

5. 19DA Operation and Maintenance Instructions

Equipment and Materials Required

1. Mechanics' tools

2. Volt-ohmmeter

3. Carrier refrigerant drum charging valve

4. 5/8" SAE X 3/4" MPT cooler charging adapter

5. Five to ten ft of copper tubing or plastic hose

6. Halide or electronic leak detector

7. Low-pressure indicator

a. Absolute pressure manometer

b. Wet-bulb indicator

8. Clamp-on ammeter

9. Portable dehydration pump

INITIAL PREPARATIONS

CAUTION: Do not operate refri^rant pump

unless machine is charged with refrigerant.

Do nor start compressor or oil pump, even for

a rotation check, while machine is at vacuum.

Check rotation only after compressor has been

charged with oil and machine has been charged

with refrigerant.

Machine Tightness

- A shipping vacuum was ap

plied to the refrigerant side of the 19DA machine

before shipment from the factory. Over a period

of time, during shipment or storage, part of this

vacuum may be lost. The loss of a small amount

of vacuum may be acceptable and within Carrier's

machine tightness standards. To determine if the

vacuum loss is acceptable or not requires the

following steps:

© Carrier Corporation 1966

Form 19DA-1SS