Pre-start-up, System check – Carrier AQUASNAP MPW015-045 User Manual

Page 33

33

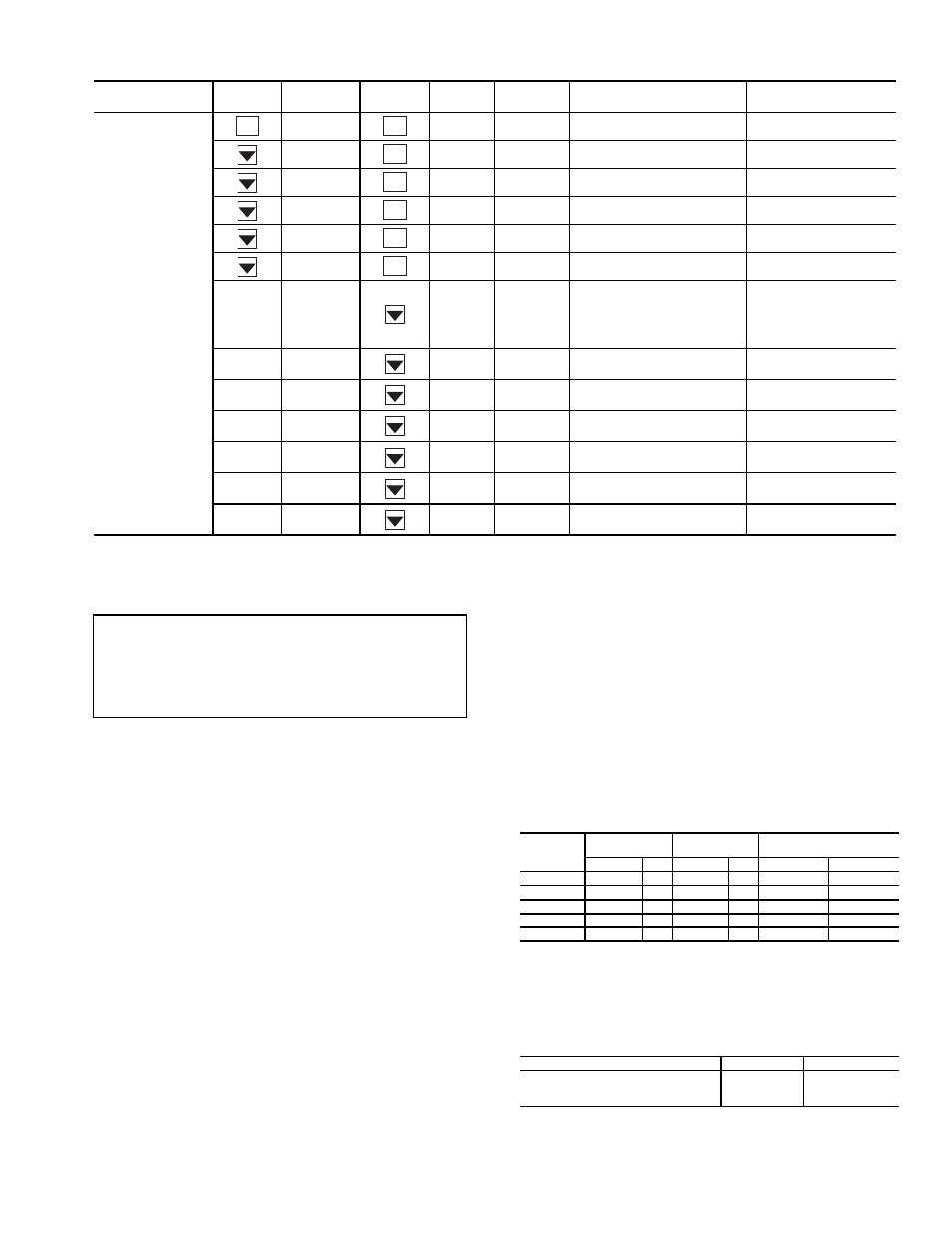

Table 27 — Configuring Demand Limit

*Seven items skipped in this example.

PRE-START-UP

Do not attempt to start the chiller until following checks

have been completed.

