Carrier AQUASNAP MPW015-045 User Manual

Page 37

37

The strainers in front of the water/brine inlets of the heat

exchangers should be cleaned periodically, depending on con-

dition of the chiller water/brine.

Oil Charge

Puron refrigerant systems use a polyol ester (POE) oil. Use

only Carrier approved compressor oil. Oil should be visible in

compressor oil sight glass. An acceptable oil level is from

1

/

8

to

3

/

8

of sight glass. All compressors must be off when checking

oil level. Recommended oil level adjustment method is as

follows:

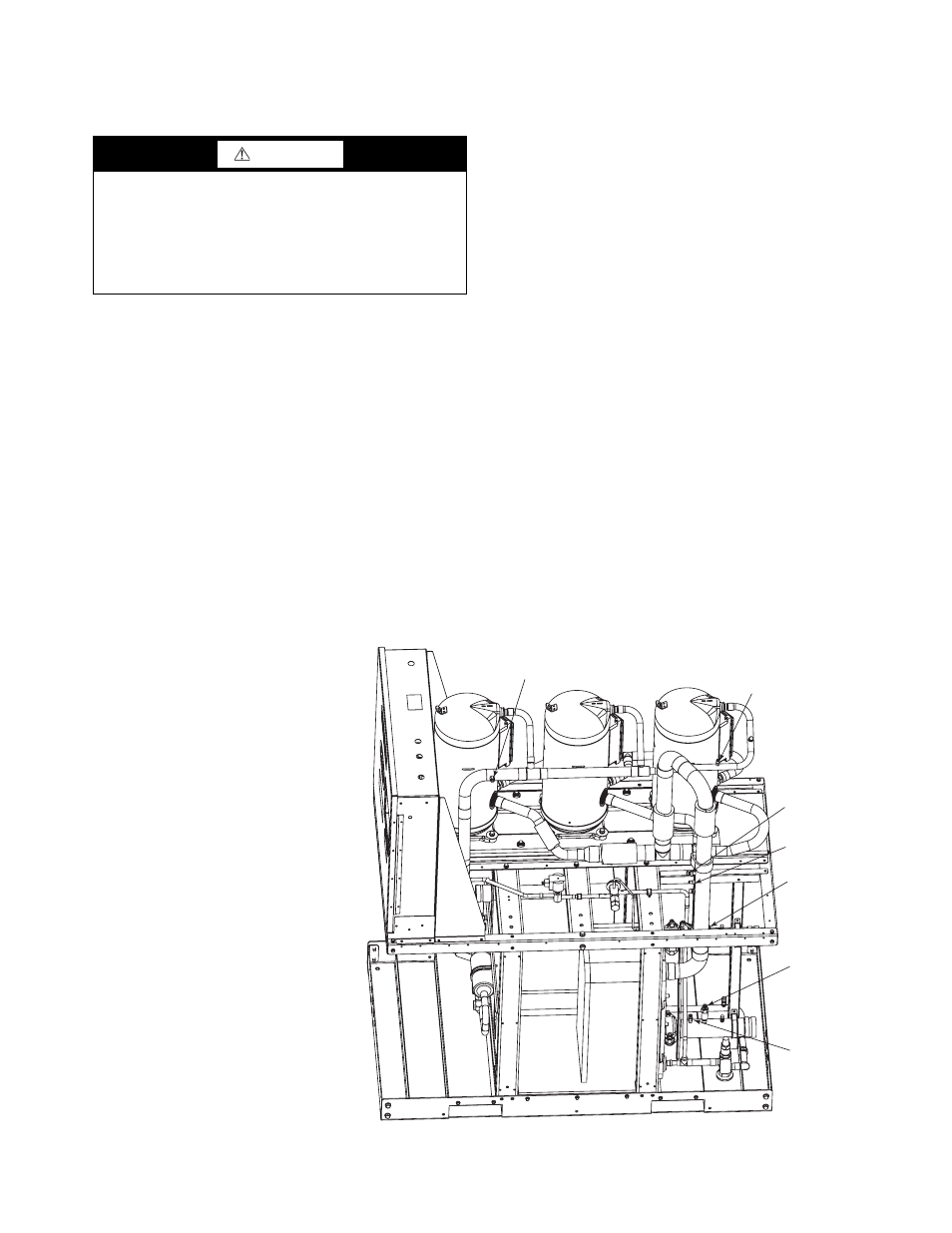

ADD OIL — Recover charge from the unit. Add oil to suction

line Schrader valve on tandem compressors sets and the com-

pressor Schrader on the trios. (See Fig. 21.) When oil can be

seen at the bottom of the sight glass, add oil in 5 oz increments

which is approximately

1

/

8

in oil level. Run all compressors for

20 minutes then shut off to check oil level. Repeat procedure

until acceptable oil level is present.

NOTE: Use only Carrier approved compressor oil. Approved

sources are:

Totaline . . . . . . . . . . . . . . . . . . . . . . 3MAF POE, P903-1601

Mobil. . . . . . . . . . . . . . . . . . . . . . . . . . .EAL Arctic 32-3MA

Uniqema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RL32-3MAF

Do not reuse oil that has been drained out, or oil that has

been exposed to atmosphere.

Check Refrigerant Feed Components

FILTER DRIER — The function of the filter drier is to main-

tain a clean, dry system. The moisture indicator (described

below) indicates any need to change the filter drier. The filter

drier is a sealed-type drier. When the drier needs to be

changed, the entire filter drier must be replaced.

MOISTURE-LIQUID INDICATOR — The indicator is located

immediately ahead of the TXV to provide an indication of the

refrigerant moisture content. It also provides a sight glass for

refrigerant liquid. Clear flow of liquid refrigerant (at full unit

