Great Plains YP1625 Operator Manual User Manual

Page 58

1625

401-182M

7/12/2005

56

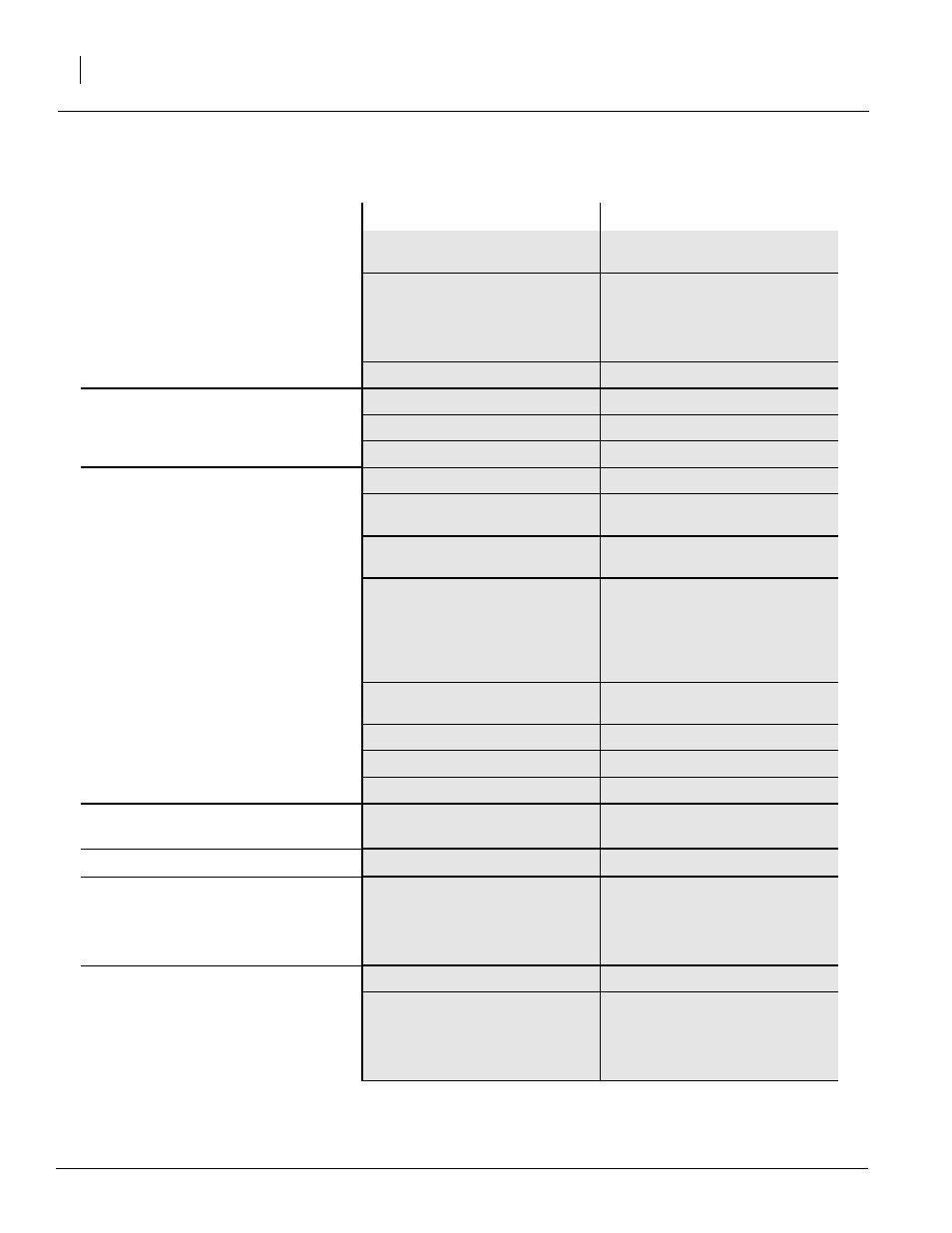

Press wheels not compacting the soil

as desired.

Too wet or cloddy.

Wait until drier weather or rework

ground.

Use of incorrectly shaped tire for

your conditions.

Wedge shaped wheels work best on

narrow spacings and in wet condi-

tions. Round edge wheels work best

in wider row spacings and drier con-

ditions.

Incorrect press wheel depth.

Reset press wheel depth, page 31.

Excessive seed cracking.

Excessive field speed.

Reduce field speed.

Unclean seed.

Use clean seed.

Damaged, old or dry seed.

Use clean, new seed.

Press wheel or row-units plugging

Planting conditions too wet.

Wait until drier weather.

Too much pressure on row-units.

Reduce down pressure on row-

units.

Coulters set too deep, bring up

excess dirt and moisture.

Check coulter adjustment.

Planter not set to run level from front

to rear, carrying enough weight on

gauge wheels to prevent “nosing

over”, or set too low on rear caster

eyebolts allowing it to run “nose

high”.

Check Leveling Frame Front-to-

Rear, page 18.

Backed up with planter in the

ground.

Clean out and check for damage.

Failed disk bearings.

Replace disk bearings.

Disk blades worn.

Replace disk blades.

Scraper worn or damaged.

Replace scraper.

Air lines plugging between air box and

Y splitters

Fan too slow.

Speed up fan.

Seed blowing out of pro-box door area

Fan too fast.

Slow down fan.

Air lines plugging between Y-tube and

meter

Improper air hose routing.

With machine folded the air lines

should be tight. With it unfolded they

should form a gentle horizontal “S”

shape through the holders with no

big sags.

Air lines plugging above air box at fold

area

Fan too slow.

Speed up fan.

Improper air hose routing.

With machine folded the air lines

should be tight. With it unfolded they

should form a gentle horizontal “S”

shape through the holders with no

big sags.

Problem

Cause

Solution