Sensors – Carrier AQUASNAP MPW015-045 User Manual

Page 19

19

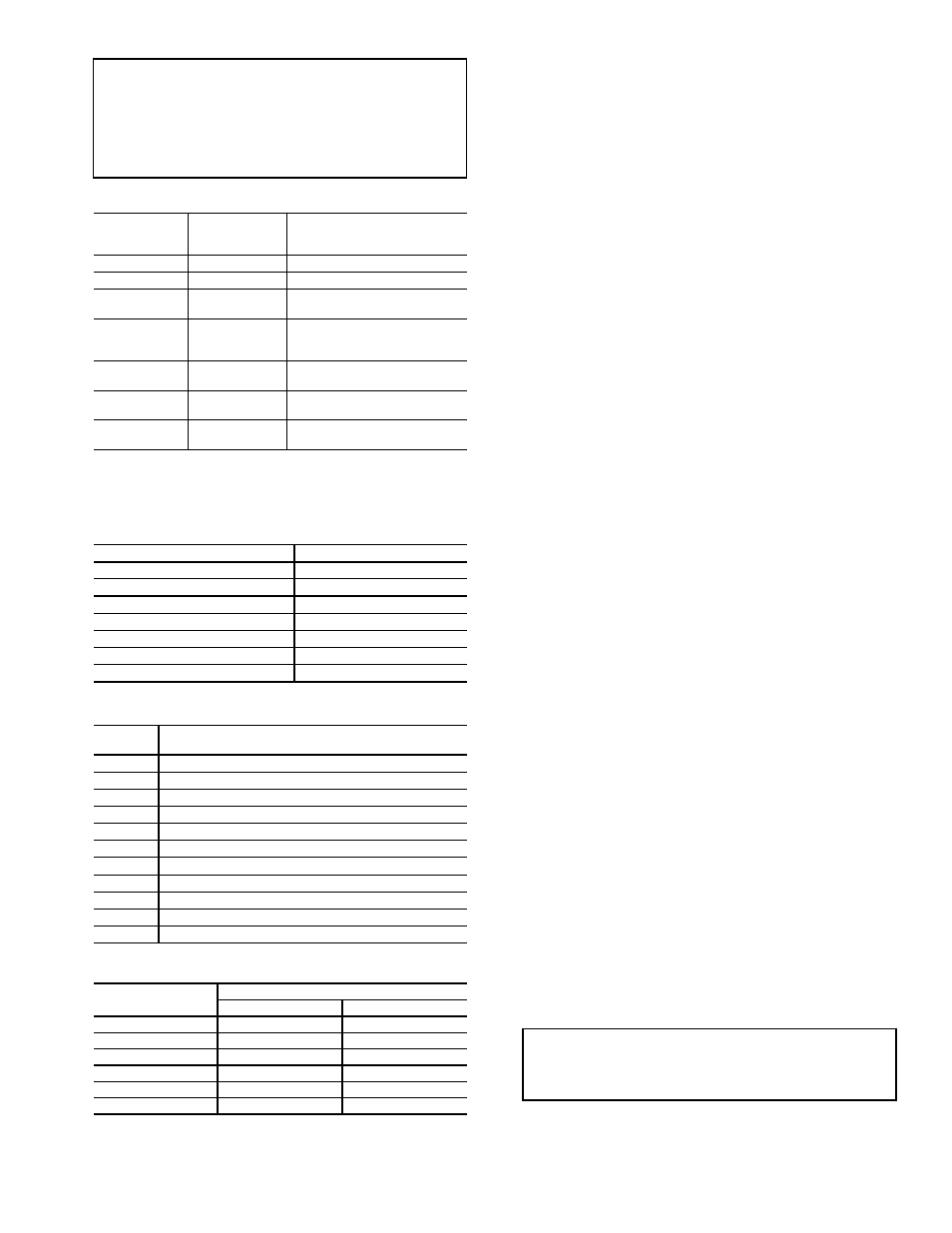

Table 15 — Thermistor Designations

LEGEND

Table 16 — Status Inputs

Table 17 — Output Relays

Table 18 — CCN Communication Bus Wiring

Sensors —

The electronic control uses 2 to 7 thermistors to

sense temperatures for controlling chiller operation. See

Table 15. These sensors are outlined below. Thermistors

RGTA, CNDE, CNDL, EWT, LWT, and OAT are identical in

temperature versus resistance and voltage drop performance.

The dual chiller thermistor (DLWT) is 5 k

at 77 F (25 C)

thermistor. Space temperature thermistor (SPT) is a 10 k

at

77 F (25 C). See Thermistors section for temperature-resis-

tance-voltage drop characteristics.

COOLER LEAVING FLUID SENSOR (LWT) — The thermis-

tor is installed in a well in the factory-installed leaving fluid

piping coming from the bottom of the brazed-plate heat

exchanger.

COOLER ENTERING FLUID SENSOR (EWT) — The therm-

istor is installed in a well in the factory-installed entering fluid

piping coming from the top of the brazed-plate heat exchanger.