loading) indicates sufficient charge in the system. Bubbles in the

sight glass (at full unit loading) indicate an undercharged system

or the presence of noncondensables. Moisture in the system,

measured in parts per million (ppm), changes the color of the

indicator as follows:

Green (safe) —Moisture is below 75 ppm

Yellow-Green (caution) — 75 to 150 ppm

Yellow (wet) — above 150 ppm

The unit must be in operation at least 12 hours before the

moisture indicator gives an accurate reading, and must be in

contact with liquid refrigerant. At the first sign of moisture in

the system, change the corresponding filter drier.

THERMOSTATIC EXPANSION VALVE (TXV) — The

TXV controls the flow of liquid refrigerant to the cooler by

maintaining constant superheat of vapor leaving the cooler.

The valve(s) is activated by a temperature-sensing bulb(s)

strapped to the suction line(s).

The valve(s) is factory-set to maintain between 8° and 10° F

(4.4° and 5.6° C) of superheat leaving the cooler. Check the

superheat during operation after conditions have stabilized. If

necessary, adjust the superheat to prevent refrigerant floodback

to the compressor.

CAUTION

The compressor in a Puron

®

refigerant (R-410A) system

uses a polyol ester (POE) oil. This is extremely hygro-

scopic, meaning it absorbs water readily. POE oils can

absorb 15 times as much water as other oils designed for

HCFC and CFC refrigerants. Take all necessary precau-

tions to avoid exposure of the oil to the atmosphere. Failure

to do so could result in possible equipment damage.

HPS

DPT

RGT

SPT

EWT

(HIDDEN)

CWFS

LWT

Fig. 21 — Compressor Location — 30MP015-045 Units (30MPW045 Unit Shown)

LEGEND

CWFS

— Chilled Water Flow Switch

DPT

— Discharge Pressure Transducer

EWT

— Entering Water Thermistor

HPS

— High Pressure Switch

LWT

— Leaving Water Thermistor

RGT

— Return Gas Thermistor (Optional)

SPT

— Suction Pressure Transducer

a30-5049