Carrier AQUASNAP MPW015-045 User Manual

Page 24

24

may be entered for systems with brine solutions, but this value

should be set according to the freeze protection level of the

brine mixture. Failure to properly set this brine freeze point val-

ue may permanently damage the brazed plate heat exchanger.

The control will initiate Mode 7 (Circuit A) to indicate a cir-

cuit’s capacity is limited and that eventually the circuit may

shut down.

Operation of Machine Based on Control

Method and Cooling Set Point Selection Set-

tings —

Machine On/Off control is determined by the

configuration of the Control Method (Configuration

OPT2

CTRL) and Cooling Set Point Select

(Configuration

SLCT

CLSP) variables. All units are fac-

tory configured with Cooling Set Point Select set to 0 (single

set point). With the control method set to 0, simply switching

the Enable/Off/Remote Contact switch to the Enable or

Remote Contact position (external contacts closed) will put the

chiller in an occupied state. The control mode (Run

Status

VIEW

STAT) will be 1 (OFF LOCAL) when the

switch is Off and will be 5 (ON LOCAL) when in the Enable

position or Remote Contact position with external contacts

closed.

Two other control methods are available for Machine On/

Off control:

OCCUPANCY SCHEDULE (Configuration

OPT2

CTRL = 1) — The main base board will use the operating

schedules as defined under the Time Clock mode in the scroll-

ing marquee display. These schedules are identical. The sched-

ule number must be set to 1 for local schedule.

The schedule number can be set anywhere from 65 to 99

for operation under a CCN global schedule. The Enable/Off/

Remote Contact must be in the Enable or Remote Contact posi-

tion. The control mode (Run Status

VIEW

STAT) will be

1 when the switch is Off. The control mode will be 3 when the

Enable/Off/Remote Contact switch input is On and the time of

day is during an unoccupied period. Similarly, the control

mode will be 7 when the time of day is during an occupied

period.

CCN SCHEDULE (Configuration

OPT2

CTRL =

2) — An external CCN device such as Chillervisor System

Manager controls the On/Off state of the machine. This CCN

device forces the variable ‘CHIL_S_S’ between Start/Stop to

control the chiller. The control mode (Run Status

VIEW

STAT) will be 1 when the switch is Off. The con-

trol mode will be 2 when the Enable/Off/Remote Contact

switch input is On and the CHIL_S_S variable is ‘Stop.’

Similarly, the control mode will be 6 when the CHIL_S_S vari-

able is ‘Start.’

