Side gauge wheels – Great Plains YP1625 Operator Manual User Manual

Page 38

1625

401-182M

7/12/2005

36

Side Gauge Wheels for 25 Series Row-Units

Refer to Figure 31

The side gauge wheels have two, interrelated

adjustments:

• angle of side gauge wheel, and

• distance between side gauge wheel and row

unit disk.

Refer to Figure 32

Adjust side-gauge-wheel angle so the wheels

contact the row unit disks between 4 and 8 o’clock

at the bottom of wheel.

At the same time, keep the side gauge wheels

close to the row-unit disks so row-units do not

plug with soil or trash but far enough out so the

disks and wheels turn freely.

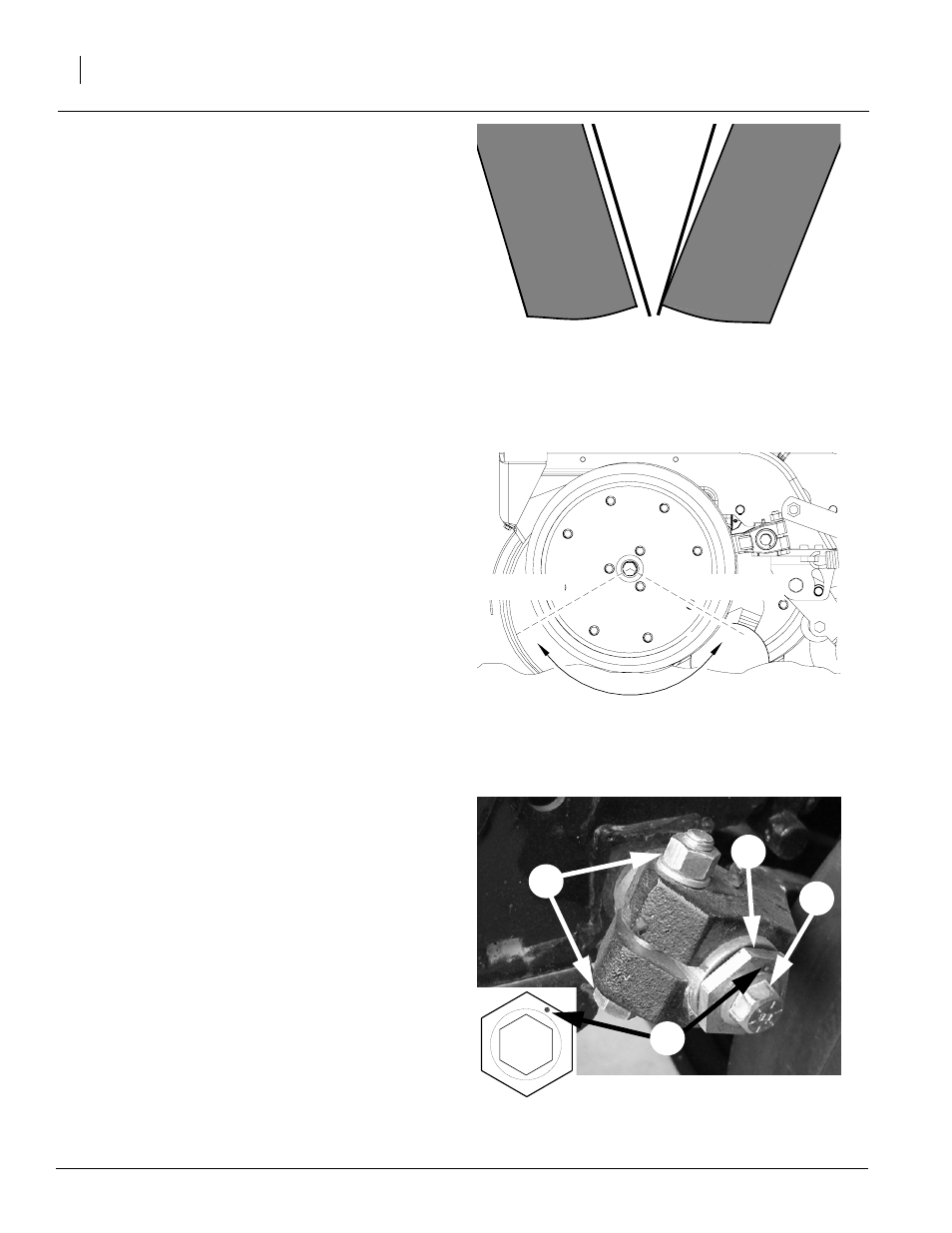

Refer to Figure 33

To adjust side gauge wheels:

1.

Raise planter slightly to remove weight from

side gauge wheels.

2.

Loosen hex-head bolt (1). Move wheel and

arm out on o-ring bushing.

3.

Loosen pivot bolt (2). Turn hex adjuster (3) so

roll pin (4) is at 1 o’clock. Use this as the start-

ing point for adjustment.

4.

Move wheel arm in so side gauge wheel con-

tacts row unit disk. Tighten hex-head bolt (1)

to clamp arm around bushing and shank.

5.

Check the wheel-to-disk contact. Lift wheel

and arm. When let go, the wheel should fall

freely.

• If wheel does not contact disk from 4 to 8

o’clock, move hex adjuster until wheel is an-

gled for proper contact with disk.

• If wheel does not fall freely, loosen hex-

head bolt (1) and slide wheel arm out just until

wheel and arm move freely. Retighten hex-

head bolt.

6.

Keep turning hex adjuster and moving wheel

arm until the wheel is adjusted properly.

When satisfied, tighten pivot bolt to 110 foot-

pounds. Tighten pivot bolt (2).

Side Gauge

Wheel

Side Gauge

Wheel

Row-Unit

Disks

Incorrect

Correct

Figure 31

Side Gauge Wheels

17812

Figure 32

Wheel-to-Disk Contact Area

8 o’clock

4 o’clock

Figure 33

Side Gauge Wheel Adjustment

Starting Point

18450

2

1

3

4

Note: Wheel touches at bottom and gaps open 3/8” to

5/8” at top.