CONDENSER LEAVING FLUID SENSOR (CNDL) — The

thermistor is installed in a well in the factory-installed leaving

fluid piping coming from the bottom of the brazed-plate heat

exchanger.

COOLER ENTERING FLUID SENSOR (CNDE) — The therm-

istor is installed in a well in the factory-installed entering fluid

piping coming from the top of the brazed-plate heat exchanger.

COMPRESSOR RETURN GAS TEMPERATURE SEN-

SOR (RGTA) — This accessory thermistor can be installed in

a well located in the suction line.

OUTDOOR-AIR TEMPERATURE SENSOR (OAT) —

This sensor is an accessory that is remotely mounted and used

for outdoor air temperature reset. See Table 15.

DUAL LEAVING WATER TEMPERATURE SENSOR

(DLWT) — This input can be connected to the LVT. See Ta-

ble 15. For dual chiller applications (parallel only are support-

ed), connect the dual chiller leaving fluid temperature sensor

(5 k

thermistor, Carrier part no. HH79NZ029) to the outside

air temperature input of the Master chiller. If outside air tem-

perature is required for reset applications, connect the sensor to

the Slave chiller and configure the slave chiller to broadcast the

value to the Master chiller.

REMOTE SPACE TEMPERATURE SENSOR (SPT) —

The sensor (part no. 33ZCT55SPT) is an accessory sensor that

is remotely mounted in the controlled space and used for space

temperature reset. The sensor should be installed as a wall-

mounted thermostat would be (in the conditioned space where

it will not be subjected to either a cooling or heating source or

direct exposure to sunlight, and 4 to 5 ft above the floor).

Space temperature sensor wires are to be connected to

terminals in the unit main control box. The space temperature

sensor includes a terminal block (SEN) and a RJ11 female

connector. The RJ11 connector is used access into the Carrier

Comfort Network

®

(CCN) at the sensor.

To connect the space temperature sensor (Fig. 8):

1. Using a 20 AWG twisted pair conductor cable rated for

the application, connect 1 wire of the twisted pair to one

SEN terminal and connect the other wire to the other

SEN terminal located under the cover of the space

temperature sensor.

2. Connect the other ends of the wires to terminals 3 and 4

on LVT located in the unit control box.

Units on the CCN can be monitored from the space at the

sensor through the RJ11 connector, if desired. To wire the RJ11

connector into the CCN (Fig. 9):

1. Cut the CCN wire and strip ends of the red (+), white

(ground), and black (–) conductors. (If another wire color

scheme is used, strip ends of appropriate wires.)

IMPORTANT: A shorted CCN bus cable will prevent some

routines from running and may prevent the unit from start-

ing. If abnormal conditions occur, unplug the connector. If

conditions return to normal, check the CCN connector and

cable. Run new cable if necessary. A short in one section of

the bus can cause problems with all system elements on the

bus.

THERMISTOR

PIN

CONNECTION

POINT

THERMISTOR INPUT

CLWT

J8-13,14 (MBB)

Cooler Leaving Fluid

CEWT

J8-11,12 (MBB)

Cooler Entering Fluid

RGTA

J8-9,10 (MBB)

Circuit A Return Gas

Temperature (accessory)

OAT

J8-6,7 (MBB),

LVT 4,13

Outdoor-Air Temperature

Sensor (accessory) or Dual

LWT Sensor

SPT

J8-5,6 (MBB)

LVT-3,4

Accessory Remote Space

Temperature Sensor

CNDE

J8-1,2

Condenser Entering Water

Temperature Sensor

CNDL

J8-3,4

Condenser Leaving Water

Temperature Sensor

LWT — Leaving Water Temperature

MBB — Main Base Board

STATUS SWITCH

PIN CONNECTION POINT

Condenser Flow Switch

LVT-11,17, J7-2, J6-2

Dual Set Point

LVT-12,13, J7-3,4

Remote On/Off

LVT-14,15

Cooler Flow Switch Interlock

LVT-16,17, J6-2, J7-10

Compressor Fault Signal, A1

J9-11,12

Compressor Fault Signal, A2

J9-5,6

Compressor Fault Signal, A3

J9-8,9

RELAY

NO.

DESCRIPTION

K1

Energize Compressor A1

K2

Energize Compressor A2

K3

Energize Compressor A3

K4

Energize Minimum Load Valve

K5

Water Valve Open

K6

Water Valve Close

K7

Liquid Line Solenoid Valve

K8

Crankcase Heater Relay (30MPA Only)

K9

Chilled Water Pump

K10

Condenser Fan/Pump

K11

Alarm Relay

MANUFACTURER

PART NO.

Regular Wiring

Plenum Wiring

Alpha

1895

—

American

A21451

A48301

Belden

8205

884421

Columbia

D6451

—

Manhattan

M13402

M64430

Quabik

6130

—

IMPORTANT: The cable selected for the RJ11 connector

wiring MUST be identical to the CCN communication bus

wire used for the entire network. Refer to Table 18 for

acceptable wiring.