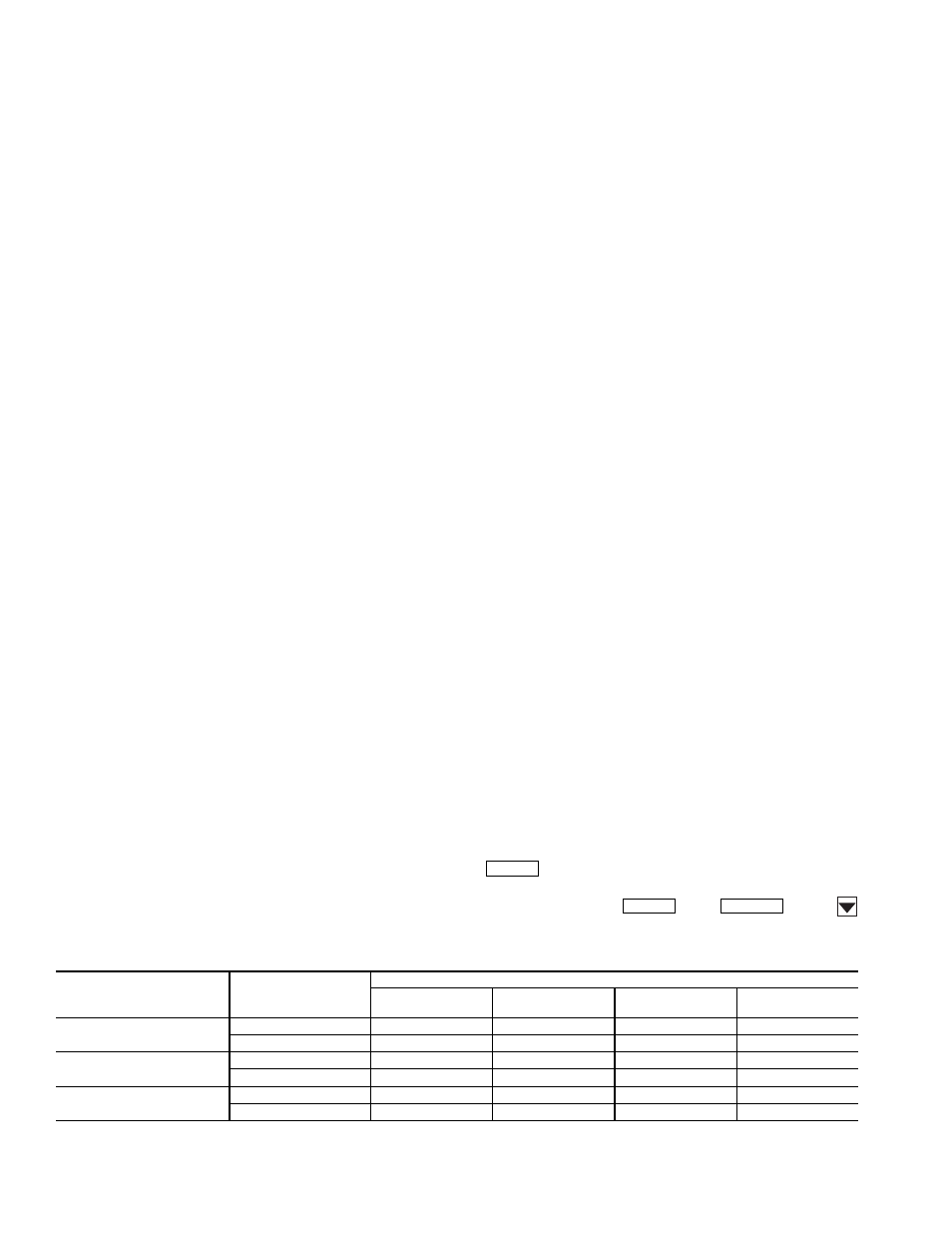

Table 20 illustrates how the control method and cooling set

point select variables direct the operation of the chiller and the

set point to which it controls. The illustration also shows the

ON/OFF state of the machine for the given combinations.

Cooling Set Point Select

SINGLE — Unit operation is based on Cooling Set Point 1

(Set Points

COOL

CSP.1).

DUAL SWITCH — Unit operation is based on Cooling Set

Point 1 (Set Points

COOL

CSP.1) when the Dual Set

Point switch contacts are open and Cooling Set Point 2 (Set

Points

COOL

CSP.2) when they are closed.

DUAL

CCN

OCCUPIED — Unit operation is based on

Cooling Set Point 1 (Set Points

COOL

CSP.1) during the

Occupied mode and Cooling Set Point 2 (Set

Points

COOL

CSP.2) during the Unoccupied mode as

configured under the local occupancy schedule accessible only

from CCN. Schedule Number in Table SCHEDOVR (See Ap-

pendix B) must be configured to 1. If the Schedule Number is

set to 0, the unit will operate in a continuous 24-hr Occupied

mode. Control method must be configured to 0 (switch). See

Table 20.

4 TO 20 mA INPUT — Unit operation is based on an external

4 to 20 mA signal input to the Energy Management Module

(EMM).

Cooler Pump Control —

The AquaSnap® 30MP ma-

chines are configured with the Cooler Pump Control (Configu-

ration

OPT1

CPC) = ON.

The maximum load allowed for the Chilled Water Pump

Starter is 5 VA sealed, 10 VA inrush at 24 volts. The starter coil

is powered from the chiller control system. The starter should

be wired between LVT 24 and TB3-1. If equipped, the field-in-

stalled chilled water pump starter auxiliary contacts should be

connected in series with the chilled water flow switch between

LVT 16 and LVT 17.

Ice Mode —

When Ice Mode is enabled Cooling Setpoint

Select must be set to Dual Switch, Dual 7 day or Dual CCN

Occupied and the Energy Management Module (EMM) must

be installed. Unit operation is based on Cooling Setpoint 1

(CSP.1) during the Occupied mode, Ice Setpoint (CSP.3) dur-

ing the Unoccupied mode with the Ice Done contacts open and

Cooling Setpoint 2 (CSP.2) during the Unoccupied mode with

the Ice Done contacts closed. These 3 set points can be utilized

to develop your specific control strategy.

Service Test (See Table 4) —

Both main power and

control circuit power must be on.

The Service Test function should be used to verify proper

operation of condenser output, compressors, minimum load

valve solenoid (if installed), cooler pump, and remote alarm re-

lay. To use the Service Test mode, the Enable/Off/Remote Con-

tact switch must be in the OFF position. Use the display keys

and Table 4 to enter the mode and display TEST. Press

twice so that OFF flashes. Enter the password if re-

quired. Use either arrow key to change the TEST value to the

ON position and press

. Press

and the

button to enter the OUTS or COMP sub-mode.

Table 20 — Control Methods and Cooling Set Points

*Dual set point switch input used. CSP1 used when switch input is open. CSP2 used when switch input is closed.

†Cooling set point determined from 4 to 20 mA input to energy management module (EMM) to terminals TB6-3,5.

ENTER

ENTER

ESCAPE

CONTROL

TYPE

(CTRL)

OCCUPANCY

STATE

COOLING SET POINT SELECT (CLSP)

0

(single)

1

(dual, switch)

2

(dual, occ)

3

(4 to 20 mA)

0 (switch)

Occupied

ON,CSP1

ON*

ON,CSP1

ON†

Unoccupied

ON,CSP1

ON*

ON,CSP2

ON

2 (Occupancy)

Occupied

ON,CSP1

ON*

Illegal

ON†

Unoccupied

OFF

OFF

Illegal

OFF

3 (CCN)

Occupied

ON,CSP1

ON*

ON,CSP1

ON†

Unoccupied

ON,CSP1

ON*

ON,CSP2

ON†