Carrier AQUASNAP MPW015-045 User Manual

Page 34

34

START-UP AND OPERATION

Compressor crankcase heaters must be on for 24 hours be-

fore start-up. To energize the crankcase heaters, close the field

disconnect. Leave the compressor circuit breakers off/open.

The crankcase heaters are now energized.

NOTE: Refer to Start-Up Checklist on pages CL-1 to CL-8.

Actual Start-Up —

Actual start-up should be done only

under supervision of a qualified refrigeration mechanic.

1. Be sure all service valves are open (30MPA units only).

2. Using the scrolling marquee display, set leaving-fluid set

point (Set Points

COOL

CSP.1). No cooling range

adjustment is necessary.

3. Start chilled fluid pump (if not configured for cooler

pump control).

4. Turn ENABLE/OFF/REMOTE CONTACT switch to

ENABLE position.

5. Allow unit to operate and confirm that everything is func-

tioning properly. Check to see that leaving fluid tempera-

ture agrees with leaving set point (Set Points

COOL

CSP.1) or (Set Points

COOL

CSP.2), or if reset is

used, with the control point (Run Status

VIEW

CTPT).

6. Check the cooler leaving chilled water temperature to see

that it remains well above 32 F (0° C), or the brine freez-

ing point if the unit is a medium temperature brine unit.

7. Recheck compressor oil level (see Oil Charge section).

Check Refrigerant Charge —

All 30MPW units are

shipped with a complete operating charge of R-410A and

should be under sufficient pressure to conduct a leak test after

installation. If there is no system pressure, admit nitrogen until

a pressure is observed and then proceed to test for leaks. After

leaks are repaired, the system must be dehydrated.

All refrigerant charging should be done through the ¼-in.

Schraeder connection on the liquid line. Do NOT add refriger-

ant charge through the low-pressure side of the system. If com-

plete charging is required, weigh in the appropriate charge for

the circuit as shown on the unit nameplate. If partial charging is

required, operate circuit at full load and add charge until the

sight glass is clear of bubbles.

The 30MPA units (condenserless) are shipped with a nitro-

gen holding charge only. After chiller assembly is completed in

the field, system must be fully charged. While the unit is run-

ning at full capacity, add refrigerant until the sight glass is clear.

R-410A is the normal refrigerant.

Do not open the liquid valve until there is a charge in re-

mainder of system. A positive pressure indicates a charge in

system. With the unit operating at full load, check liquid line

sight glass to be sure the unit is fully charged (bubbles in the

sight glass indicate the unit is not fully charged).

If there is no refrigerant vapor pressure in the system, the

entire system must be leak tested. After repairing leaks, evacu-

ate the system before recharging.

Follow approved evacuation procedures when removing

refrigeration. Release remaining pressure to an approved evac-

uated cylinder.

The liquid charging method is recommended for complete

charging or when additional charge is required.

EVACUATION AND DEHYDRATION — Because the

30MP systems use polyolester (POE) oil, which can absorb

moisture, it is important to minimize the amount of time that

the system interior is left exposed to the atmosphere. Minimiz-

ing the exposure time of the oil to the atmosphere will mini-

mize the amount of moisture that needs to be removed during

evacuation.

Once all of the piping connections are complete, leak test

the unit and then pull a deep dehydration vacuum. Connect the

vacuum pump to the high flow Schraeder valve in the suction

line and liquid line. For best results, it is recommended that a

vacuum of at least 500 microns (0.5 mm Hg) be obtained. Af-

terwards, to ensure that no moisture is present in the system,

perform a standing vacuum-rise test.

With the unit in deep vacuum (500 microns or less), isolate

the vacuum pump from the system. Observe the rate-of-rise of

the vacuum in the system. If the vacuum rises by more than

50 microns in a 30-minute time period, then continue the dehy-

dration process. Maintain a vacuum on the system until the

standing vacuum requirement is met. This will ensure a dry

system.

By following these evacuation and dehydration procedures,

the amount of moisture present in the system will be mini-

mized. It is required that liquid line filter driers be installed

between the condenser(s) and the expansion devices to capture

any foreign debris and provide additional moisture removal

capacity.

CAUTION

Crankcase heaters on 30MPA units are wired into the con-

trol circuit, so they are always operable as long as the main

power supply disconnect is on (closed), even if any safety

device is open. Compressor heaters must be on for 24

hours prior to the start-up of any compressor. Equipment

damage could result if heaters are not energized for at least

24 hours prior to compressor start-up.

