Great Plains YP1625 Operator Manual User Manual

Page 57

7/12/2005

401-182M

55

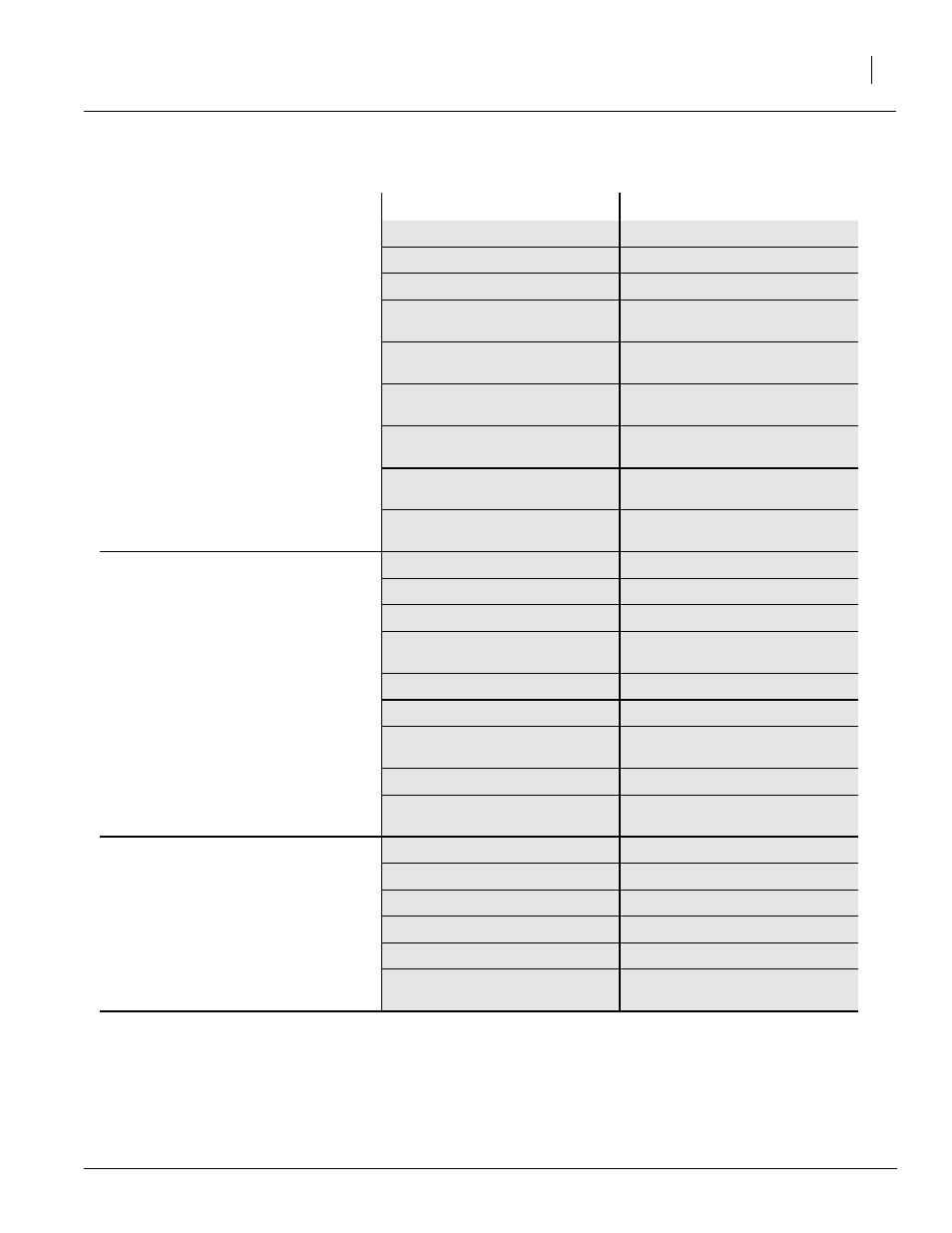

Troubleshooting

Uneven seed spacing.

Excessive field speed.

Reduce field speed.

Unclean seed.

Use clean seed.

Seed-Lok plugging.

Row-unit disks not turning.

See “Row-unit disks not turning

freely” in this Troubleshooting chart.

Plugged row-unit seed tube.

Lift up planter, expose bottom of

seed tube and clean out.

Worn/rusted sprockets and/or chain

idler.

Check and replace any worn/rusted

sprockets or chain idlers.

Partially plugged row-unit seed

tube.

Lift up planter, expose bottom of

seed tube and clean out.

Lack of proper seed lubrication on

seed.

Refer to Seed Lubricant, page 66.

Use of excessively sticky or wet

seed treatment.

Check your treatment.

Uneven seed depth

Excessive field speed.

Reduce field speed.

Planting conditions too wet.

Wait until drier weather.

Incorrect coulter depth setting.

See coulter adjustments, page 32.

Excessive or improper row unit

down pressure spring setting.

See 25 series row units, page 33.

Damaged seed tubes.

Check seed tubes for damage.

Seed-Lok building up with dirt.

Row-unit not penetrating low spots.

Adjust row-unit, see instructions

beginning on page 33.

Rough planting conditions.

Rework the field.

Seed firmer not in place and set to

correct tension.

Refer to Keeton Seed Firmer, page

48.

Row-unit disks not turning freely.

Row-unit plugged with dirt.

Clean row-unit.

Planting conditions too wet.

Wait until drier weather.

Seed-Lok is plugging row-unit.

Failed disk bearings.

Replace disk bearings.

Bent or twisted row-unit frame.

Replace row-unit frame.

Partially plugged row-unit seed

tube.

Lift up planter, expose bottom of

seed tube and clean out.

Problem

Cause

Solution