System Check

1. Check all auxiliary components, such as chilled fluid

pumps, air-handling equipment, condenser pump or other

equipment to which the chiller supplies liquid. Consult

manufacturer's instructions. Verify that any pump inter-

lock contacts have been properly installed. If the unit has

field-installed accessories, be sure all are properly in-

stalled and wired correctly. Refer to unit wiring diagrams.

2. Use the scrolling marquee display to adjust the Cooling

Set Point.

3. Fill chilled fluid circuit with clean water (with recom-

mended inhibitor added) or other non-corrosive fluid to

be cooled. Bleed all air out of the high points of the sys-

tem. If chilled water is to be maintained at a temperature

below 40 F (4.4 C), a brine of sufficient concentration

must be used to prevent freeze-up at anticipated suction

temperatures. To ensure sufficient loop volume, see

Table 28.

4. Check tightness of all electrical connections.

5. Oil should be visible in the compressor sightglass(es).

See Fig. 20. An acceptable oil level in the compressors is

from

1

/

8

to

3

/

8

of sight glass when the compressors are off.

Adjust the oil level as required. See Oil Charge section on

page 37 for Carrier approved oils.

6. Crankcase heaters must be firmly attached to compres-

sors, and must be on for 24 hours prior to start-up

(30MPA units only).

7. Electrical power source must agree with unit nameplate.

8. Check rotation of scroll compressors. Monitor control

alarms during first compressor start up for reverse rota-

tion protection alarm.

Table 28 — Minimum Flow Rates and Minimum

Loop Volume (for Comfort Cooling)

LEGEND

NOTES:

Gallons = V x AHRI capacity in tons.

Liters = N x AHRI capacity in kW.

MODE

KEYPAD

ENTRY

SUB-MODE

KEYPAD

ENTRY

ITEM

DISPLAY

ITEM EXPANSION

COMMENT

CONFIGURATION

DISP

TEST

ON/OFF

Test Display LEDs

UNIT

TYPE

X

Unit Type

OPT1

FLUD

X

Cooler Fluid

OPT2

CTRL

X

Control Method

CCN

CCNA

X

CCN Address

RSET

CRST

X

Cooling Reset Type

DMDC*

X

Demand Limit Select

Default: 0

0 = None

1 = Switch

2 = 4 to 20 mA Input

3 = CCN Loadshed

DM20

XXX %

Demand Limit at 20 mA

Default: 100%

Range: 0 to 100

SHNM

XXX

Loadshed Group

Number

Default: 0

Range: 0 to 99

SHDL

XXX%

Loadshed Demand

Delta

Default: 0%

Range: 0 to 60%

SHTM

XXX MIN

Maximum Loadshed

Time

Default: 60 min.

Range: 0 to 120 min.

DLS1

XXX %

Demand Limit

Switch 1

Default: 80%

Range: 0 to 100%

DLS2

XXX %

Demand Limit

Switch 2

Default: 50%

Range: 0 to 100%

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

IMPORTANT: Before beginning Pre-Start-Up or Start-Up,

complete Start-Up Checklist for 30MP Liquid Chiller at

end of this publication (page CL-1 to CL-8). The checklist

assures proper start-up of a unit, and provides a record of

unit condition, application requirements, system informa-

tion, and operation at initial start-up.

UNIT SIZE

EVAPORATOR

CONDENSER*

MINIMUM EVAPORATOR

LOOP VOLUME

Gal./Min

L/s

Gal./Min

L/s

Gal.

L

30MP015

22

1.4

22

1.4

46.2

174.9

30MP020

28

1.8

28

1.8

60.9

230.5

30MP030

43

2.7

43

2.7

92.4

349.7

30MP040

55

3.5

55

3.5

78.4

296.7

30MP045

64

4.0

64

4.0

91.6

346.7

AHRI —

Air Conditioning, Heating, and Refrigeration Institute

N

—

Liters per kW

V

—

Gallons per ton

APPLICATION

V

N

Normal Air Conditioning

3

3.25

Process Type Cooling

6 to 10

6.5 to 10.8

Low Ambient Operation

6 to 10

6.5 to 10.8