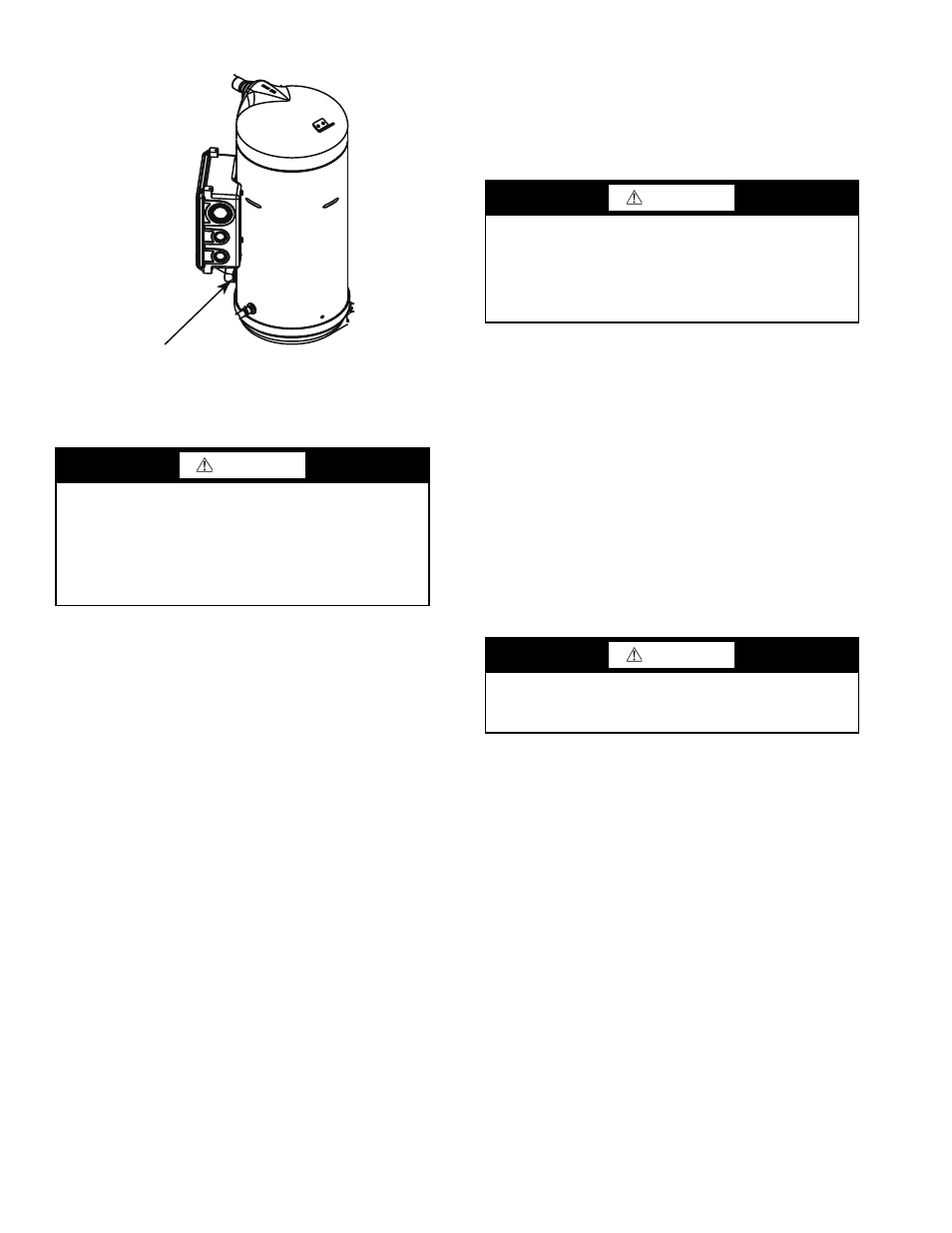

OIL SIGHTGLASS

Fig. 20 — Sight Glass Location

a30-4978

CAUTION

Never charge liquid into low-pressure side of system. Do

not overcharge. Overcharging results in higher discharge

pressure, possible compressor damage, and higher power

consumption. During charging or removal of refrigerant, be

sure water is continuously circulating through the cooler to

prevent freezing.

CAUTION

Be careful not to overcharge the system. Overcharging

results in higher discharge pressure, possible compressor

damage, and higher power consumption.